Materialise Magics has also been integrated into CO-AM and offers a new workflow automation feature.

Since launching the CO-AM platform in May 2022, more than ten companies have joined as technology partners. New partners include Trickle, Twilit, Additive Marking, SLM solutions and tools from AMT, DyeMansion and PostProcess.

These new partners aim to automate and track post-processing steps, monitor machine data and enable traceability through automated labelling and authentication technologies.

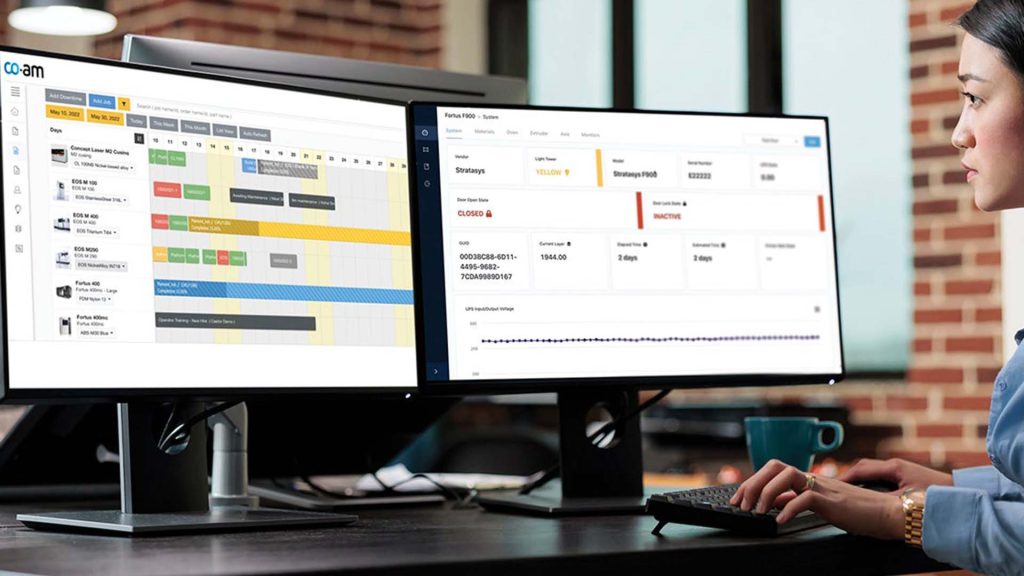

The Materialise CO-AM platform aims to offer a space for innovation and co-development to the AM industry and manufacturing companies, by providing manufacturing companies direct access to multiple hardware technologies and their preferred tools from Materialise and other software developers.

This was designed to allow the CO-AM community to co-develop end-to-end manufacturing solutions that create competitive advantages for individual companies and empower entire industries.

Customers in major manufacturing industries, including aerospace, automotive, consumer, medical, and energy, should have access to the latest AM innovations via the platform and will be able to integrate and connect them seamlessly.

“With these new partnerships, the CO-AM community continues to grow, creating the first end-to-end software platform that offers an open ecosystem for the additive manufacturing industry,” said Materialise CTO Bart van der Schueren.

“Collaboration is key to realising the potential of additive manufacturing and to give our customers seamless access to a full range of software tools to plan, manage, and optimise every step of their 3D printing process.”

“End-to-end connectivity in CO-AM offers significant advantages for our partners and our customers,” said senior director of CO-AM Vishal Singh.

“For our partners, connecting their applications to the CO-AM platform provides them with opportunities to reach new customers more efficiently. Our customers benefit from a unified user experience throughout Materialise and partner solutions.”

Manufacturing companies turn to AM to mass produce identical or customised products, said Materialise, as they are looking for ways to achieve repeatable quality standards and minimise the amount of manual intervention.

With the addition of the seven new partners, Materialise aims to deliver on the promise to connect and automate all steps of the AM process. The CO-AM platform looks to give users the flexibility to build a process that is tailored to their business. A growing number of tools to support each step in the AM workflow enables them to choose their preferred solution.

Materialise has also extended the integration of Magics 26, and its data and built preparation software, into CO-AM. The integration aims to enhance traceability, allowing users to monitor and improve AM processes throughout the workflow, from data preparation through design iterations to the final printed part.

In addition, Magics’ new workflow automation feature should offer off-the-shelf scripts to automate common build preparation workflows and enable customers to use customisable scripts to automate build preparation tasks unique to their AM operations.

“The deep integration and workflow automation feature of Magics in CO-AM creates a digital thread between data and build preparation and the overall AM workflow,” said Egwin Bovyn, Materialise product line manager of Magics 3D print suite. “This is an important step to enable data management across all technologies within CO-AM. It will allow users to reduce production costs and scale AM operations more efficiently.”