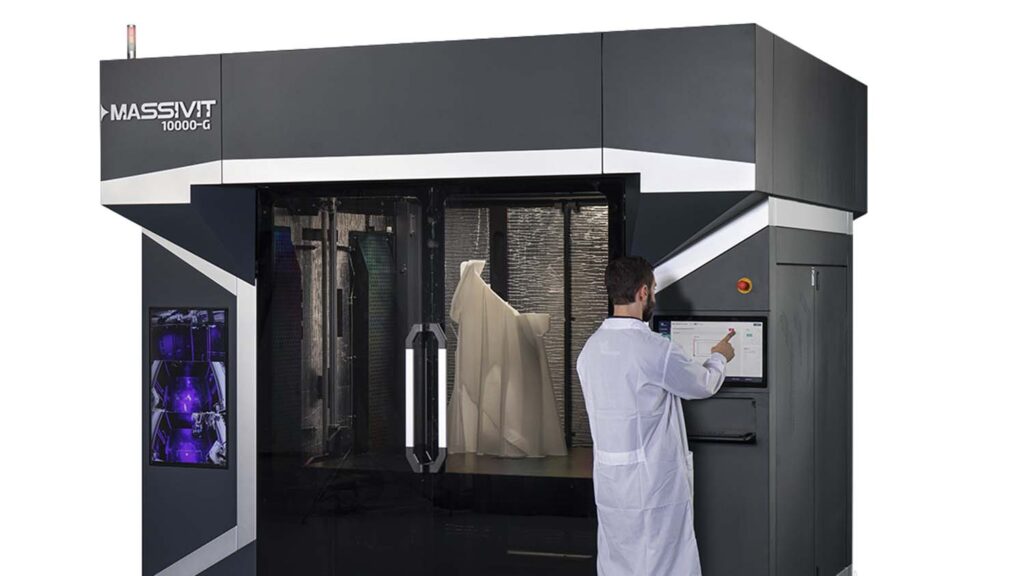

Massivit has announced the introduction of Massivit 10000-G to the European composites market at the JEC World event, taking place from April 25 to 27 at the Paris Nord Villepinte Exhibition Centre.

The event will also mark the launch of Massivit’s 2023 corporate rebranding in line with the company’s latest technological milestones and strategic penetration into the composites arena on its 10th anniversary.

The provider of large-scale additive manufacturing systems said its aim is to automate and speed up workflows for composite manufacturing.

Based on the company’s Cast In Motion technology, the 10000-G should facilitate the digital production of complex moulds, mandrels, master tools, jigs, and fixtures for a range of industries including automotive, rail, marine, defence, consumer goods, and sporting goods.

Cast In Motion technology brought to market the first isotropic 3D-printed mould and has been adopted by customers in various sectors.

At the JEC World event, visitors will have the opportunity to experience live demonstrations of the Massivit 10000-G at Massivit’s Booth K58 in Hall 6, as well as a showcase of industry applications.

The Massivit 10000-G looks to offer significant production time and cost savings, up to 80% of mould production time and 50% in material costs.

This latest industrial 3D printer on the company’s second-generation product line should provide access to Massivit’s full set of Dimengel thermoset materials that have until now been available with the company’s Gel Dispensing Printing (GDP) product line.

GDP enables custom manufacturing and functional prototyping before going into production at up to 30 times the speed of other technologies.

“We are thrilled to introduce the revolutionary 10000-G to the European composites market at JEC World 2023,” said Massivit 3D CEO Erez Zimerman.

“This event is the perfect platform to showcase our latest innovations and connect with industry leaders and experts. We are confident that our 10000-G printer will disrupt composite materials manufacturing as we know it, and we can’t wait to share it with the world.”

Massivit said its corporate rebranding represents a significant step forward for the company, reflecting its strategic endeavours to overcome real-world manufacturing needs by offering new, advanced additive manufacturing technologies.

Massivit’s vision is to transform large-scale manufacturing from traditional processes to digital, high-speed production using industrial-grade materials, while innovating, sharing knowledge with the global manufacturing and additive manufacturing communities, and supporting greener manufacturing through waste-free, additive innovation.