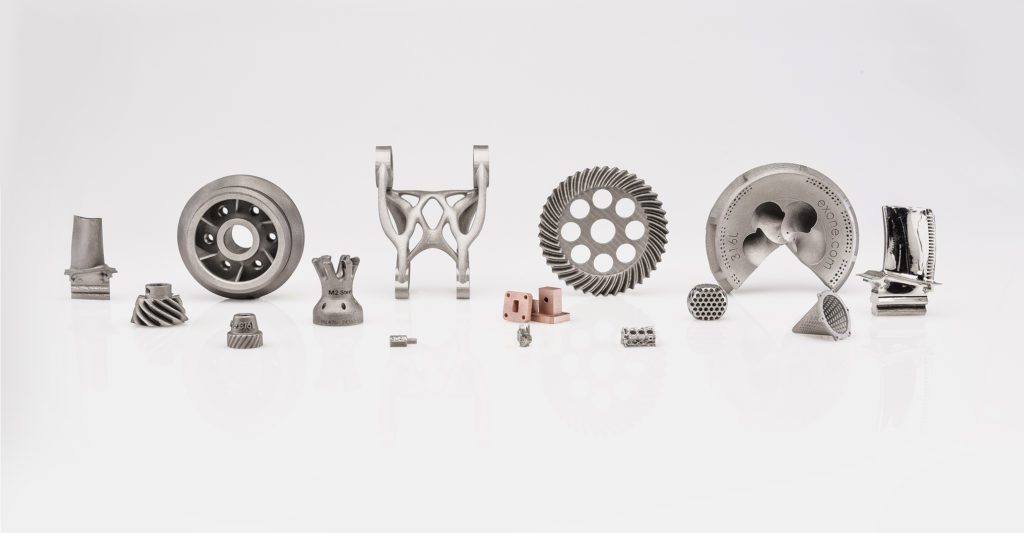

ExOne has announced that it’s batch of newly qualified materials for binder jetting takes its total to 21, including 10 single-alloy metals, six ceramics, and five composite materials.

Top of the class are M2 Tool Steel, Silicon carbide, Aluminium and Inconel 718 – all with serious functional properties.

“ExOne continues to make aggressive and outstanding progress in qualifying new materials for 3D printing on our machines,” said ExOne CEO John Hartner. “Qualifying a new material for binder jet 3D printing is complex work that involves optimising how materials, machines and processes work together.

“We would like to thank our customers and partners for their assistance in accelerating this important work, which is enabling more sustainable manufacturing and part designs.”

ExOne believes the ability to 3D print some materials at high speeds, such as aluminum, will have a transformative, sustainable effect on the automobile and aerospace industry.

“While our teams can binder jet aluminum in controlled R&D environments today, we believe that optimising this material for high-speed 3D printing will eventually transform how car and airplane parts are made, making them smarter and lighter weight,” said ExOne CTO Rick Lucas.

“Based on high demand from the marketplace, we have fast-tracked development of this material for use on our machines.”

A further 26 materials have passed a preliminary qualification phase by ExOne – including H11 tool steel, tungsten and boron carbide – and are deemed printable, supported by ongoing development.

Late last year, ExOne announced its new X1 160PRO metals printer to target high volume production.