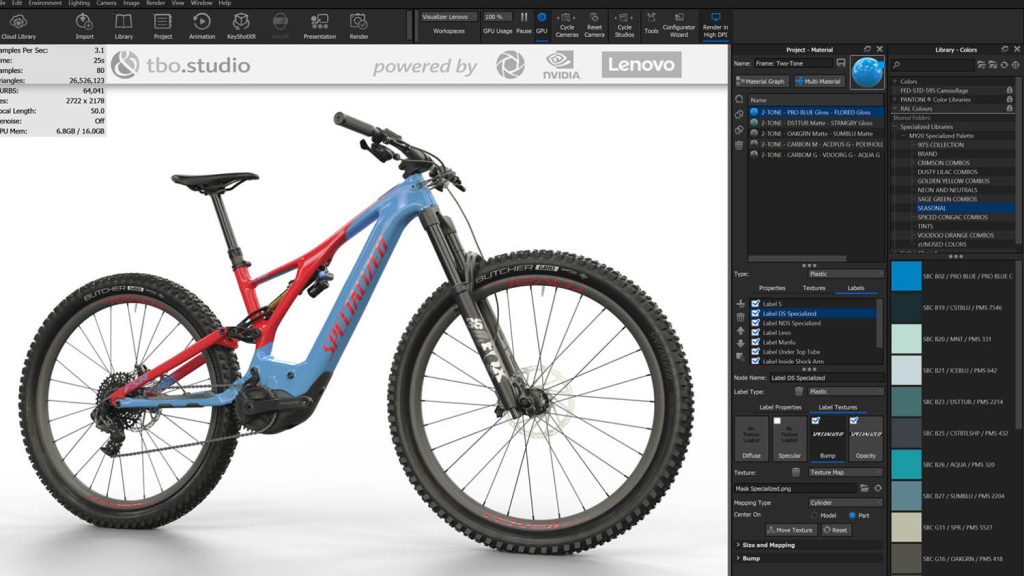

With a slick new workflow for quickly applying 2D decals and colourways onto 3D KeyShot renders, Thomas Burke & Others (TB&O) looked to make Nvidia RTX technology more accessible to its team via a Lenovo ThinkPad P1 mobile workstation

It begins with the Design Visualizer, a 2D-to-3D workflow developed in-house at product imaging studio Thomas Burke & Others (TB&O), with the help of the designers at Specialized Bicycle.

