A visit to Mimaki has rekindled Stephen Holmes’ appreciation of colour in 3D-printed prototypes. But, as he reports, recent advancements make colour worth considering for engineering models as well as for CMF workflows

Few locations showcase an abundance of colour like the city of Amsterdam during its annual Pride Weekend.

Once through Schiphol airport, filled with Dutch orange football shirts heading off on vacation, and a riot of rainbow flags arriving in time for the party, we headed to printer manufacturer Mimaki’s European headquarters, where we found the Japanese company putting on an equally colourful display.

Mimaki-s UV-cured inkjet printing is an evolution of the brand’s 2D large format printers, which fill most of the demo space at its European base. On show are the company’s most creative innovations for printing designs directly onto materials such cotton fabrics, clear polymers for window displays, and even 3D objects such as pens and water bottles. Mimaki’s 2.5D technology is built to operate in high turnover production environments and shares much of the same mechanical design DNA as its 3D printing brethren.

Mimaki’s two 3D printers, the 3DUJ-553 and smaller 3DUJ-2207, occupy their own segment of the building, surrounded by an array of fantastical 3D models, from medical guides to magical statues, and from pairs of sneakers to architectural models. The company offers no ‘functional’ materials for stronger or elasticated parts. Instead, the focus is on reproducing over 10 million colours in extreme detail.

What you can do with those colours is impressive but comes with some limitations. While fast post-processing of Mimaki parts makes them more robust than you might expect, they’re not designed to stand up to high temperatures, for example, and elements such as hinges will show signs of wear after time. However, where this technology excels is in putting across an idea, selling a concept or explaining a process as a tangible part.

Overcoming obstacles

Colour 3D printing has been around for over a decade, yet uptake has been restricted by two factors. First, there’s the faff involved in digitally colouring a CAD model and getting that to work. Second, there’s the quality of what comes off the printer.

There have been significant improvements in both respects. Output from today’s machines is far more realistic. The availability of colours, the ability to create natural hues and the introduction of clear materials all represent significant steps forward from the washed-out, powdery finishes of older generation Z-Corp machines. Software workflows have improved, too. Early efforts typically involved enormous file sizes and a lot of manual involvement.

