A new Faro Gage arm has been launched, with a new slimmed-down form, greater accuracy, and a simple two-button user interface.

Faro’s high accuracy Gage arm has been around for a good few years now, and unlike its cousins for reverse engineering, physical form capture and such things, the Gage has been focused on measurement – typically looking to replace traditional CMMs.

The idea is to provide a digital equivalent of that drawer of micrometers, callipers and other gauges we’re all familiar with.

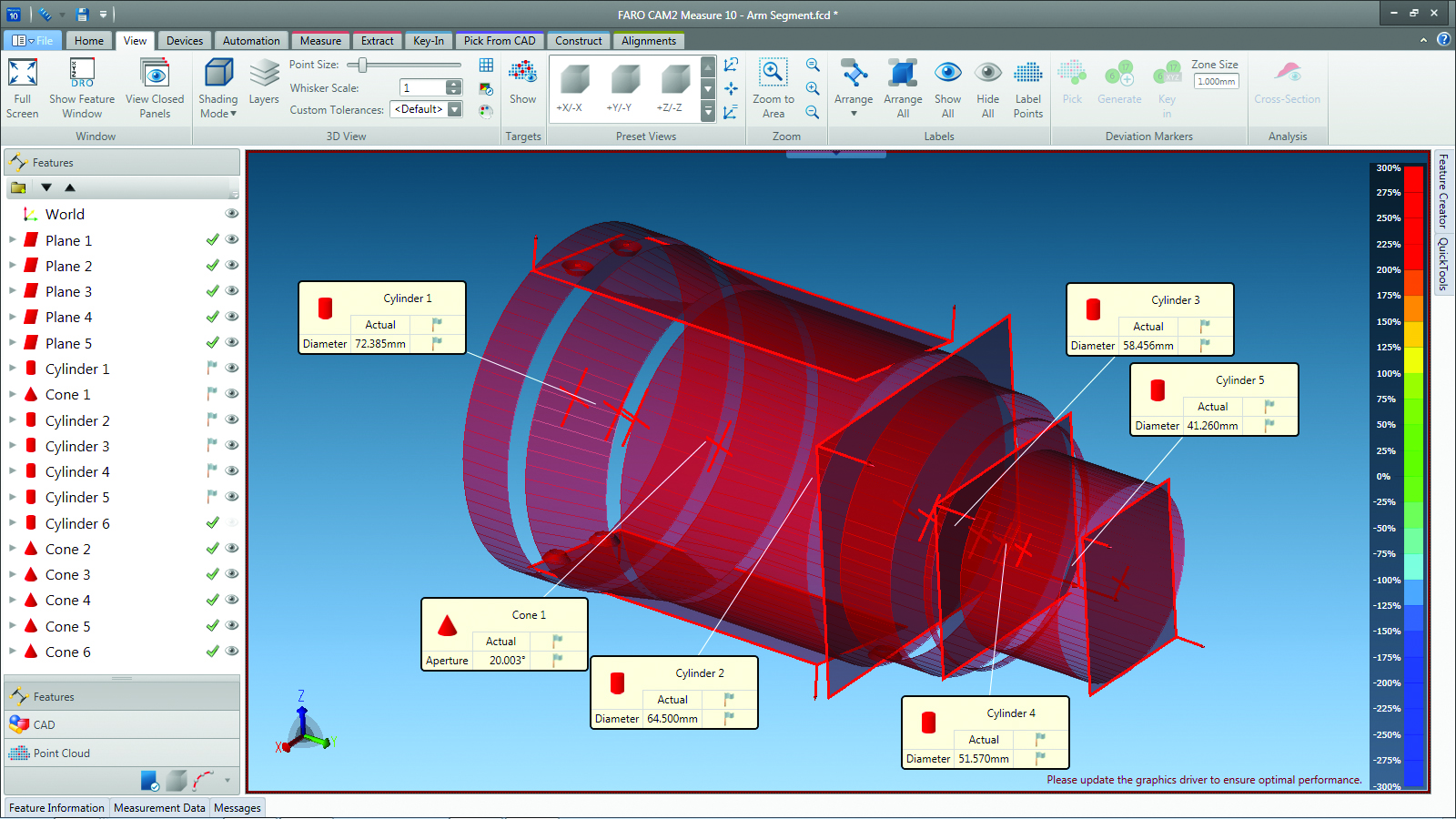

The system is comprised of a high accurate measurement arm along with a set of software that gives you the tools you need to make the measurements you want.

The redesigned Faro Gage arm looks like a little more streamlined than its chunky predecessor, but brings you a 20 per cent longer reach (1.5m working sphere compared to 1.2m). If you’re curious about just how accurate this bad boy is? The answer is around the 0.018mm mark.

There’s a universal quick mount that “ensures compatibility with a variety of mounting options that allows it to be set it up anywhere, including on-machine.”

A simple 2-button design, 6-point articulation and built-in counterbalance deliver exceptional ease of use and claims fatigue-free operation.

Of course, key enabling this is Faro’s metrology software, including Faro’s CAM2 Probing software which provides the simple contact based measurement for the Gage.

“When it comes to measurement equipment value; accuracy, portability, speed and affordability matter,” said Faro product marketing VP Michael Carris.

“Too often machine shops rely on expensive and hard-to-use fixed CMMs that take up valuable floor space or a multitude of hand tools that slow down the process. The Gage eliminates these inefficiencies.

“As a result, inspection bottlenecks are greatly reduced, measurement accuracy is improved, and operator variability is significantly minimised.”

Carris added that the new model has been designed with small to medium companies in mind.

“For machine shops, quality problems, imprecise measurement, scrapped parts, extended wait times and customers part rejections all contribute to unnecessary expenses that become more critical during these trying economic times.”

“The Faro Gage allows for more streamlined processes, significant waste reduction, and quick return on investment. Backed by Faro’s 40-year history of superior portable measurement experience, Gage allows more companies to benefit from lean manufacturing practices and will be employing the new industry standard in compact performance and affordability,” he concludes.