In order to qualify to own a limited edition MB1 watch from the Bremont Watch Company, you must be a pilot who has experienced the ordeal of being sprung from an aircraft mid-flight by an ejection seat manufactured by UK-based engineering company, Martin-Baker.

Fortunately, the sale of most other watches in the Bremont range aren’t subject to the same restrictions. They do tend to share that aviation theme, however. The designs are inspired by the passion for flying historic aircraft shared by the company’s co-founders, brothers Nick and Giles English.

Today, the company is on a mission to nurture watchmaking skills in the UK. It already manufactures its own unique three-part watch cases (comprising bezel, central body and case back), at its facility near Henley-on-Thames in Oxfordshire. The intention now is to develop the skills and capabilities needed to make as many parts as possible by itself, in the UK.

In the meantime, Bremont carries out assembly and maintenance of every watch that bears its name and high standards are important. For example, the accuracy of a watch is routinely checked over a 15-day period and at temperatures ranging from -40C to +40C.

Bremont watches achieve an accuracy of -4 seconds to +6 seconds of variation per day, meeting the strict parameters laid out by the Contrôle Officiel Suisse des Chronomètres (COSC), the Swiss institute responsible for certifying the accuracy and

precision of wristwatches.

In short, these are watches designed for rigorous environments. They undergo altitude tests to 100,000 feet, salt fog and humidity tests, ejection tests for high g-forces, and vibration tests that simulate the 30-year lifespan of a helicopter.

Bremont – accuracy and reliability

In order to make more complex parts itself, and work towards the goal of manufacturing entire watch movements in the UK, Bremont Watch Company is working in partnership with machine tools company DMG MORI.

“We chose DMG MORI machines for their accuracy and reliability,” explains Tim Parker, production manager at Bremont. “We are manufacturing very intricate parts where quality and precision are paramount.”

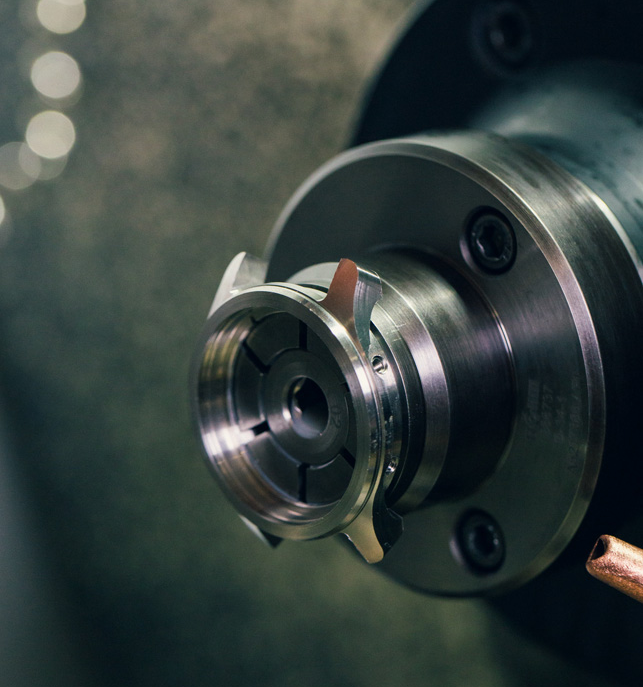

The company already has a number of DMG MORI machines in its workshop, including its NTX 1000 HSC, the NLX 2000/500 and an EcoMill 600. Towards the end of this year, it will take delivery of a second NTX 1000.

The NTX 1000 HSC is used for machining watch bezels, while the NLX 2000/500 produces the central body and case back parts of watches. Machining the bezel requires the full capabilities of the NTX 1000 HSC: cutting bar-fed 316L stainless steel and tapping M1.0 holes and producing 0.2mm-wide grooves to produce a complete part, ready for grinding, in one operation, using both the main spindle and the sub-spindle.

“We have 60mm and 45mm diameter 316L bar as stock material and we machine away around 70% of the material producing thin and complex parts,” says Parker.

“The rigidity of the machines helps us to achieve good tool life, despite the small sizes we use, and the flexibility of the DMG MORI machines and the three-part construction of the watch cases makes it easier to change production to suit demand for particular models of watches and evolve manufacturing methods for new designs and limited edition watches,” he says.

That’s important, as Bremont expands it range and targets wider audiences, both through its own boutiques in London, New York and Hong Kong, as well as retail partners worldwide.

“DMG MORI worked very closely with us to develop the cutting technology required, helping to build the different machining toolpaths and select the best cutters for our watch cases,” says Parker.

Rapid changeovers

Batch quantities of individual parts are small and rapid changeover between different models of watch is easy to achieve with the machines. “We run 24 hours, Monday to Friday, with a permanent night shift and the option of working over the weekend if necessary.

Material and tooling are on consignment, so we always have replacement and special tools available on site,” Parker explains.

Machine reliability is key to operating according to these schedules, so a service contract with DMG MORI is in place to ensure machines stay in peak condition. When the company recently moved its manufacturing activities from a site near Silverstone to its new facility, staff from DMG MORI worked alongside Bremont employees to get operations up and running within just two weeks, he says.

Bremont’s investment in the second NTX 1000 HSC will help it to increase capacity for its watches and also provide extra machining time to develop the manufacture of more watch components in house. The creation of new metal-cutting processes in partnership with DMG MORI, meanwhile, has given Bremont’s own engineers the new skills they need to make even more complex parts, too.

How Bremont moved more high-end timepiece manufacturing in-house

Default