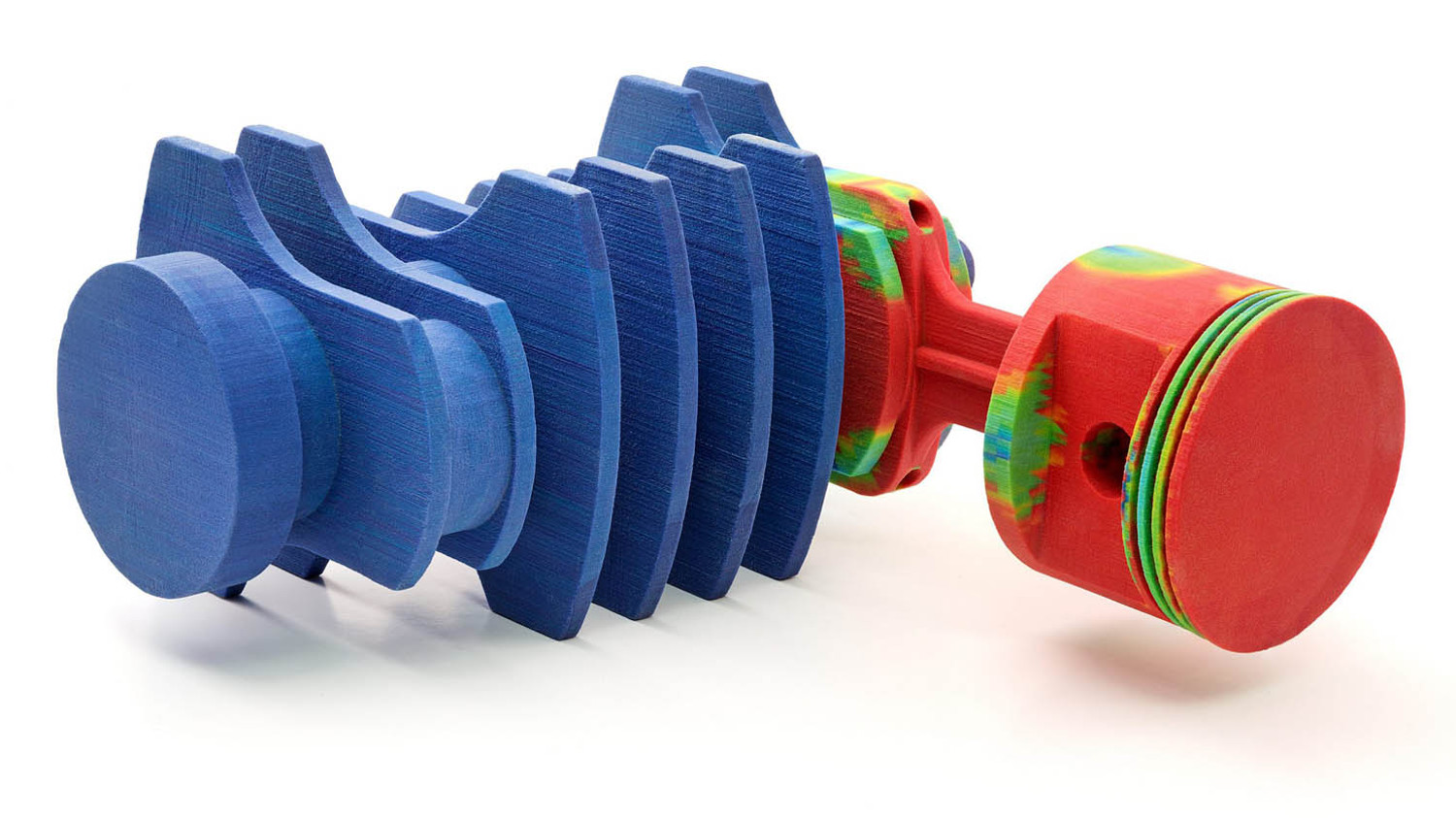

In pursuit of a more seamless Colour Material Finish (CMF) prototyping workflow, for example, Stratasys has worked alongside visualisation expert Luxion to develop a simple, full-colour export from Keyshot renders for its J-Series 3D printers. This print data comes packaged in a 3MF file format, superior to STL files and capable of containing the colour and texture data for realistic prints. Since the Stratasys-Keyshot launch, more workflow options making use of the 3MF file format have become available, such as via Autodesk’s Netfabb.

Using this process, Autodesk’s Boston technology centre has been experimenting with colour prototypes, using models designed in Fusion 360 and using Netfabb to apply and export colour data to its in-house Mimaki 3D printer to produce the final models.

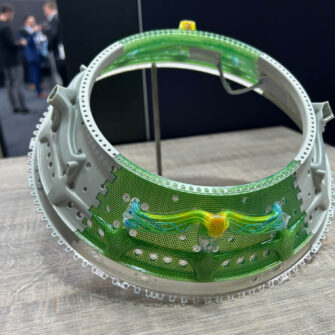

Scale models are still valuable tools for explaining designs and getting buy-in from stakeholders, and for parts with complex lattice infills or electronic layouts, or for displaying the results of flow simulations, a colour 3D printer really brings a proposal to life.

After all, tasks such as explaining the effects of a mould flow simulation or the efficiencies of an internal lattice cooling structure are a lot easier when a model that illustrates the advantages in full colour can be laid on a table, passed around and inspected. On a less complex level, colour can be really useful for labelling a model or distinguishing different elements in a prototype.

In this way, a journey into colour can also be a better way to lay out the facts in black and white, so that everyone can see and understand what’s going on. Easy on the eye and easy on the brain.

Stratasys J850 Prime

The flagship of Stratasys’ Polyjet UV-cured resin 3D printers, the J850 Prime comes with Pantonevalidated colours and multi-material abilities that give flexibility for prototyping a wide range of products.

With high accuracy, textures can be added to parts to enhance the realism, or simply add fine text or detail to a print – like digital displays, woodgrain or stitching – bringing even more options, in addition to the halfmillion colours it can output.

A wide material selection offers impressively translucent and rubber-like options, while a range of biocompatible materials and digital ABS for highimpact strength and heat resistance offer functional prototyping ability.

