Holo has launched PureForm MicroAM for high volume parts in with features less than 50μm in copper, stainless steels and other metals.

Earlier this year Holo launched PureForm for the production of high-performance pure copper parts directly for customers using its proprietary high-resolution, high-throughput technology.

PureForm MicroAM is ramping up at Holo’s 20,000-sq foot production facility in the San Francisco Bay Area, where it has capacity to produce tens of thousands of parts per month for applications including electrical components, jewellery, and medical and dental devices.

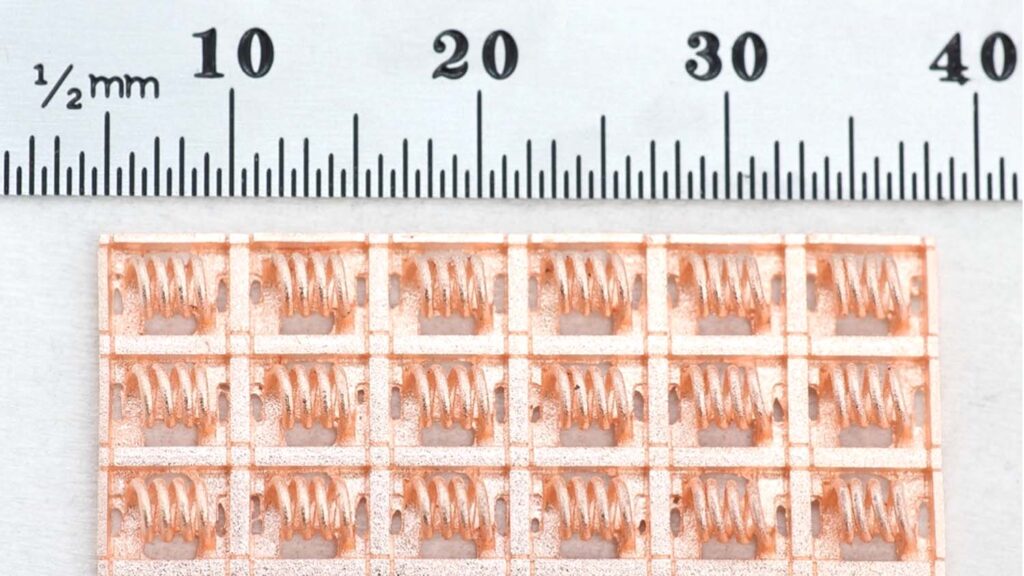

The technology has already unlocked capabilities for beta customers in the electronics industry, producing fine featured micro inductors coils built with 400µm strands, and in high-end custom jewellery.

“Traditional manufacturing approaches, such as Swiss CNC, molding and casting are either too costly for volume production or cannot produce complex parts with such fine features,” said Holo CEO Hal Zarem.

“PureForm MicroAM enables our customers to access parts at a lower cost and produce geometries that cannot be made any other way.”

Other AM applications that have been enabled by the additive process include stainless steel biopsy scoops used in medical applications with sharp point features, down to 20µm and dental abutments with printed functional threads that hold a 200µm pitch.

“We are excited to continue to offer new capabilities to our customers, enabling us to support a host of new MicroAM applications from surgical equipment and dental, to micro-electronics, micro-robotics, consumer electronics and jewellery,” said Arian Aghababaie, Holo co-founder and chief strategy officer.