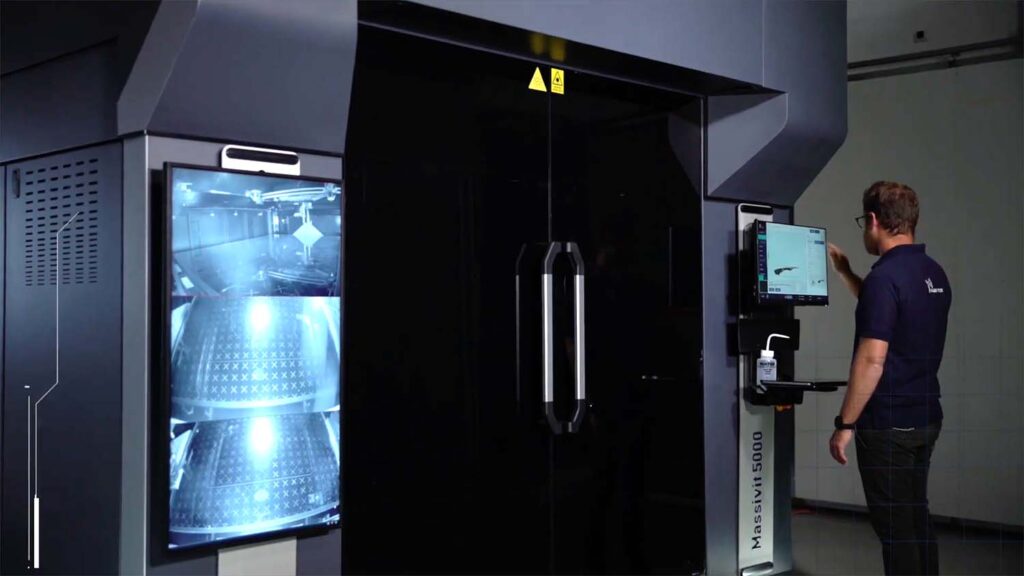

Massivit 3D, already known for its large volume Massivit 1800Pro 3D printer used in one-off film props and 3D advertising boards, has launched the Massivit 5000, for polymer parts up to 1.45 x 1.11 x 1.8m (that’s ‘m’ for metres!) in size.

Based on the company’s patented Gel Dispensing Printing (GDP) technology, the new Massivit 5000 adds higher resolutions, materials, and automation capabilities.

A new printing material, Dimengel 110 is said to facilitate high-definition printing and greater fidelity to CAD designs.

Two new resolutions enable print optimisation according to layer thickness and speed requirements.

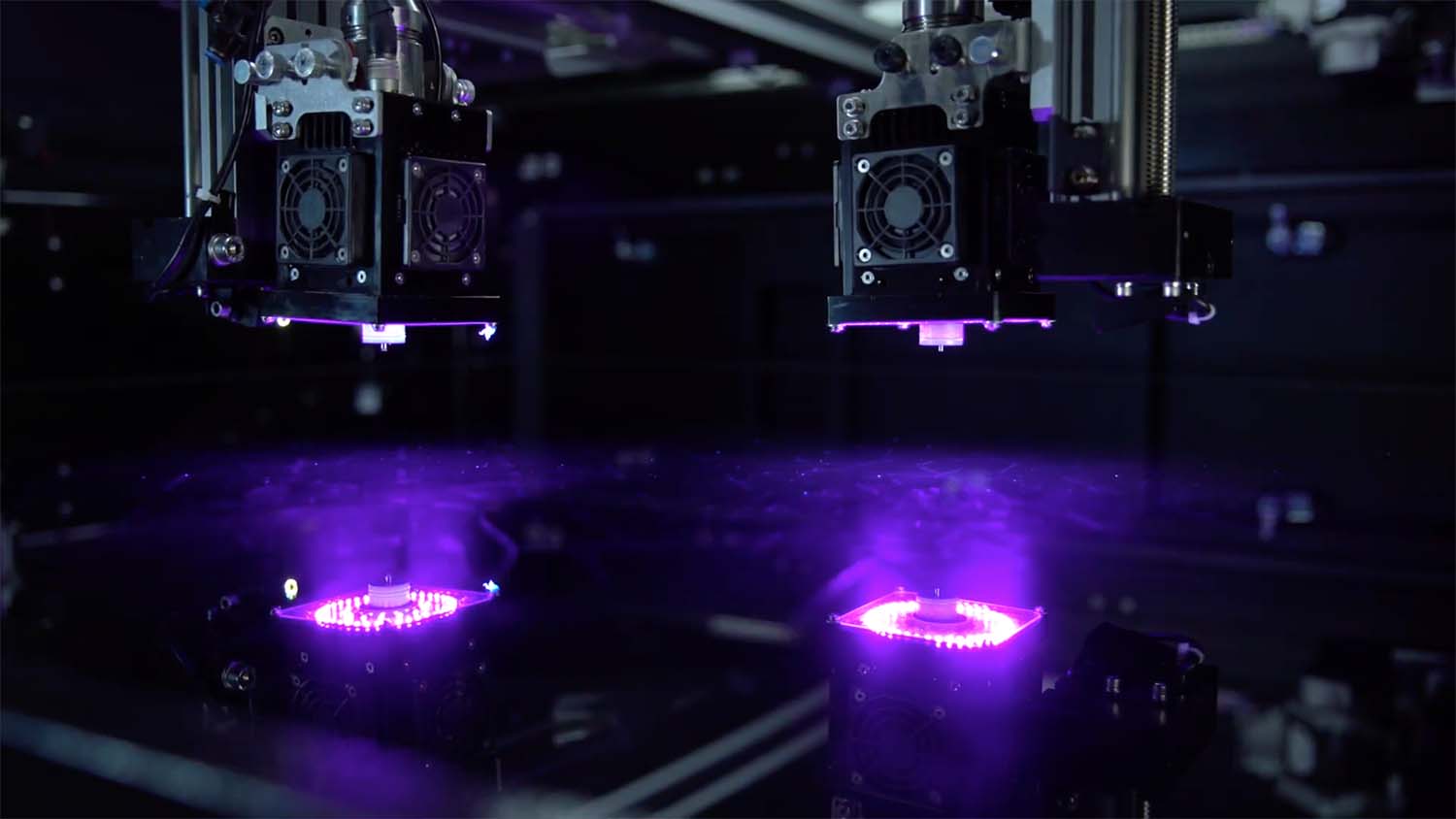

The Massivit 5000 offers a Dual Material System that allows operators to print simultaneously with a different material on each head, with the gel cured as it lays.

New software automation features have been added, that aim to allow operators to improve workflow efficiencies and enable easy monitoring and operations.

It is hoped that the new Massivit 5000 will help the company find a wider audience in further large-scale 3D printing uses for automotive, marine, and rail.

Massivit 3D CEO Erez Zimerman, said: “We are thrilled to bring to market this new additive manufacturing system that will empower manufacturers to overcome existing limitations in production speed, size, and complexity.

“It is a significant milestone on our roadmap towards transforming manufacturing of large parts across multiple industries.”

Founded in 2013 by a team of 3D printing and 2D printing experts, Massivit 3D is headquartered in Lod, Israel and successfully completed its initial public offering (IPO) on the Tel Aviv Stock Exchange (TASE) in earlier this year.