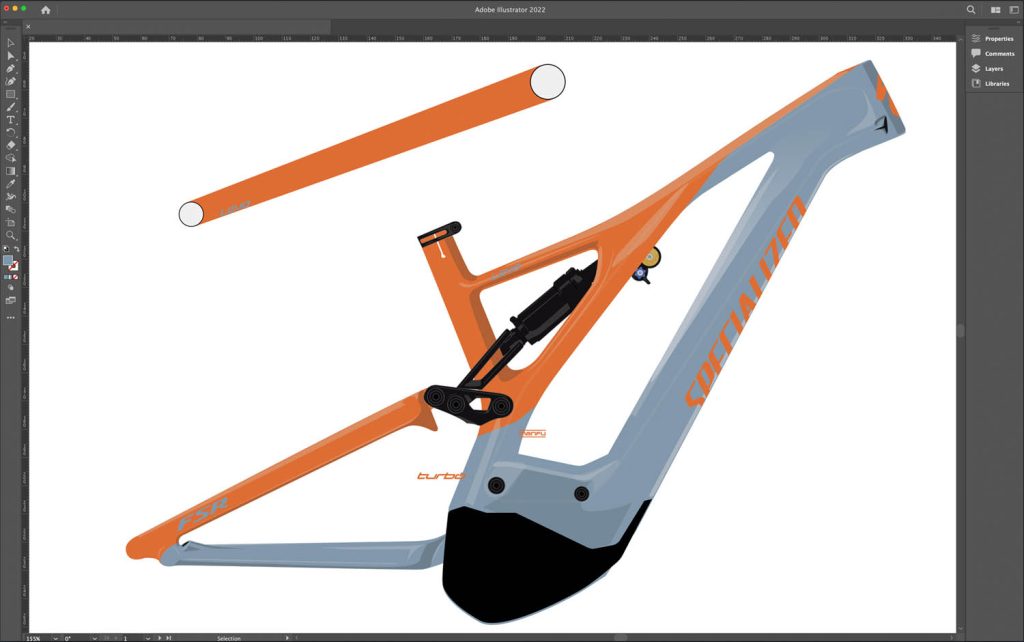

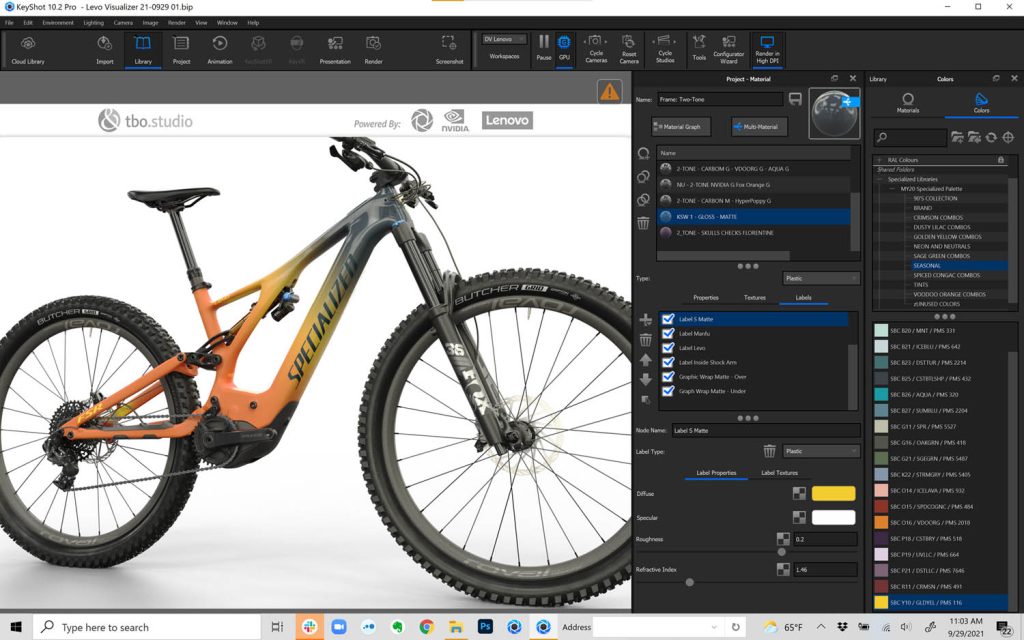

The process allows the teams to toggle between 2D design applications like Adobe Illustrator and realtime 3D visualisation in KeyShot. Designers working on colourways, graphics, and picking material finishes were doing most of their work in a 2D programme like Illustrator – an ecosystem they know and are most comfortable with.

Trying to create stunning product finishes in 2D software without the ability to visualise it in 3D can prove a risk, until a finished sample comes back from the factory, which could be weeks or months down the road.

“We knew one thing,” says Thomas Burke & Others managing principal Mike James. “If we could build a bridge between Illustrator and KeyShot and we could get high-resolution, real-time renders to be real-time, then a designer could jump back and forth between 2D and 3D to dial in their design.”

He continues: “They could see how their design interacts with the lines of the product and, they could see how light behaves as they move their product around in a 3D space.”

On top of this, designers would be free to run more ‘what-if’ scenarios, discover a wider array of product variations, allowing them to be even more creative.

When GPU rendering became available in KeyShot, Thomas Burke & Others started using the Nvidia RTX series of GPU cards in their desktop workstations for Design Visualizer. “Our minds were blown,” says James, adding that now 90% of its renderings are done using RTX series GPUs linked together to give 48GB of GPU memory, more than enough to process its most complex KeyShot materials and light environments “mind-bendingly fast”.

The drastic reduction in wait time for renderings has greatly improved TB&O’s efficiency, allowing the team to do more work in the same amount of time.

