Stratasys and Keyshot have partnered to make colour 3D printing the reality it has always promised. Stephen Holmes looks at the technology and whether it will finally solve the age-old problems

Full colour 3D printing has more often than not failed to live up to the hype. Designers have regarded it as an expensive folly, one that creates overly expensive, hard to print parts they wouldn’t put in front of their grandmothers, let alone a client.

Even Stratasys’ Polyjet technology – capable of producing thousands of colours, with Pantone verification and extreme detail – has had trouble expanding the market because of the nightmare workflow for applying true colours to solid 3D CAD models.

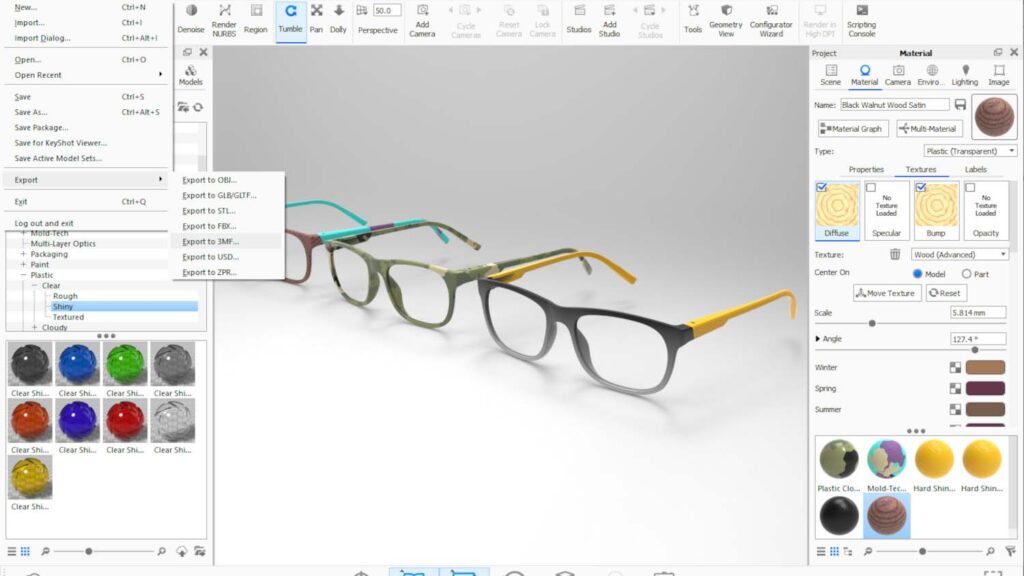

Until now, that is. November 2020 sees Stratasys officially launch its partnership with visualisation experts Luxion and its software Keyshot to create a new workflow that exports print-ready 3MF files.

Keyshot is the magic ingredient in all this: While the 3MF file allows the export of the geometry, colour and bump map data in a neat package, it’s the visualisation software that unwraps the model, automates the process and creates a useable workflow.

The goal of this is to create a synergy between the concept on screen and a physical model, allowing for Colour Material Finish (CMF) prototypes to be produced quickly in bunches for decision making, integrating into the wider workflow much earlier than normal.

“For both KeyShot and Stratasys, it’s all about a single question: How can we get the designer to that ‘Yes’ moment faster?” says Luxion VP of product Derek Cicero.

“The more you can visualise around Colours, Materials and Finish, and the sooner you can do it, the more confidence a designer has that they made the right choices.”

In KeyShot, this is about getting from a CAD model into experimentation with CMF in a few clicks to see what works, and then exporting it via renders and animations.

“The decision-making process is hyper-streamlined,” explains Cicero. “It’s what has made KeyShot a major tool for designers for 10 years.

“When you add the ability to have ‘same day’ physical samples that reflect those colours and finishes, you now have the ability to build-out and refine an entire product go-to-market: the marketing shots, the website, the packaging and the ‘physical product’ before you even manufacture a ‘real’ prototype.”

Made Physical

“Since the J750 came out, we’ve been able to print complex geometries with colours, materials and finishes, but it was always too complicated. You would need to know 3dsMax, and ZBrush and Rhino to do it – the files were huge, would crash computers,” admits Stratasys product manager Lior Elgali, a man who has produced some of the outstanding full colour models that Stratasys uses to showcase what its hardware is capable of.

Previous attempts to solve the pipeline problem through a partnership with Adobe failed, primarily because the file sizes it created were unusably huge.

It’s unsurprising then that CMF prototypes remain towards the end of the design workflow, long after geometry and functional prototypes and many of the key decisions have been decided through onscreen tools.

While a colour or material change is easy to action in a render, it can be much more effort to change in a physical prototype.

“That’s the difference between a $5 and a $500 prototype!” Laughs Elgali. “Testing out two different pieces of wood means sourcing another wood, or printing another vinyl wrap.”

