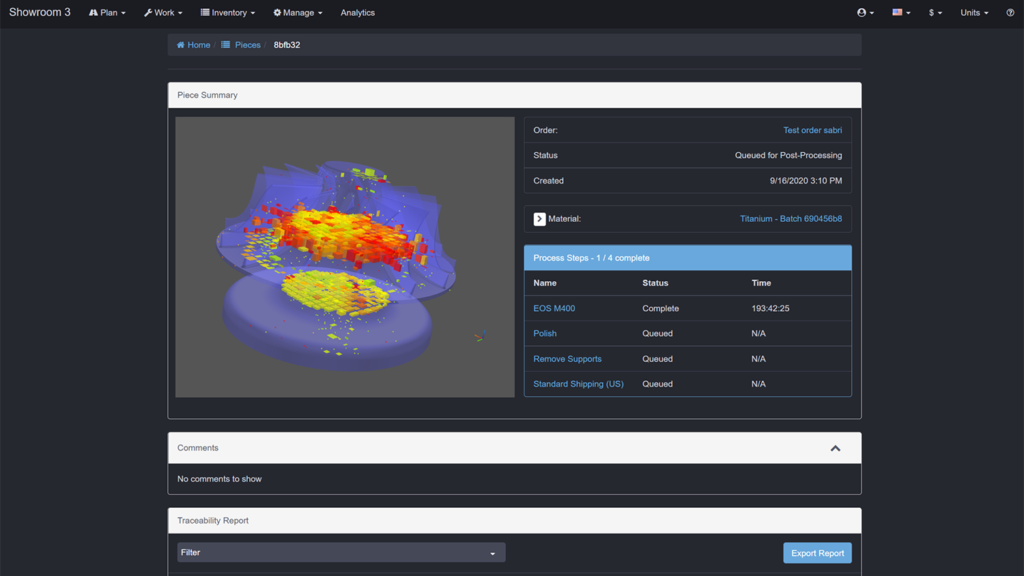

Nebumind has announced its integration into the Authentise Manufacturing Execution System (AMES), producing ‘digital twin’ visualisations, which can fuse machine parameters and sensor data with the original part geometry.

The addition of Nebumind’s visualisation capabilities into Authentise’s data-driven workflow tools for additive manufacturing, aim to help users identify problem zones of each part more easily and lead to less time intensive and more accurate inspections.

In addition, real-time alerts generated by the Nebumind system inside AMES should help the user address any deviations during the process, reducing waste.

Since AMES already captures data from the machines and manages the printable geometry, the system passes this information on to nebumind automatically, saving the user from locating and uploading this information separately.

The insight generated is appended to the existing AMES part report to ensure end-to-end traceability.

“Additive users need to be able to review data at a single glance,” said Nebumind CEO Franz Engel.

“To date all they are given is long and complex tables of sensor data that are difficult to make head or tail of. Thanks to the integration with AMES, we can get this data automatically and fuse it with the shape being produced.”

Engel says that this way the user can see an instant heatmap of potential problem areas, and ‘deep dive into every voxel’ to help understand the underlying data if necessary.

The goal is that users can identify rework needs faster – Engels reports 10 times faster with this workflow – and reduce production rejects by up to 90 per cent.

“Integrating this view with AMES makes sense, since that’s where production is managed, and data is held,” he continues. “We’re excited to be collaborating with Authentise to make the additive process more seamless and reliable for users.”

“We’re excited to be welcoming Nebumind to the Authentise platform,” says Authentise CEO Andre Wegner.

“Together we can accomplish the goal of a seamless, failproof additive process. The collaboration proves once again that trying to do so single-handedly leads to failure and harms customers: For years they have had to put up with sub-optimal data analysis, in several different software tools. Now it’s all in one place, instantly accessible, and cutting edge.

“This partnership proves once again how much we can move this industry forward if industry leaders work together, and not against one another.”