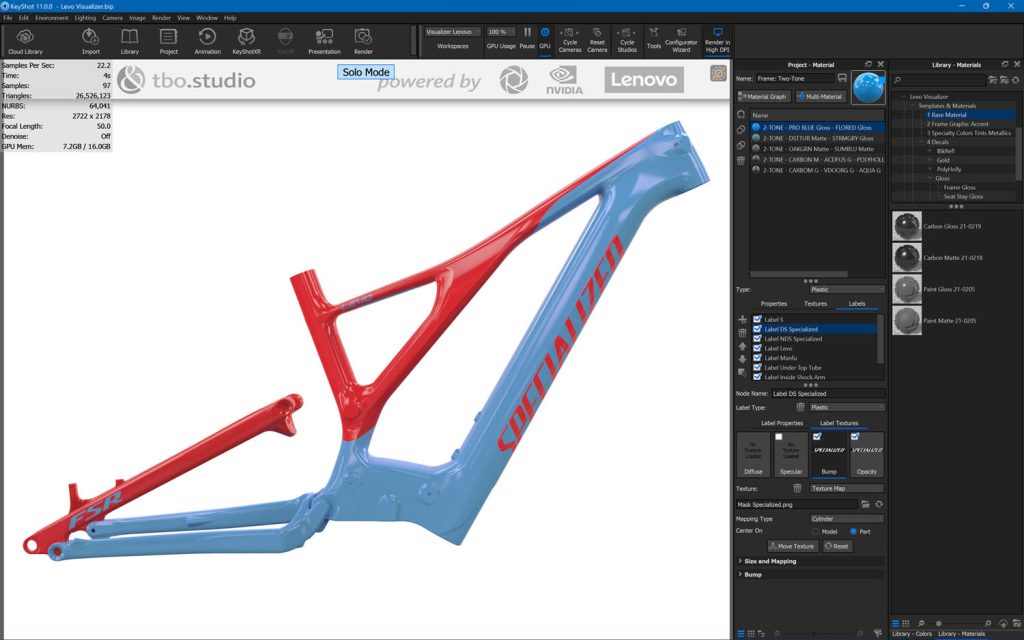

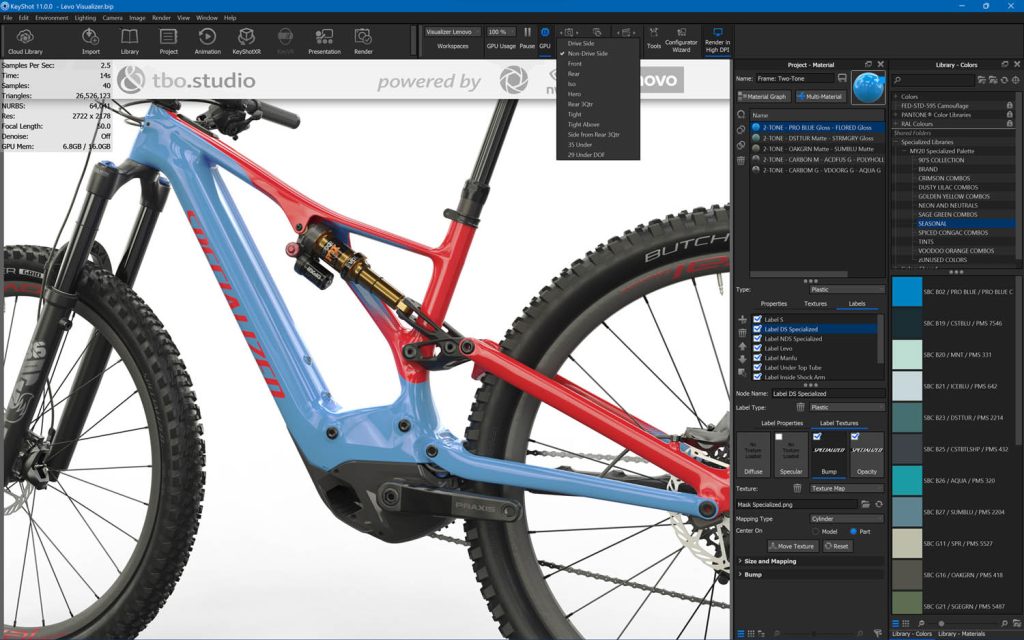

Breaking down TB&O’s design visualizer workflow

Going mobile

While the GPUs added the power, the desktop workstation set-ups used by Thomas Burke & Others were cost-prohibitive for its typical graphic designer client, who typically works on a laptop with an auxiliary monitor.

“We weren’t deterred by the notion that only people with machines like ours could do what we could do,” says James. “Expensive GPU cards in large, heavy and expensive desktop workstations were going to inhibit the implementation of this revolutionary way of designing products. We knew that, but we knew that technology would get smaller, just as surely as it will get faster.”

James says that while there are server and cloud-based alternatives, the commitment, planning and implementation of those act as “a barrier to broad availability throughout a department or across departments.”