If it’s colour that you’re looking to bring in-house, Stratasys says it can produce full-colour models straight from your Keyshot render in 20% of the time it takes to produce a traditional painted model. Once you fill up the 490 x 390 x 200 mm build platform with options, then this new ability for design review only takes on more promise.

www.stratasys.com

HP MJF 580

Killed off after only four years in production, HP’s colour 3D printer can still be found hard at work in some service bureaux, and with good reason. The parts it produces, when post-processed, are tougher than the competition and the process is relatively fast. This allows for customised, functional end-use parts (such as prosthetics) to be built and to complement or stylise a product to the individual user’s tastes.

Parts are high density and low porosity PA 12 Nylon, which itself is pretty robust, but is further enhanced by post-processing. The ability to work with colour at the voxel level means smooth gradients and 1,200 dpi crisp details right across the 332 x 190 x 248 mm build area.

A range of post-processing techniques can be applied to get the most from the parts, most of which can be automated, from primary blast cleaning through to vapour smoothing that enhances colours and increases mechanical properties.

www.hp.com

Stratasys J55 Prime

At the other end of Stratasys’ J-Series product line is the J55, a scaled-down, design studio-friendly version of the J850, designed to pop off colour models at will.

Its rotating, circular build platform manages to squeeze in more than expected for a printer of this footprint, while the J55 has been developed to sit alongside designers with minimal noise and odour, and offers simple water-soluble supports.

The wide colour range is still here, as are digital materials such as VeroUltraClearS, which can simulate glass and plastic in a range of colour tints, and Stratasys’ Elastico flexible photopolymer, which in clear or black versions has high elongation to give it breakand tear-resistance.

The only thing that might slow you down if using this machine at full capacity is regularly changing the single litre material cartridges, compared to the 16-litre units found on the J850.

www.stratasys.com

MimakiI 3DUJ-553

The name and appearance of the 3D printer might seem industrial, but that’s squarely the point when you see the 3DUJ operate alongside other products from the Japanese brand.

What the unit forgoes in memorable titles and soft angles, it makes up for in eye-popping 10 million colour output, which thanks to Mimaki’s industrial printing heritage, uses ICC colour profiling for consistent and repeatable results.

The 2D printing heritage shows in smooth colour gradations, as the printer looks to minimise granularity across its 508 x 508 x 305 mm build volume, while Mimaki has also developed a clear resin, allowing full transparency and semi-transparent colour to be realised.

Able to print in 19, 32 or 42μm layers, super-fine text detail and smooth surfaces can be achieved, while water-soluble supports preserve edges and delicate elements.

www.mimaki.com

3D Systems ProJet CJP 660Pro

The grand old dame of colour 3D printing, the ProJet CJP is showing its age. It’s a ZCorp 3D printer with a facelift and some mild upgrades along the way since the company was acquired by 3D Systems over a decade ago.

But as ever, age is just another way of measuring experience, and while nobody will be fooled into thinking parts produced via 4-channel CMYK output that maxes out at 100μm layers is the real thing, it can print full-colour models at a speed of an inch an hour, making it both the fastest and cheapest 3D printer on this list. This frugality also applies to materials, with the base powder comparatively cheap compared to resin. What’s more, unused powder can be reused.

With a build area of 254 x 381 x 203mm and no supports necessary, you can see why these machines continue to run in workshops where ‘quick and dirty’ prototypes from simple OBJ files are needed.

www.3dsystems.com

Dyemansion Dyed SLS, SAF and MJF parts

White Nylon parts, built via SLS or HP’s MJF process, can be post-processed to take on block colours.

A rudimentary colour bath can do the job, but for scale and colour accuracy, you’re best looking at an automated solution like Dyemansion’s DM60 series, which also fits as part of a full post-processing cleanup and finishing set-up with cloud monitoring.

