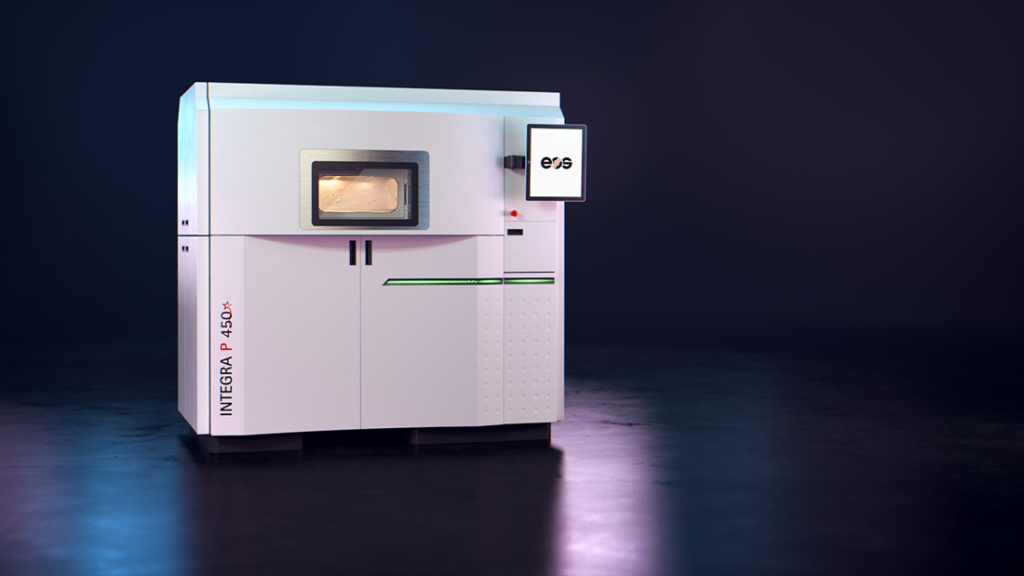

EOS North America has announced the launch of its Integra P 450 mid-range temperature, powder bed, polymer 3D printer.

The SLS platform is scaleable to customer needs, bridging the gap between the company’s small series production printer and a full-scale serial additive manufacturing platform.

Featuring process temperatures of up to 300°C, the new model offers a broad range of SLS material flexibility combined with an 8-zone quartz heating system, for independent zone control for enhanced precision, consistent quality, and more efficient use of build volumes.

The EOS 3D Printer also has an improved process chamber design that enhances thermal uniformity during builds for production-caliber performance.

Its ‘future-proof’, modular design, that includes an exchangeable optics tray and build volume, was created with extensive input from service professionals in order to enhance serviceability and reduce downtime.

EOS North America has also managed to integrate a thermal imaging camera that provides real-time thermal analysis of part beds and recording of the entire build.

“Every aspect of the Integra P 450’s design – from its serviceability and material flexibility to the thermal imaging camera and workflow-based approach – was thoughtfully measured against customer feedback to create a machine that can easily scale and bridge the gap, from R&D and prototyping, to serial production,” said EOS North America COO David Leigh.

EOS North America is a business of EOS, and acts as an independent company, adding to the EOS line-up of polymer 3D printers