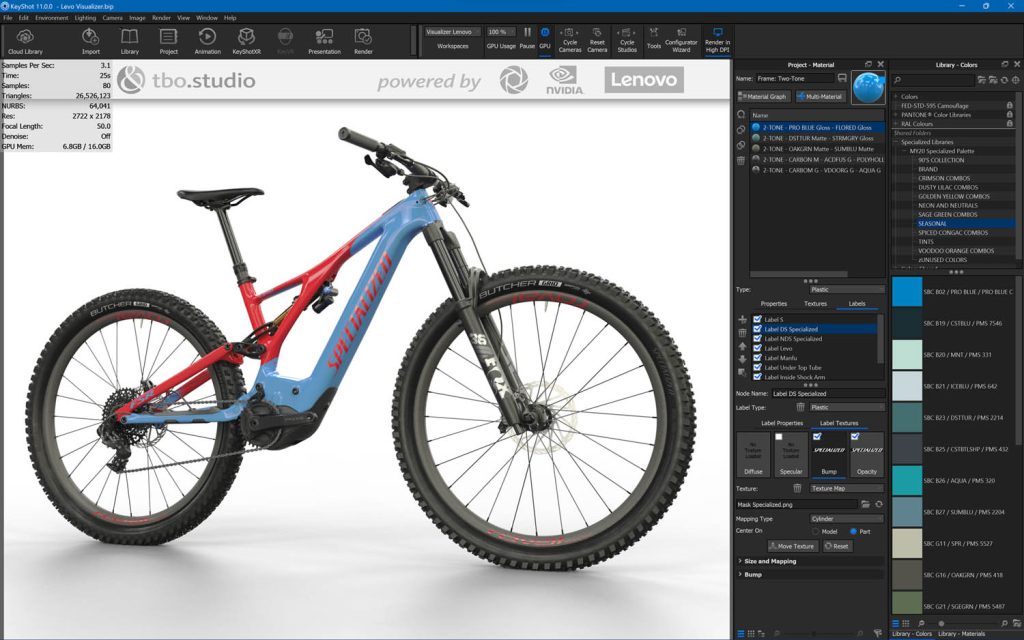

However, this all changed with the availability of the Nvidia RTX A5000 GPU inside the Lenovo Thinkpad P1 mobile workstation. It was enough to make the Design Visualizer workflow sing.

Nvidia and Lenovo lent Thomas Burke & Others a pre-production machine to test and validate the workflow. “When we started demoing the Design Visualizer with the Lenovo P1 Gen 4, even over Zoom, client interest was piqued,” laughs James.

In its tests, two RTX A5000 GPU cards linked in a desktop workstation remained considerably faster than a laptop with a single RTX A5000 chip. However, TB&O found that the RTX A5000 chip in a mobile workstation is still plenty fast enough with the added benefit of portability – and its clients agreed.

Thomas Burke & Others analysed the real-time, photo-real rendering using the RTX A5000 chip in the ThinkPad P1 in two ways. First, it allowed the screen to res up, noting how long it took to get to an acceptable level of clarity. The bike model is complex, with 26.5 million triangles and 64,000 NURBS. Yet, in most instances, crisp rendering can be achieved in about 10-15 seconds. This astounded the team.

Next, the team captured how long it took the scene to reach a certain number of samples with the RTX A5000 chip in the mobile workstation and compared that to the RTX A5000 card in the desktop workstation. Using this same compute-intensive file, the RTX A5000 chip in the ThinkPad P1 took 3:07 minutes to reach 256 samples. A desktop workstation running one RTX A5000 card took 2:13 minutes. Again, this was impressive. On top of this, the relative relationship held true for 512 samples and 1,024 samples.

James says when comparing the specs, “the RTX A5000 card [in the desktop workstation] has 24GB of memory available whereas the A5000 chip [in the mobile workstation] only has 16GB. This effectively means that, as materials get more complex and compute-intensive and as challenges such as depth of field are added, the RTX A5000 card is going to handle the job considerably better. However, what the Lenovo P1 with an RTX A5000 chip does for 2D to 3D design visualisation is game-changing.”

The new hardware and workflow have worked together to make real-time, photo-real product visualisation mobile, collaborative and cost-effective, prompting a drastic change in what TB&O is able to achieve for its clients.

“It changes where we can work and how fast we can work,” says James, adding that several clients have already asked TB&O to work with their product design teams to create similar workflows that free them to be more creative.

For Thomas Burke & Others, it has a downstream effect, too. What the team gets from the client to produce marketing collateral is going to be a lot closer to the real thing. That saves time and gives the client what it needs, faster. “We essentially sell our time. So, if we can render faster, and we can render more frames for videos and interactive experiences, we can be more creative in what we render,” James explains.

“If we can render in an hour what used to take a week, we’re apt to take more creative risks and push the envelope a bit further.”