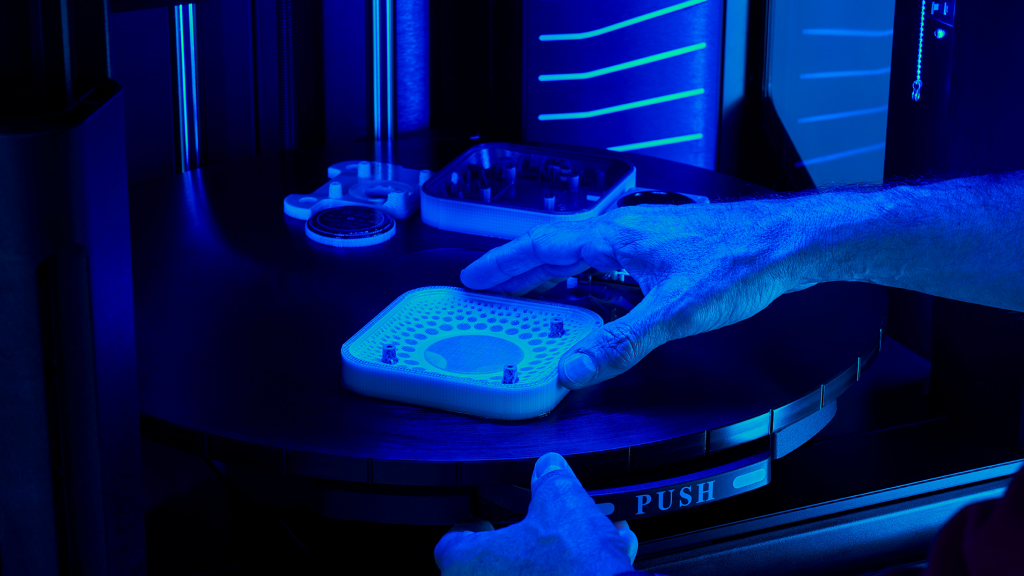

The new speed of the Stratasys J55 3D printer workflow now means that there is a true alternative: being able to pick out a selection of woodgrains in a design meeting, and the next morning having four physical prototypes to pick-up, hold and look at – pushing CMF decisions earlier into the product development.

From the initial Beta roll out, Stratasys says it saw customers printing ‘a lot more parts’, primarily because they were used to the Keyshot workflow. “It makes so much sense: I already have the CMF data [in Keyshot], I don’t need to recreate it!” says Elgali.

Yet as you would expect, not every material can be replicated through Polyjet 3D printing. Some transparency settings, metallics and mirror finishes found in Keyshot are beyond the capabilities of the hardware at present.

“Of course, it will depend on what you are trying to accomplish,” says Cicero, adding that with product examples such as the Priority Design’s wireless speaker [see images] or a phone case, you can get incredibly accurate results, “so that people would do a double take if you replaced the ‘real’ version with the 3D printed one.”

“While you aren’t going the get the smoothness of leather or wood grain, you are going to get a very accurate look for decision making purposes. For prints that are doing plastics, it’s going to be very close to the real output.”

Fast Progress

The improvements made through Beta testing were considerable, and both parties assures us it won’t end there.

As with Stratasys’ prior work providing colour correct Pantone verification, its team is hard at work adding multi-materials ability to the J55 platform.

The addition of the Stratasys Agilus flexible material and the snap-fit, heat resistant Digital ABS, when supported by the 3MF file, will allow shore hardness to be applied to models as well as all the colour, geometry and texture – meaning even greater potential for early CMF models.

“In utilising the 3MF format, we’re pushing to get the screen and print experience to be as closely aligned as possible, however these will always be complimentary tools,” says Cicero.

“Whereas KeyShot can give you accurate lighting of a coloured metal finish in a store environment with IES lights, the ‘correct’ height for a button on a game controller needs to be tactile.”

Yet given this is only the first release of Keyshot featuring the export for the J55 3D printer, Cicero is positive about where this is heading, concluding that, “it’s possible to envision that in five or six years we will be at a point where many 3D printed products are indiscernible from their manufactured counterpart”.

The Reality

Key to the Beta testing was the design team at Priority Designs, in Columbus Ohio, which put the J55 through its paces, fitting the 3D printer into a workflow that already included Keyshot.

The process, says senior industrial designer Ryan Berger, allowed Priority Design to do a lot of exciting things with CMF that previously they’d been unable to integrate earlier into the development.

“Instead of looking at a wall full of flat renderings, we’re able to pick up and experience the product in a physical way – I think that’s its biggest value,” says Berger.

In terms of workflow, Keyshot is the element that allowed Berger to get the most from the J55 in terms of experimentation. “Just the ability to quickly represent the textures in a way that’s upfront, before you’ve got to make the [time] investment in CAD,” he explains.

For the sake of the concept, the team produced versions of the speaker in a wide variety of materials, fitting five speaker units onto the J55’s build tray at a time. The parts impressed the design team, but the more they used it, the more they found new uses – including being able to simply represent displays on prototypes in a convincing way thanks to the high resolution.

“There were a lot of people in the building that had the same feeling about a colour machine – why would we ever use that?” says Berger. “The finish, certainly, is great: It has none of that sort of powdery look that we’ve experienced with other machines.

“I think it’s a big step forward and has done a great job of winning over our design staff with these prototypes. You need to get it in someone’s hands before they really understand, and then when they do, they start to think of all kinds of ways to utilise the machine.

“It’s not a 1:1 Match exactly, but it’s close enough that I’m excited about showing these models to my clients.

Berger concludes: “It’s a great tool that adds to the ability to create something that’s so close to convincing that you eliminate some of the questions and can just focus on the design.”