Airbus has qualified Materialise and EOS as the first to supply its aircraft with new SLA parts 3D printed from flame retardant polymers.

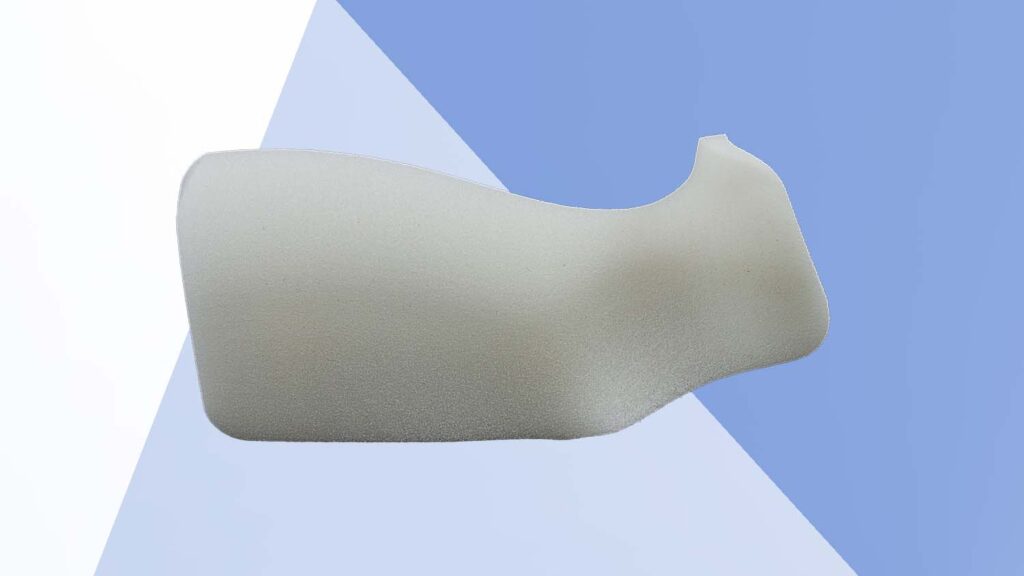

Typical aerospace applications include aircraft interior parts such as air ducts and brackets, which using 3D printing can even be customised for each customer airline.

The material, EOS PA 2241 FR, is suitable for parts needing to fulfil fire, smoke and toxicity (FST) requirements, without use of a primer and top coating.

Due to the powder’s high refresh rate, EOS states that the PA 2241 FR can enable cost-effective production while meeting the strict quality standards required of flight-ready parts – in this case, Airbus Process Specification AIPS 03-07-022.

Belgian 3D Printing veterans Materialise currently print around 100 different part numbers for the Airbus A350, totaling an estimated 26,000 parts per year across the A350 ecosystem.

Additionally, the company is also set to supply parts for other Airbus aircraft platforms – including the A320, A330, and A340 – with EOS 3D printing technology playing a key role.

Materialise CTO Bart Van der Schueren, commented: “This achievement consolidates our long-term partnership with Airbus, and it also opens up additional 3D printing applications to Airbus and its suppliers.

“Laser sintering is one of the most widely used 3D printing technologies and enables complex design features such as interlocking mechanisms. It’s an honour for Materialise to be Airbus’s first manufacturer for the technology.”

The qualification is an important milestone in the deployment of Polymer AM technologies in Airbus, which Materialise began its journey several years ago when FDM technology was introduced on the A350 system.

This new capability is hoped will enable an increase of applications on commercial aircraft and, as well, on the products developed by the other Airbus Divisions.

EOS EMEA senior VP Markus Glasser, said: “We are very proud that after an extensive testing program, Airbus qualified the EOS PA 2241 FR material and processes for usage globally by the company.

“It underlines the high maturity and constant quality of EOS’ powder and systems and continues to emphasise the relevance of industrial 3D printing in both polymers and metals.”

Airbus has been at the forefront of 3D printing adopting in aerospace – find more stories about its use cases and applications here.