The world’s first 3D printed ceramic car engine piston has been developed by Spyros Panopoulos Automotive (SPA) for its revolutionary Chaos Ultracar using XJet technology.

The Chaos Ultracar has hit the headlines as a 3,000hp rocket masquerading as a $14M road car, that claims a 0-62mph time quicker than it takes to read the numbers on the page (1.55 seconds!).

Spyros Panopoulos is pursuing speeds of over 500kph with the design. Consequently, it has the fastest-revving production car engine ever seen, reaching up to 12,200 RPM and an astonishing 3,065 horsepower.

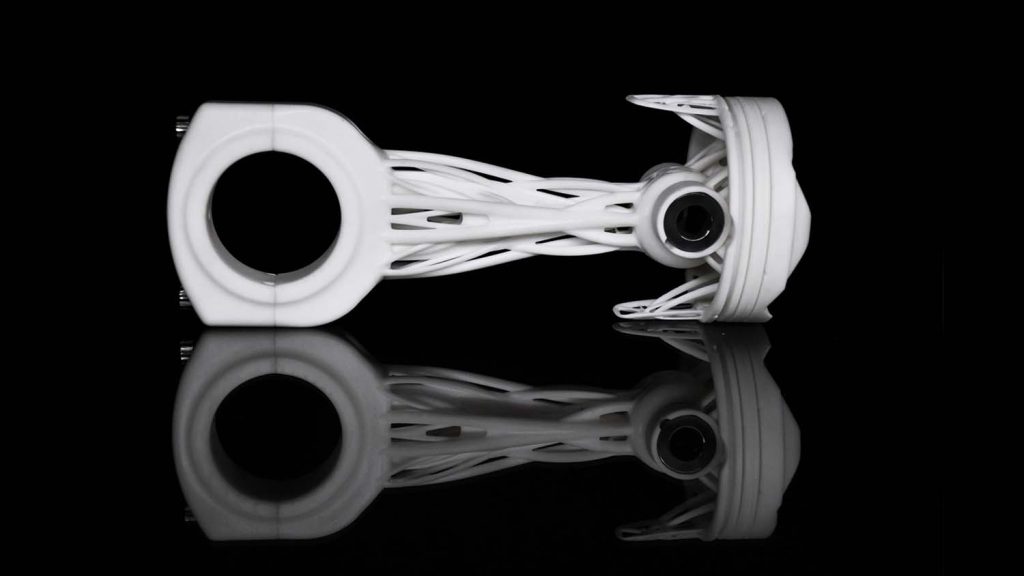

To support the extreme levels of performance required, the engine piston was designed using what Panopoulos describes as his own proprietary method of topology optimisation, ‘anadiaplasi’, where material is minimised where it doesn’t support performance and added where reinforcement is needed, optimising weight while maintaining the strength and temperature resistance of the part.

The resulting complex organic shapes are implemented throughout the Chaos Ultracar.

On concluding the design, Panopolous worked in collaboration with Lino 3D, XJet’s business partners in Greece, using XJet Alumina material for the Chaos piston due to its strength, hardness, light weight, and almost total resistance to thermal expansion, which made it the perfect material for the task.

“Ceramic offers many advantages compared to other materials,” Panopolous comments. “Harder and stiffer than steel, more resistant to heat and corrosion than metals or polymers and weighing significantly less than most metals and alloys.

“XJet’s alumina parts will withstand the high temperatures expected to develop within the combustion chamber as well as on the fast-moving parts… There’s absolutely no room for error in this project.”

An advocate of additive manufacturing, Panopolous is putting it to use throughout the Chaos Ultracar with a reported 78 per cent of the body being 3D printed as well as other crucial elements such as the engine block, camshaft and intake valves.

“We are proud to be using such progressive technology in our Ultracar,” asserts Panopolous, “Our projects push performance to the extreme and so we are extremely selective about the materials and technologies we use. I believe this is the first-time ceramic AM is being used in motorsport and I feel privileged to take that pioneering step.”

XJet VP strategic marketing Haim Levi, said: “SPA is taking ceramic additive manufacturing and design for AM to the edge and beyond with their work on the Chaos Ultracar.

“We’re extremely proud to be part of such a trailblazing project by offering the top-level capabilities of our technology and system. Designers and engineers from a wide range of industries and applications are exposed to new options now opened for them. We expect the Chaos project ceramic piston to ignite their creativity and imaginations and push the limits in the automotive industry and beyond.”