3D Systems has launched Accura AMX Rigid Black, labelling the new tough stereolithography material as a ‘breakthrough production-grade’ acrylate resin.

Designed for use with the company’s SLA technology, it is the first from 3D Systems for the production of large-scale additively manufactured parts with high resolution, accuracy, and surface quality capable of withstanding the rigours of long-term mechanical use.

Accura AMX Rigid Black is 3D Systems’ latest customer-centric innovation – inspired in part by the advanced production application requirements of Toyota Gazoo Racing (TGR).

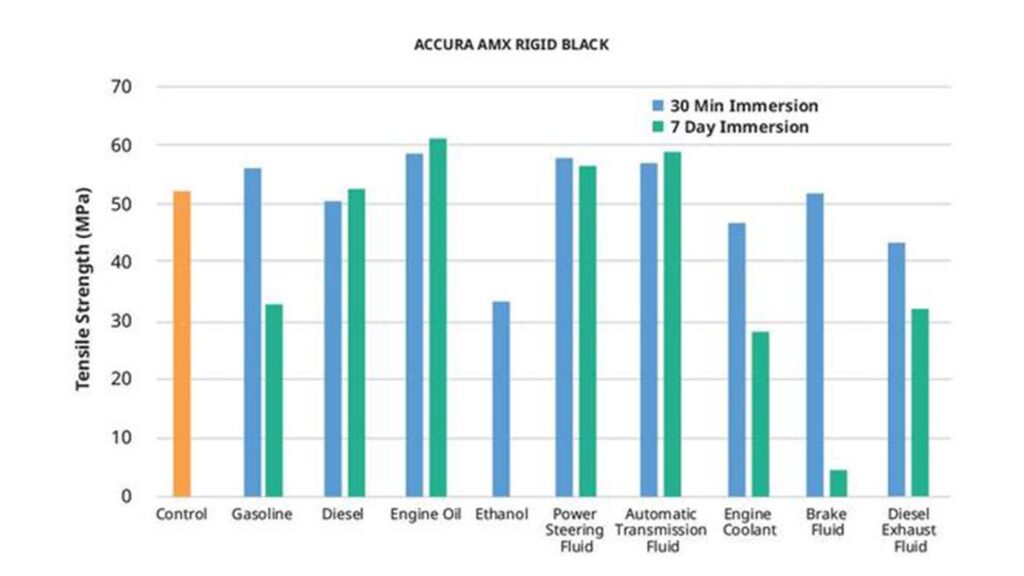

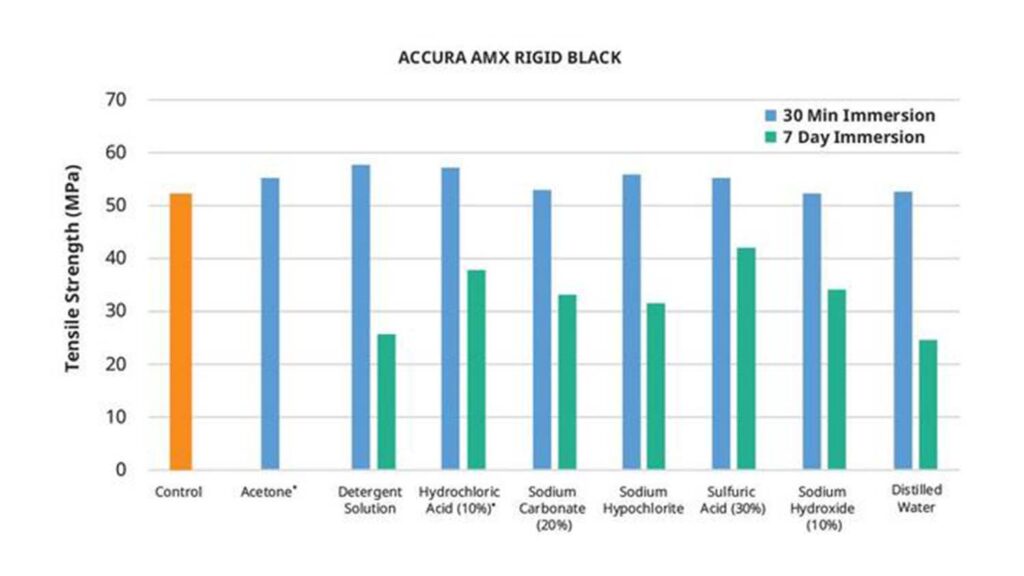

As a result, the material has been developed with automotive chemical and application compatibility in mind, with Accura AMX Rigid Black parts tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. The full data sheet includes additional data tables for tensile modulus, notched impact strength and elongation at break.

In 2019, 3D Systems entered a partnership with TGR to develop manufacturing solutions to revolutionise automotive design and production. TGR has extensive experience with 3D Systems’ Figure 4 system and materials, yet had a vision for a CNC fixture that would be larger than the build size of the Figure 4 3D printer.

“Accura AMX Rigid Black allows us to deliver larger, complex SLA production parts, including full-scale manufacturing aids,” said Alexander Liebold, group leader, production engineering and future technologies, TGR.

“We recently used the material to develop 3D printed fixtures for stabilising larger automotive components for CNC milling. Using Accura AMX Rigid Black we achieved 90% time savings and 60% cost savings in comparison to the previous handwork process for a batch of 40 parts.”

Liebold added that the Accura AMX Rigid Black parts provide TGR with smooth sidewalls and superior isotropic strength, critical for its jigs and fixtures that are in constant use.

“Now we can turn around any large-scale part and be confident it will perform as required, for as long as we need. This is a real game-changer for production manufacturing.”

3D Systems says that Accura AMX Rigid Black has been engineered to enable long-term use production parts for a range of verticals, including direct digital production to replace injection moulding or soft tooling processes, as well as manufacturing aids and jigs and fixtures.

“As part of our strategy to invest in and continue to add innovative products to our SLA material portfolio, the introduction of Accura AMX Rigid Black is poised to address a variety of new production applications with additive manufacturing,” said Dr. Edwin Hortelano, senior VP materials engineering and development, 3D Systems.

“For example, we are seeing a larger percentage of work that service bureaus are undertaking is focused on the manufacture of end-use parts. Accura AMX Rigid Black in combination with our SLA 3D printing technology will allow service bureaus to more efficiently, and cost-effectively meet their customers’ needs – helping to fuel the growth of their businesses and their customers’ innovation.

“This is just the first of many planned breakthrough additions to 3D Systems’ portfolio of production-grade industrial SLA resins.”