IMDEA Materials and Hexagon have announced the first commercially available software, 10X ICME, for Integrated Computational Materials Engineering (ICME) metal microstructure models.

Hexagon’s multi-physics simulation division E-Xstream has developed the partnership under its 10X ICME solution, which will help manufacturers design additive manufacturing processes to improve the properties and quality of 3D printed metal parts.

Spanning across simulation disciplines, E-Xstream says 10X ICME goes one step further in helping to tackle the challenges OEMs face in producing the ‘perfect’ part, whether that be time, cost or availability of data.

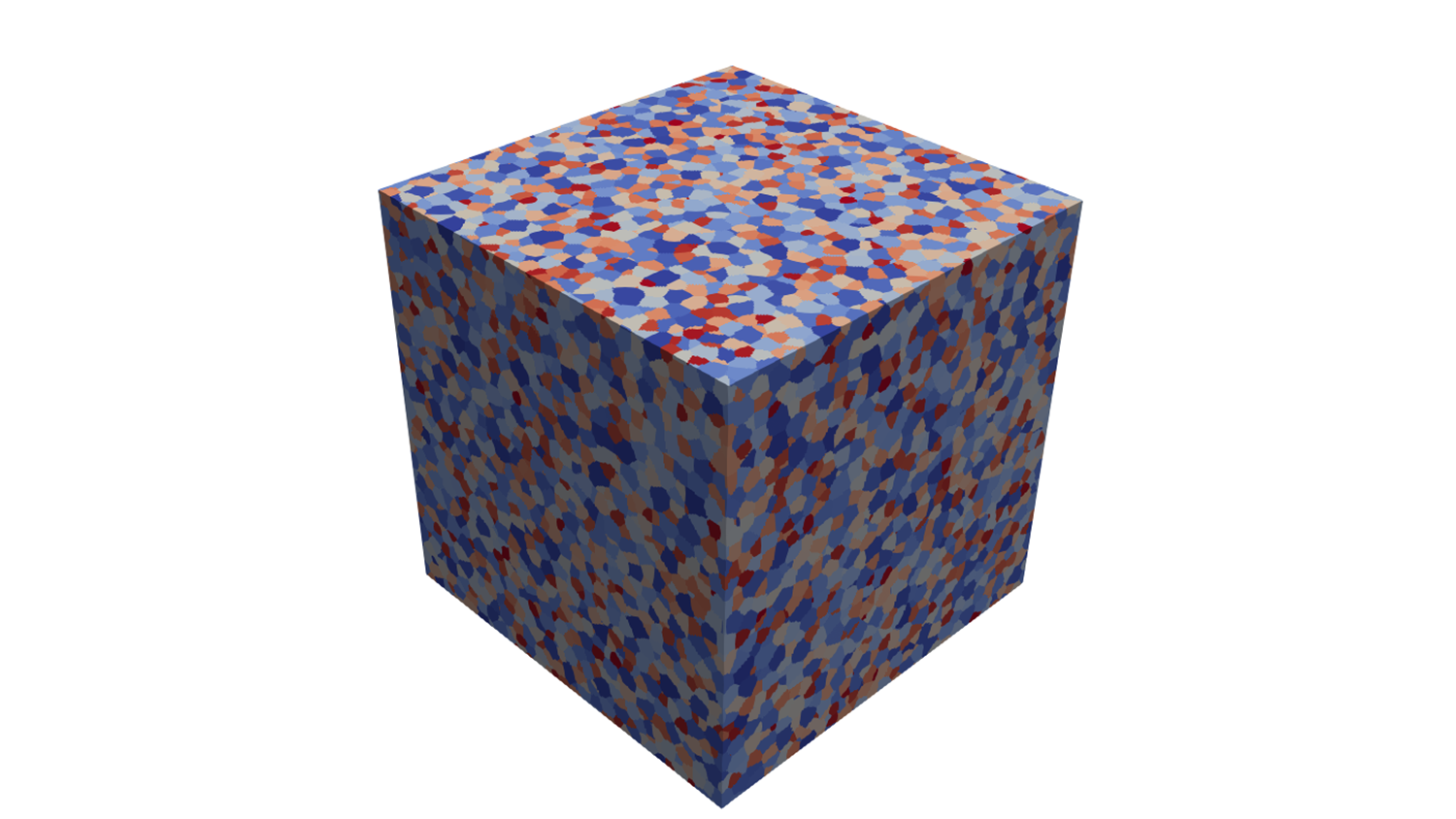

Its insight into the modelling of basic alloys’ elasto-plastic behaviour at the crystal level should contribute to metal ICME by improving the Digimat multi-scale modelling that underpins the 10X ICME solution.

