Nozzle has put 3D scanning and 3D printing to work in its mission to deliver seating tailored to the needs, preferences and proportions of every customer, providing them with optimum ergonomic support, as Emilie Eisenberg reports

Before Aline Ollevier founded Nozzle, she was an occupational therapist working in a rehabilitation department. Firsthand, she witnessed the multitude of issues that sitting in a generic office chair can trigger: back, neck and shoulder pain, muscle stiffness and poor circulation. This inspired the creation of Nozzle and its Up chair, a custom ergonomic office chair.

The customisation of the Up chair begins with the Nozzle App, which uses 3D scanning technology to give Nozzle information about the customer’s posture, measurements and preferences. After a full 3D scan has been conducted, the 3D model is automatically cleaned and processed to create the most ergonomic design possible.

With the information captured by the app, Nozzle then begins the manufacturing process. This starts with designing each chair in Autodesk Fusion, adapting the design to both the customer’s preferences and their workspace requirements. The company then uses Simplify3D to convert the design into a printable file with the most efficient material usage possible.

Get printing

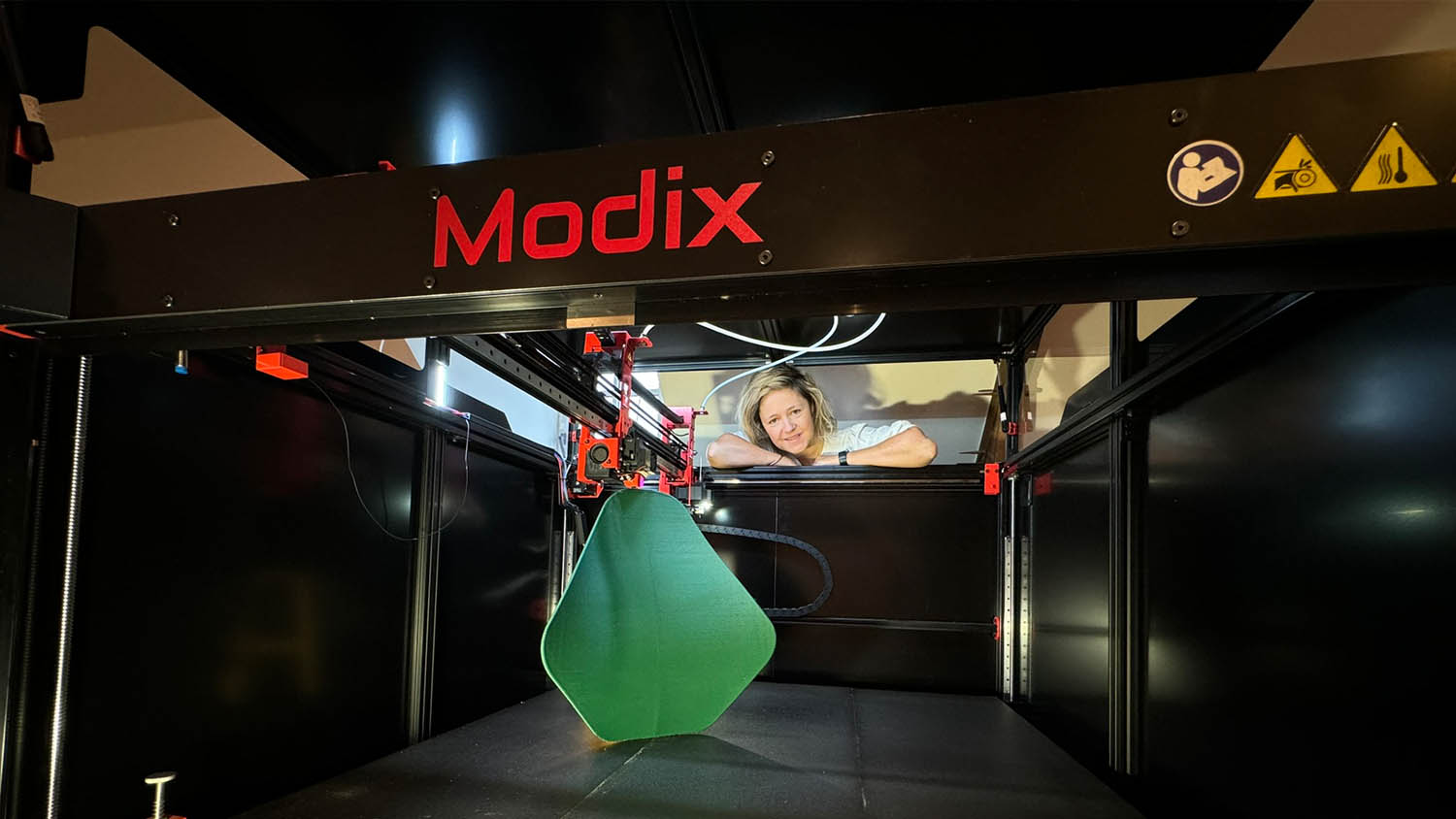

Nozzle uses Modix 3D printers for the manufacturing of the Up chair as a result of its collaboration with OMD3D, a Belgian reseller of Modix printers. OMD3D assists the Nozzle team with technical drawings, strength calculations and technical support.

The seat shell and backrest are printed with upcycled rPP made from old fishing nets, while armrests are printed from biodegradable composite materials. Connection elements and structural supports are also custom-printed. Nozzle sources its recycled materials from Reflow, an Amsterdam-based provider of sustainable 3D printing materials.

The seat cushions are handmade by Studio KUIT in Bruges using sustainable materials, and the chair base is manufactured from recyclable materials. It was important for Nozzle to choose materials that are both sustainable and durable, so that a chair can withstand years of consistent use, says Ollevier.

Once a chair is complete, it can be shipped to anywhere in the world, either directly to a customer or to a reseller. Thanks to this smart application of Ollevier’s rehabilitation expertise, the chair is intended to reduce a user’s muscle pain and stiffness and make sitting at their desk for long periods a less physically uncomfortable process.

Nozzle plans to expand its product line in 2025 with the release of the Flex Desk Chair, a chair designed specifically for shared desk environments; and the High-Mobility Chair, designed for dynamic office set-ups with wheels and increased mobility. The company is also working on a range of 3D-printed ergonomic office accessories, including laptop stands, back support cushions and foot rests, all to be made from upcycled materials.

Nozzle’s goal is two-fold: to reduce the epidemic of back pain and health issues that come as a result of desk working, and to minimise the impact on the planet. The Up chair achieves both, comfortably.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here