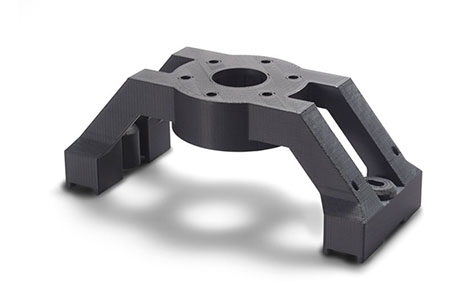

Stratasys has unveiled several new durable, temperature and chemical resistant FDM thermoplastics for additive manufacturing, these materials can accommodate high temperatures and challenging requirements common on the factory floor.

For the Stratasys F900 there is a new PEEK-based Antero 840CN03 material, formulated to create custom tooling and parts with consistent electrostatic discharge (ESD) performance.

Additionally, Diran 410MF07 and ABS-ESD7 have been launched for the Stratasys F370 3D printer – with Diran a tough nylon-based material formulated by Stratasys, and ABS-ESD7 built for static-sensitive applications and previously only available on the Stratasys Fortus line.

“We see growing adoption of 3D printing in production environments, yet engineers and designers struggle with thermoplastics that just can’t match the extreme requirements of manufacturing-based applications,” said Stratasys manufacturing solutions VP Adam Pawloski.

“Our thermoplastics can remove these barriers to accelerate adoption of 3D printing in manufacturing settings, allowing users to design and create faster, while minimizing costs often associated with traditional approaches.”

The announcements arrive alongside news that Stratasys has launched a new flagship PolyJet 3D Printer the J850.