Siemens Gas & Power keeps thousands of homes and businesses up and running. The Gas & Power division, one of three Siemens operating companies, owns compressors, turbines, and generators across the globe. When those gas turbines need repairing, engineers at the Siemens Gas & Power division must efficiently cut into them with a circular saw to maintain the system. Since the housings have a complex contoured design, a standard flat skid-plate circular saw does not suffice.

In the past, the team remedied this by purchasing standard circular saws, shipping them to job shops in the Philippines for custom-contoured plates, and then shipping them back to the United States for reassembly.

This was not a scalable solution, as engineers would wait more than three weeks to receive their customised hand tools.

Off the shelf won’t cut it

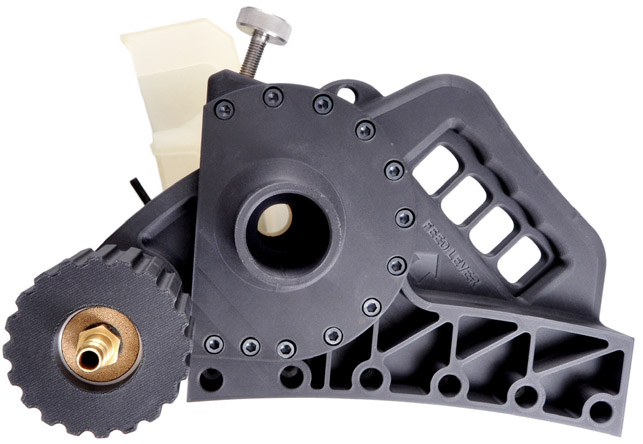

Siemens engineers determined that most circular saw components could be printed to accurately match the contour of the turbine. The team purchased and began to use Markforged’s industrial composite X7 printer, after deeming it the best option for the job. “We bought an off-the-shelf motor and the blade, but everything else was custom built,” says Siemens Gas & Power engineer, Sam Dicpetris.

“The parts were initially tested in Onyx, a nylon base with chopped carbon fiber, and then reinforced with continuous carbon fibre to stiffen the structure. Not only can we make necessary custom tooling, but also parts we haven’t been able to produce with traditional methods of manufacturing.”

“The continuous carbon fibre strength is really, really impressive. When you have a plastic part that feels and looks like a plastic part, but it has this internal strength of something much different, it sets everybody up for a shock,” Diceptris continues.

With the printed saw, turbine repairs in the field now take a matter of days instead of weeks. “We can cut and make a tool that fits the exact contour of the things we’re trying to cut, which is different from anything that you can buy off the shelf,” Dicpetris says.

Siemens Gas & Power not only reduced the time to make these tools from weeks to days, but also saved money while remaining cutting edge in a competitive industry.

Dicpetris estimates the team saved over $8,000 from only this one custom circular saw, as well as hundreds of thousands of dollars on other applications.

Once the engineering team had tackled this project, they began to adopt a design for additive manufacturing (DFAM) approach to problem-solving. Now, engineers at Siemens Gas & Power consider 3D-printed parts first, ahead of traditionally fabricated components, when they’re needed.

Siemens Gas & Power – where next?

With over 100 engineers using Markforged technology, Siemens Gas & Power engineers aren’t slowing down. They are constantly exploring new applications, such as modular fixtures for turbine blades, to enhance their product line and workstream.

Their printers are running almost 24/7, with little to no downtime. The company has also utilised its Metal X to create custom one-off parts and its trusted external machine shop is also adding a Metal X internally in order to keep up with the company’s need for fast turnaround times on metal components.

Vital turbine repair jobs being transformed by 3D printing parts locally

Default