“10X ICME looks to blur the boundaries between materials engineering, design and manufacturing processes, optimising components through the integration of manufacturing, materials and performance prediction,” says a release from E-Xstream.

Madrid-based institute IMDEA Materials will contribute its expertise to improve the accuracy and scope of ICME in modelling metals’ microstructure – a largely unexplored area for commercial manufacturing until now.

Despite the maturity of metal engineering, most manufacturers do not currently take the material’s microstructure into account when building parts, which can severely impact how the part behaves and withstands stress.

With more accurate models, OEMs can potentially improve the quality of their metal components, reduce waste and devise more efficient, connected design and engineering workflows – all while performing the bulk of R&D in simulation to reduce the amount of prototyping and physical testing required.

Optimising parts through more effective use of the source material should also help metal suppliers compete with newer materials such as composites and ceramics.

E-Xstream CEO of engineering Roger Assaker, said: “The breadth and depth of the Hexagon 10X ICME solution is what will help it revolutionise the manufacturing industry.

“Today, it’s driven by polymer-based composites, but with the help of partners like IMDEA Materials – a true pioneer in the field – we intend to apply the benefits of ICME to improve design and innovation using any material that has under-exploited properties and can help manufacturers make better products.”

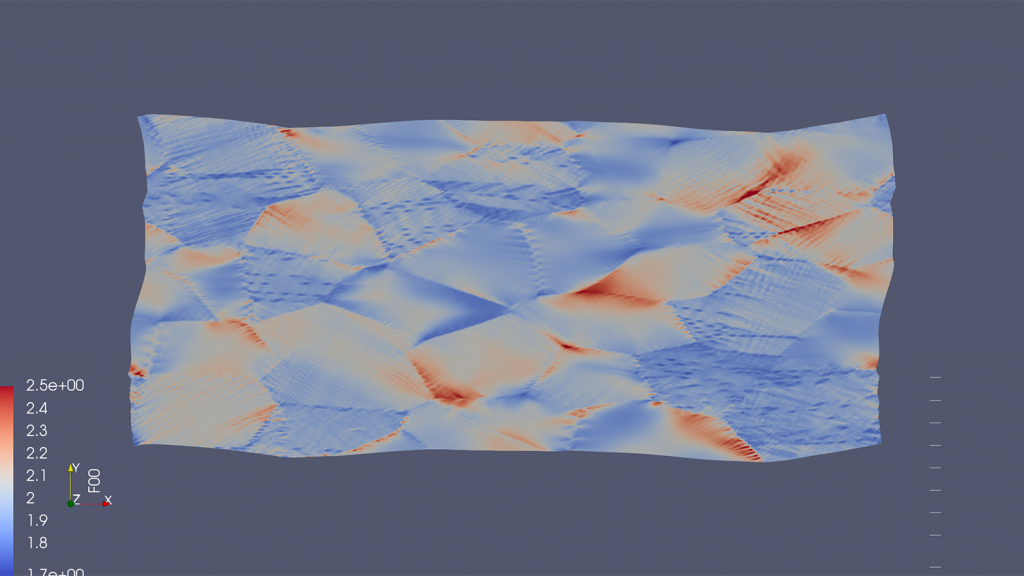

Forming and shaping metal parts produces a variety of microstructures across the component, characterised by the grain size, shape and orientation.

The integration of IMDEA Materials’ models into the 10X ICME ecosystem should equip users with the power to understand why those structures form, and how they will affect the final part’s performance.

This intelligence can then be applied to enrich the solution’s integrated design, engineering and testing capabilities and help manufacturers make informed choices early in the product’s development – for example designing 3D print processes to improve the metal’s properties.

“Until now, ICME has largely been an academic exercise,” said IMDEA Materials Institute director Ignacio Romero.

“One of IMDEA’s pillars is to collaborate with industry, sharing our knowledge of advanced materials to increase competitiveness and maintain technological leadership, so we are delighted for our results to contribute to the first industrialised ICME solution – an approach our research has shown has great potential to further the manufacturing industry as a whole.”

“Our researchers’ expertise covers a wide range of simulation techniques at different scales, from the atomic level to the continuum, and is supported by high performance computing capabilities as well as state-of-the-art laboratories for microscopic characterisation and in-situ mechanical testing.

“We are looking forward to the results of our, Hexagon and E-Xstream’s combined competences.”