The Epsilon Series has received its first major update since BCN3D launched the 3D printer in 2020, with the new features proving a productivity boost for the bench top machine.

A new heated ventilation system lowers internal pressure and lets the interior absorb air from the outside while new Trinamic TMC2226 motors drive the machine quietly and with greater efficiency and better engine torque while staying cool.

The new generation sees a custom-made signal board for the Epsilon. Specially designed for BCN3D products, it concentrates the main features into one single board, as opposed to being formed of several commercial pieces implemented in various areas of the printer, for a simpler and in turn more efficient main board.

Newly added local network access now means files can be sent to the printer remotely, and jobs monitored, paused and canceled.

However, it’s the new Autocalibration XYZ, billed by BCN3D as “the fastest one on the market” that leads the technical updates. At the push of a button, the automatic process is said to be capable of reducing print set-up time ‘from 40 minutes to just six’ in a foolproof manner.

The calibration process is done by measuring multiple points to automatically adjust the printing surface height and (XY) offset between both nozzles, which for BCN3D’s Independent Dual Extrusion System (IDEX) had to take the XY alignment of the two toolheads into account.

This is done through the use of a square located at the back of the printing surface. The toolheads use this small opening to touch the sides with the hotends, calculate their positioning on both the left and right axes, and subsequently calibrate the right offsets between them. This XY alignment ensures they are perfectly aligned and avoids any crossovers or shifting layers when printing in dual mode.

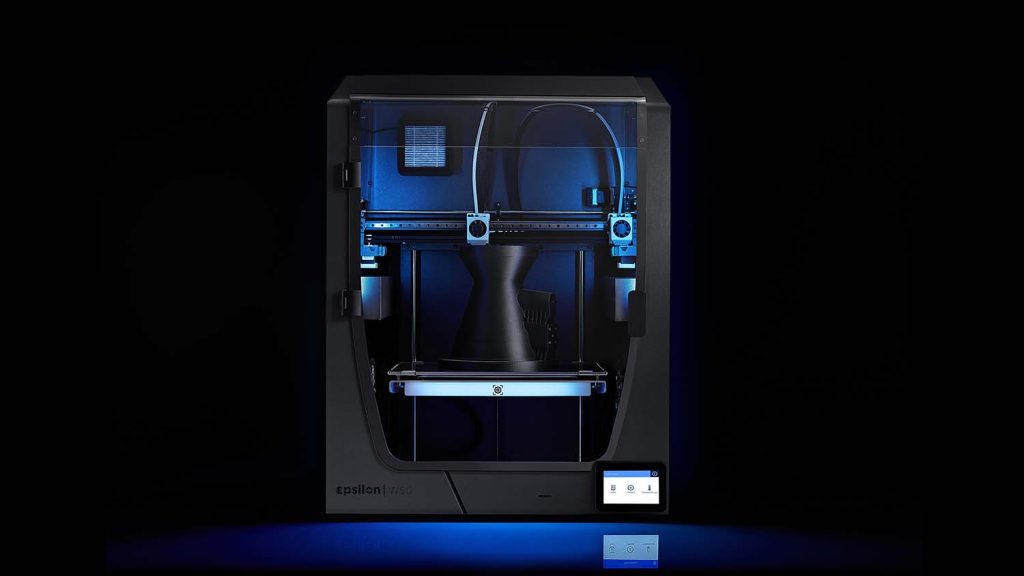

The updated generation, which includes the W50, W27, W50 SC and W27 SC are available to purchase now.