Clean parts go in, and 150 minutes later, colour parts come out. Simple.

www.dyemansion.com

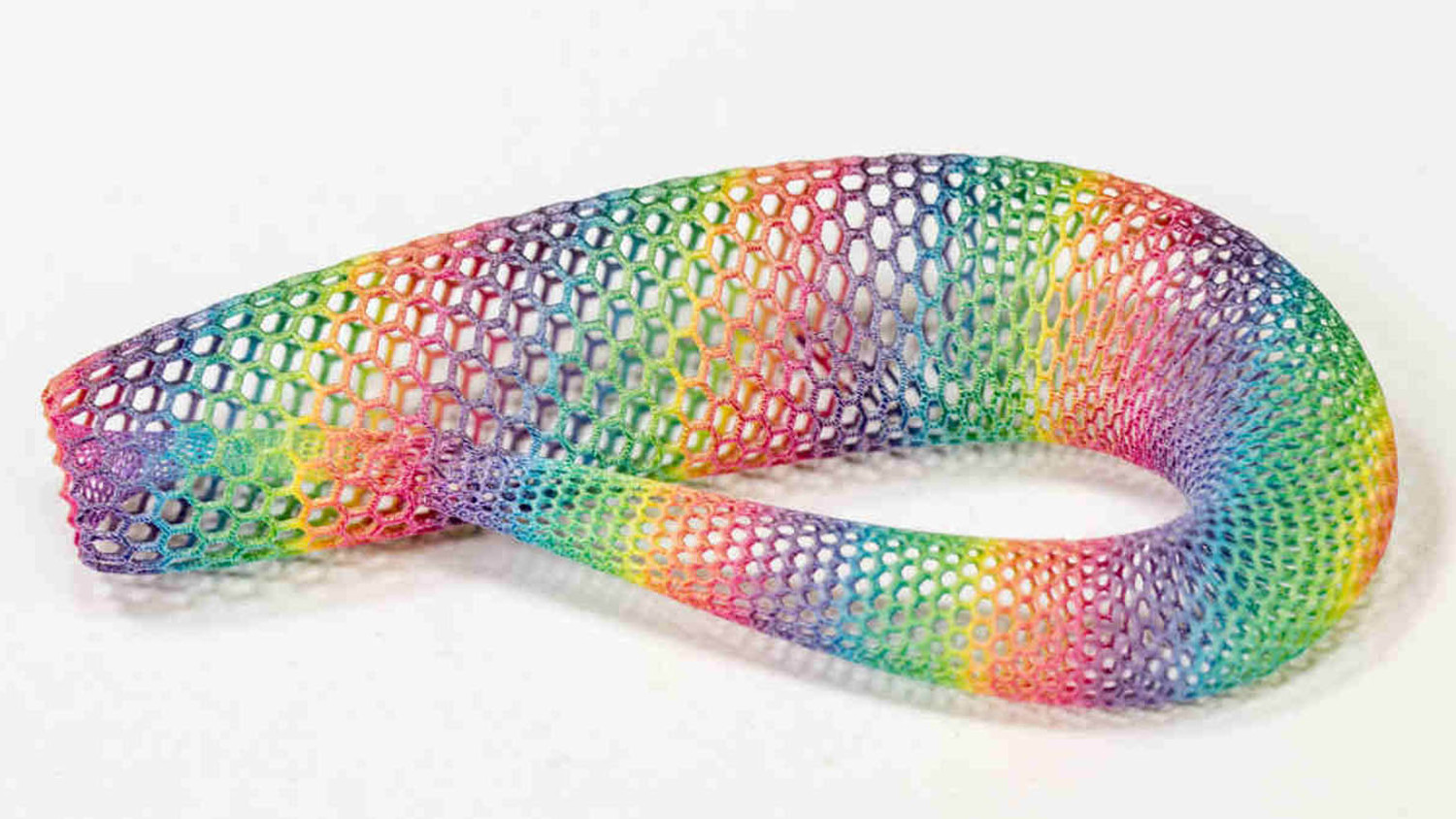

Carbon all M- and L-series

If single-colour, end-use elastomer parts are what you’re about, then Carbon’s recently announced EPU 46 material, which supports direct resin colourisation, should certainly be on your radar.

Users can mix their colours with opaque and transparent variants, creating bold colours in a rainbow of different shades.

With a shore-hardness between 55 and 78, users can also finetune the material stiffness of the elastomer.

www.carbon3d.com