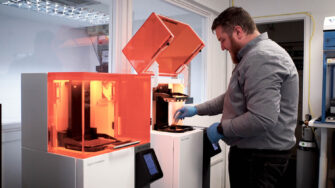

New production-capable materials – including a novel flame retardant, 150C HDT material, and others with improved long-term mechanical performance have been announced by 3D Systems for its Figure 4 system.

Four new high-performance resins for the Figure 4 3D printers are focussed on end-use part manufacturing and prototyping applications.

Figure 4 High Temp 150C FR Black, Tough 65C Black, Tough 60C White, and Rigid Gray are all held up by 3D Systems for their long-term mechanical performance and stability in indoor and outdoor environments – having reportedly been tested for the equivalent of 8 years indoors and one and a half years in outdoor environments.

Figure 4 High Temp 150C FR Black (above) is a rigid, halogen-free, fire retardant resin ideal for production plastic parts – especially in aerospace and automotive.

The material is UL94 V0 rated at 2mm or 3mm thickness for electrical components and printed circuit board covers and housings, while also compliant with relevant US Federal Aviation Regulation at 3mm thickness.

Figure 4 Tough 65C Black possesses high elongation at yield (6.6%) which delivers better snaps and clips, making it ideal for applications such as brackets, covers, snap fits, structural and load-bearing parts, and custom fasteners.

Figure 4 Tough 60C White, similar in overall performance to the Tough 65C Black, and can be sterilised using common methods while maintaining its mechanical properties, colour, cytotoxicity, and dimensional stability.

The new Rigid Gray prototyping material is similar to the previous Figure 4 PRO BLK 10 material, ideal for static, rigid parts, with the benefit of the grey colour making the visualisation of text, texture, and fine details easier, and secondary processes such as painting and metal plating easier.

Additionally, 3D Systems’ 3D Sprint software has been updated to enable high-density part stacking and new strut support structures, which it says facilitates a ‘40% improvement in productivity’.

“Our materials scientists created these latest enhancements for our Figure 4 portfolio to help our customers produce parts that not only enhance performance but improve productivity,” said Dr. Edwin Hortelano, senior VP, materials engineering & development, 3D Systems.

“The combination of materials, 3D printing technology, software, and deep applications expertise allows 3D Systems to deliver industry-leading additive manufacturing solutions that accelerate time-to-market and enable competitive advantage.”

General availability of these materials is planned for the middle of June 2021.