A consortium of companies developing a system for increased material efficiency in ceramic and metal additive manufacturing has received £1.7m for its SAMRCD (Scalable AM Rule Creation & Dissemination) project from the UK government,

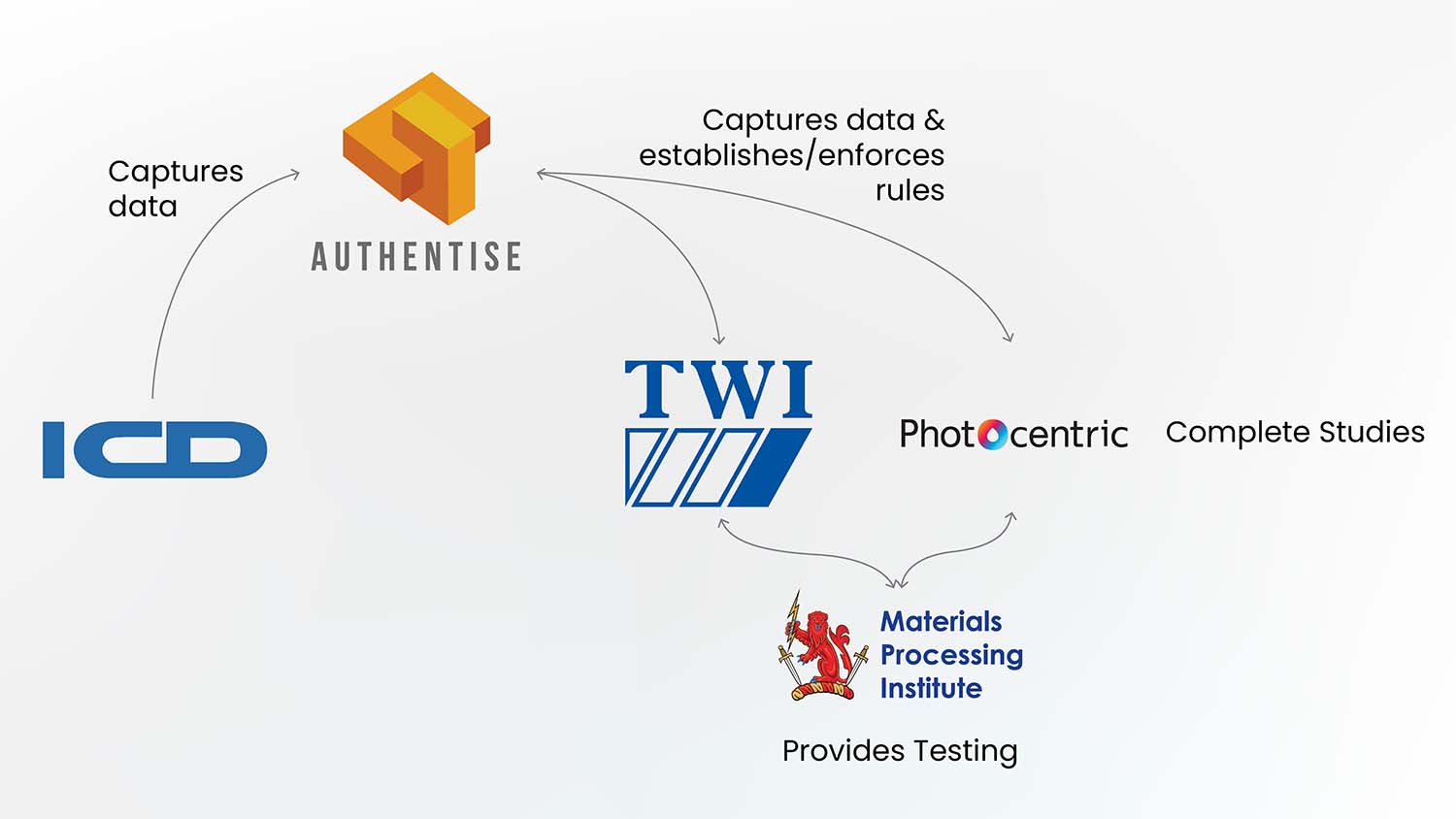

Led by Authentise, the team has been awarded a the grant by UK Research and Innovation’s Transforming Foundation Industries’ challenge, delivered by Innovate UK.

