Sciaky has announced that its electron beam additive manufacturing (EBAM) surpasses 40lbs of titanium per hour, making it the highest deposition rate in the world for industrial metal 3D printing, according to the Philips Service Industries subsidiary.

This EBAM deposition rate was achieved by Saint Exupéry Institute for Research in Technology in France while conducting research for its Metallic Advanced Material for Aeronautics (MAMA) projects.

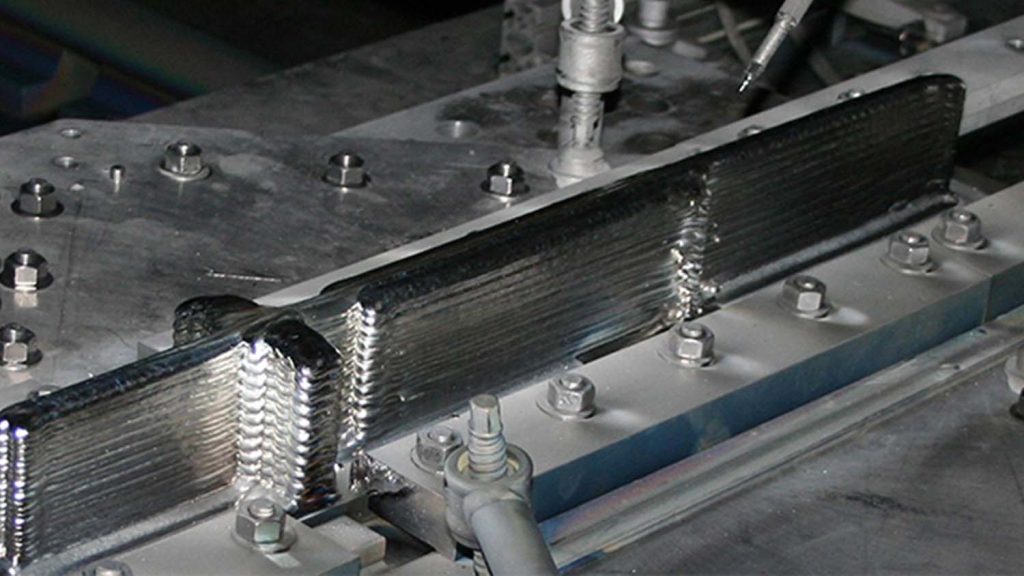

Launched in 2019, one of MAMA’s initial goals was to combine die forging with metal 3D printing to develop a new process for manufacturing titanium aircraft parts.

To date, Sciaky said, its EBAM has deposited over 330 lbs of Ti-6AI-4V (titanium) for three different MAMA applications.

The Chicago-based provider of metal additive manufacturing solutions said that additional projects are planned for 2022 and beyond, with a groundswell of support to adopt these new processes into production.

Airbus and Aubert & Duval are amongst the other process contributors for this particular initiative of the MAMA project.

“Sciaky is excited about EBAM’s new deposition rate milestone,” said Sciaky CEO Scott Phillips.

“We are committed to discovering new applications for EBAM that will help manufacturers save significant time and money on part production, as well as improve part quality,” he went on.

Sciaky’s EBAM systems should be able to produce parts up to 19 feet in length, which should make it the most widely scalable metal additive manufacturing solution in the industry, in terms of work envelope.

The company stated that the innovative closed-loop control is the primary reason its EBAM 3D printing process delivers consistent part geometry, mechanical properties, microstructure, and metal chemistry.