Digital transformation: look beyond necessity and focus on business advantage, PTC CEO Jim Heppelmann tells Liveworx 2020 audience

What a difference a year makes. When PTC president and CEO Jim Heppelmann delivered last year’s PTC Liveworx keynote, he addressed a packed house at the Boston Convention Center from a striking multi-zone, multi-level stage set that wouldn’t have looked out of place in a Broadway show.

By contrast, this year’s keynote was a far more subdued affair, delivered over the Internet from Heppelmann’s Boston home.

As he wryly observed, “It seems crazy I’m talking to you from my home office. But the past few months have been crazy across so many different dimensions.”

Despite the unusual circumstances, Heppelmann delivered a sensitively judged, well-structured keynote, clearly intended as a message of hope to PTC’s industrial customer base.

In keeping with the technology sector trend of recent years, the presentation put customer success stories front and centre, but Heppelmann didn’t shy away from acknowledging the human and economic cost of Covid-19 and took time to pay tribute to the vital role played by frontline workers in recent months.

Nor did he miss the opportunity to thank his own team. During the pandemic, he said, PTC employees working from home have successfully closed the company’s fiscal second quarter, met software release goals and generally kept its global business running.

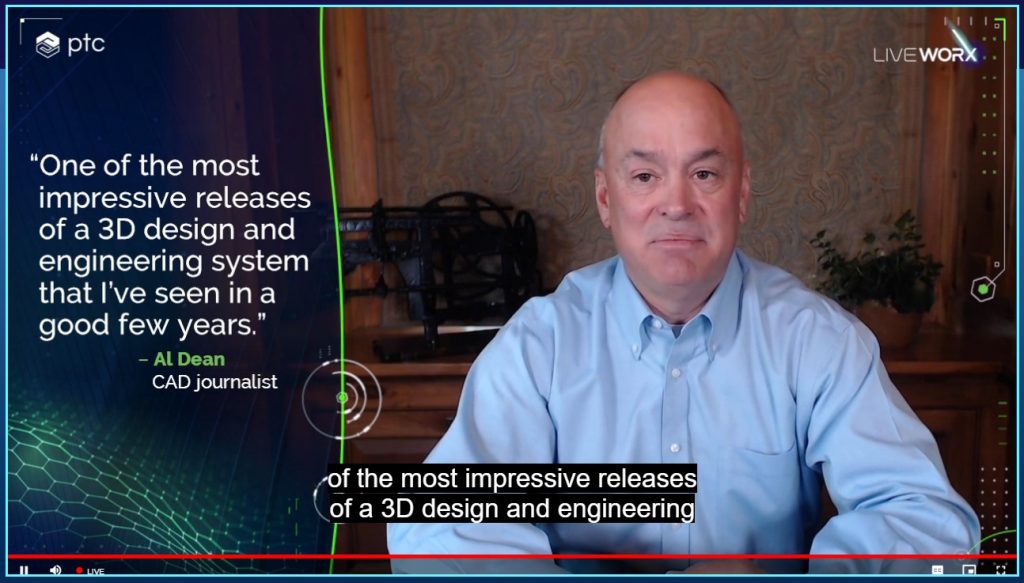

Special mention was made of the recent release of Creo 7, “the largest release since we introduced Creo to you a decade ago.” Here, DEVELOP3D editor in chief Al Dean got a namecheck from Heppelmann, for his recent assessment of Creo 7 as “one of the most impressive releases of a 3D design and engineering system that I’ve seen in a good few years.” (You can read our full review of Creo 7 here.)

The core of Heppelmann’s keynote focused on four main lessons learned from the recent crisis, and how these might be used as the basis for developing “thriving skills” over the months and years ahead.

The first of these “thriving skills” is workforce mobility and resiliency – in other words, using cloud technologies to ensure that workers have access to the tools and data they need to get work done, regardless of their location.

According to Heppelmann, PTC’s $470 million acquisition of Onshape last November doesn’t just give PTC a full suite of software-as-a-service CAD and PLM tools, but also the technological foundation to deliver SaaS versions of all of its major products in the future.

This platform has been named Atlas by the company, “because it will ultimately carry the entire PTC SaaS world on its shoulders.”

It is these kinds of cloud capabilities that have kept design work moving ahead at Onshape customer Garret Motion, an automotive supplier and at PTC Windchill customers, robot maker GreyOrange and medical equipment specialist Fresenius Medical Care.

The second skill is flexible and innovative supply chains. In a world where many companies work together on the design and manufacture of a product, said Heppelmann, software incompatibilities continue to be a burden.

Again, a cloud-based product like Onshape enables partners to collaborate more easily on designs, as seen in the ventilators produced by a consortium of local companies in El Salvador led by Francisco Gandia University and at electric vehicle specialist e.GO Mobile in Germany. (Although, in this latter case, Heppelmann’s ‘survive and thrive’ message may not be entirely apt, since the company filed for insolvency protection in April and its future hangs somewhat in the balance.)

The third skill is enabling frontline worker connectivity and collaboration – an opportunity for Heppelmann to showcase PTC’s Vuforia augmented reality (AR) applications.

“Like a growing number of you, I’m a big believer that AR is going to bring massive productivity advantages to those enormous ranks of frontline workers,” he said.

Automotive giant Toyota Motor Company, for example, is already using Vuforia Chalk, so that production engineering staff can remotely oversee the subcontractors who handle installation of new manufacturing lines and maintain existing assets and facilities around the world.

In the UK, PTC worked as part of the VentilatorChallengeUK consortium, providing AR technology so that experts could capture the crucial assembly steps and processes involved in building ventilator systems and share them with workers in the factories of consortium partners who have never made ventilators before.

Finally, there’s remote monitoring, using the Internet of Things (IoT) to keep plant floor machinery up and running on factories floors and smart products serviced once they’re bought and installed by customers.

At medical equipment company Elekta, for example, IoT connectivity has reduced the time it takes to make part changes on radiotherapy machines from 60 hours to 15 hours and around half of equipment problems are now resolved remotely.

At Autoliv, which makes car safety equipment such as airbags and seatbelts, IoT is used for real-time detection of problems in product quality and reliability.

As Heppelmann concluded: “While the Coronavirus crisis is a terrible health and economic problem, it’s definitely accelerating the movement towards digital technology like IoT, AR and SaaS – the types of technology that PTC has been prioritising and that make our company so unique.”

“When uncertainty and disruption become the expectation, then accelerating digital transformation is the ideal response,” he continued. “It’s time to take stock of what works and what doesn’t – and to think beyond necessity, to business advantage.”

Jessica Twentyman is a journalist with a 25-year track record as both a writer and editor on national newspapers and IT trade titles.

She is a regular contributor to the Financial Times and The Economist Intelligence Unit (EIU), among others, and a Consulting Editor on Diginomica.com, I-CIO.com and DEVELOP3D.