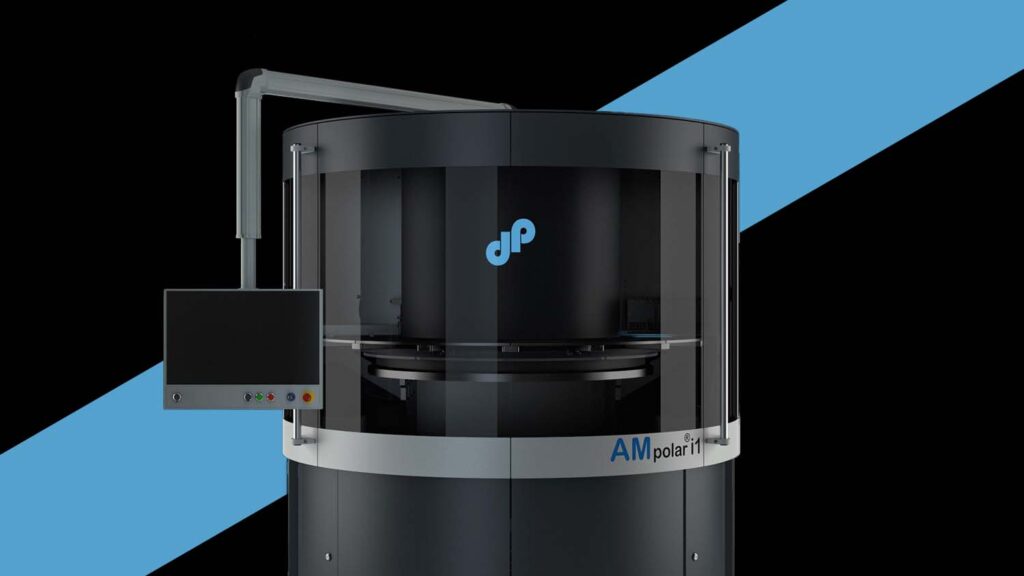

DP Polar, a German manufacturer of additive manufacturing systems designed for autonomous production, has announced its AMpolar i1 3D printer for scaled production.

The AMpolar i1 harnesses DP Polar’s single-pass printing process, which relies on a rotating circular build platform and multiple removable trays that can be autonomously removed by robot.

DP Polar says the technology will enable build volumes of ‘up to 240 litres’ across its innovative print platform, which has a build area of just under one square meter.

Layers of between 4-25µm can be put down using Xaar 1003 printheads that give it the capacity to jet a variety of fluids at increasingly high viscosities – up to 100 centipoises (cP) – in a single pass, opening access to an exciting range of new applications.

DP Polar MD Florian Loebermann, said: “The AMpolar i1 delivers all the production benefits of the AMpolar i2, but at a scale and in a format that facilitates businesses in their early stages of exploring what is possible in mass production 3D printing.

“Xaar’s printheads have proved invaluable in unlocking the full potential of our systems, and the openness of the Xaar team to support our innovations is helping to establish 3D printing and Additive Mass Manufacturing as a practical reality in the volume production of parts for many industries.”

Gareth Neal, Xaar’s customer applications manager, Advanced Applications, Technologies & Fluids, added: “The innovative and agile AMpolar i1, firmly establishes the use of resin jetting as a truly practical and commercially viable manufacturing process.

“With Xaar’s range of printheads including our unique Ultra High Viscosity Technology providing the speed, flexibility and reliability demanded, functional inkjet applications have never been more accessible, affordable or productive.”

The usage of the Xaar 3D printhead is another significant use of Xaar 3D technology, following the use of Xaar 3D’s powder-based SAF technology in Stratasys’ H350 3D printer.