The goal is to continue its development and validation of scalable digital tools to identify, create and enforce rules that reduce direct and indirect energy consumption and increase material efficiency in ceramic and metal additive manufacturing.

The partners include 3D printing manufacturer Photocentric; ICD, provider of metal powders; Materials Processing Institute, providing research and innovation services for the Foundation Industries; and TWI, the membership-based research and technology organisation.

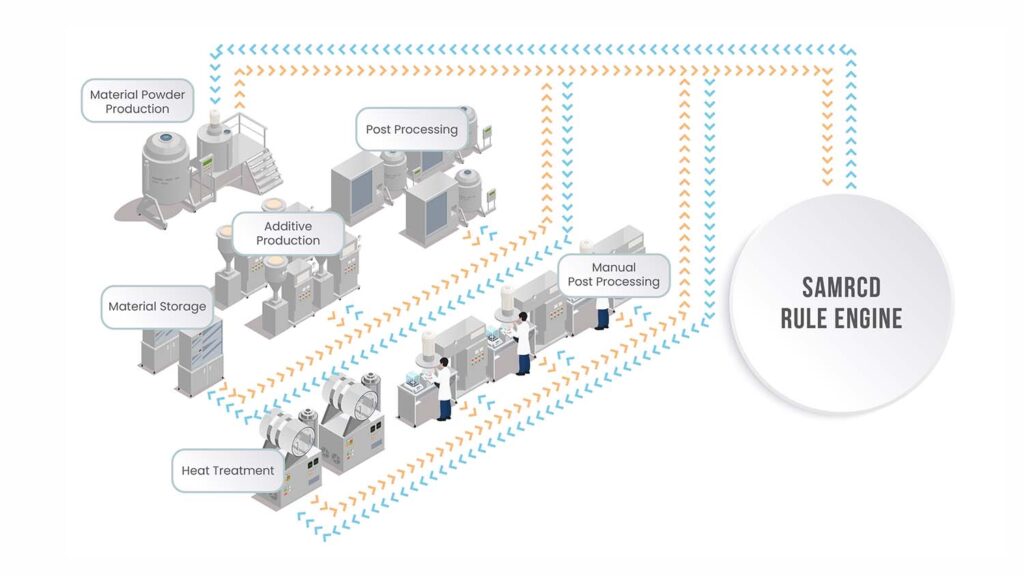

During the SAMRCD project, Authentise is developing tools that enable users to identify operating rules through literature, standards, experiments, and deep learning, and enforce these rules on future production to ensure more efficient and repeatable products. To do so, the partners will integrate direct data capture from across the materials and production value chain.

Photocentric and TWI will test these tools in metal and ceramic AM studies that aim to reduce energy and material use in production. The material and related production data will be supplied by ICD and results will be validated by the Materials Processing Institute.

“Continuing studies and analysis will only achieve so much,” said Authentic CEO Andre Wegner. “Digital tools that can monitor, analyse, predict and alert a range of impact and deviations in standard operating procedures are fundamental to improve manufacturing processes, increase repeatability and reduce resource intensity of the process.

“Additive manufacturing rightfully has a reputation as a clean technology, but there is so much more to be done.”

“This is the first time that the impacts of actions are considered across the entire value chain, from material production to final part,” added Carl Hauser, section manager for TWI laser additive manufacturing.

“The SAMRCD team includes partners from across that spectrum. Together, we are able to increase the scope of in-process control from very specific in-machine processes to end-to-end monitoring. Changing material production parameters slightly may have a material impact on part production success, for instance. Thanks to SAMRCD we won’t only know that but will be able to take direct action.”