SkyReal Suite – As industrial interest in virtual reality rises, We take a look at a software product born at Airbus and designed to help engineering and manufacturing companies dive into VR as a way to interact with complex 3D CAD datasets

SkyReal Suite was born out of an internal development project at Airbus to build up a set of virtual reality (VR) tools for design and production planning that could take advantage of the company’s high-end cave and powerwall environments, as well more affordable head-mounted displays (HMDs). These provide the means to view, manipulate and interact with large, complex 3D CAD datasets.

Today, the company exists as a separate entity, SKYDEA, dedicated to developing the engineering-focused VR software, which I recently got the chance to see in action.

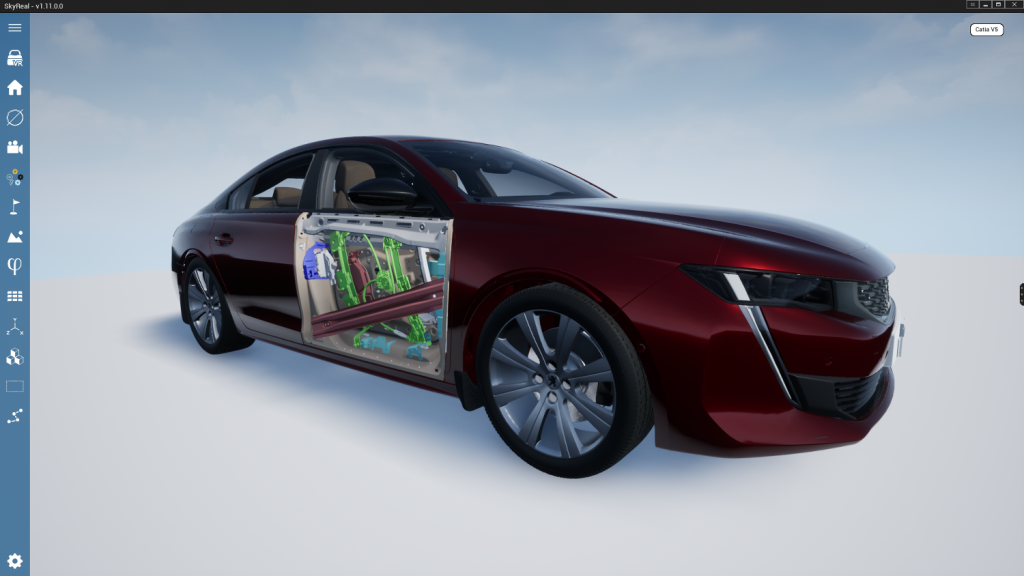

While the underlying graphics technology is Epic’s Unreal Engine, the SkyReal Suite is built not only to provide a set of tools that make the process of working with CAD data in VR easier, but also to add in specialist functionality for a variety of engineering and manufacturing workflows.

The Suite comprises two main elements. First, there’s XR Centre, which contains SkyPrep, which handles pre-processing of CAD geometry to ensure it’s suitable for efficient VR workflows, scene set-up and model adaptation and enhancement. You can set up more forms of interaction and handle data storage and sharing in XR Centre, too.

Second, there’s SkyVR, where you view and interact with the data you’ve created, via a wide range of VR headsets, caves, powerwalls and standard 2D displays. So, shall we take a look at what SkyPrep and SkyVR can do?

SkyReal – SkyPrep: Pre-processing for VR

Anybody who’s engaged in a meaningful way with the world of VR, particularly when using general-purpose tools such as Unreal or Unity, knows that getting hardcore, super-precise engineering CAD data into a state that’s useful and efficient in a VR engine can be a proper pain in the arse, not to put too fine a point on it. Data from CAD isn’t suited to VR and needs to be tessellated as a starting point.

The issue here is that the tessellation process takes something that’s already complex and heavy-weight and, in many cases, makes it more so. So a process of decimation, of filtering out inconsequential detail and small parts (particularly in large assemblies), in order to make it more efficient, is fundamental. Then you move on to the process of setting up materials (assuming they haven’t ported across from the CAD system or via the export format), as well as lights, scenery, animation and interaction items.

SkyPrep assists you with this work. Its dashboard manager will provide tools to import geometry from a variety of sources, filter it and convert it into SkyReal assets. The system, due to its background in the complex world of Airbus, offers a pretty impressive set of import options. IGES, STEP and STL are all there, along with Parasolid and Acis.

Alongside these, there is also a good level of native data support, from Catia (both as 3Dxml and CATproduct), Delmia, Creo, Inventor, Rhino, Solidworks, NX/ Solid Edge (using JT data), as well as some simulation results formats.

The import process provides you with a number of options to simplify your geometry and these need to be understood to get the best visual quality while maintaining performance.

Aspects like levels of detail are also key to understand. Each data entity within a scene can hold multiple levels of detail, from coarse to high quality, and the use of those is dependent on the viewers’ distance from them.

Getting this right is key, particularly when you’re dealing with large-scale, heavy scenes.

The system also handles aspects like generation of a physical envelope (critical if you want to use the system’s physics engine for collision detection, which we’ll discuss later), as well as handling of duplicates (SkyReal is capable of using a single instance of a part and simple replicating it where needed in a scene).

Once you’ve set your parameters and options, you then need to define your output. The main option is, obviously, to generate a set of data that can be read into the SkyReal application set.

It’s also possible to export native Unreal engine project files without any of the added SkyReal functionality.

SkyReal Suite – Into the virtual world

The next part of the workflow is to use SkyReal to view, interact and collaborate with the data you have just created.

What’s interesting is that SkyReal has built this system to be collaborative from the very beginning. Here, the underlying Unreal technology on which it is built pays dividends, making it a multi-user environment from the ground up. SkyReal takes this technology and extends it, making it much more usable for the engineering and design user.

In the most basic mode of operation, you have a set of product geometry and a scene into which you’ve placed it.

Using a combination of tools in SkyReal, you’re able to move about the scene, inspect geometry and get a sense of position and scale – all the core benefits of VR. A number of tools enhance the process, including inspection tools for sectioning, visibility controls and, of course, the ability to pick up and rotate parts or subassemblies.

What’s interesting is that this can also be performed with full collision detection enabled. It’s also possible to start to define more complex interaction methods and triggered events. Push a button, for example and an elevator will rise or descend; walk into a specific area and the lighting changes.

The team’s roadmap is also looking interesting, with highlights including the ability to import simulation results and CAD geometry together

The implications of this are two-fold. First, you can keep things simple and static, enabling quick and efficient design review. But second if you want to start adding in more complex interaction, you can.

To help with this, SkyReal provides a large library of pre-baked interaction tools that you can quickly apply to your scene.

The same is true of your visual representation of your geometry and your scene. The display can be pretty standard fare for engineering VR, but if you want to get more complex, add more lighting, more realistic materials, it’s all possible – it just takes a little more effort.

SkyReal is taking this same approach to build out a number of tools to enable specific workflows and processes.

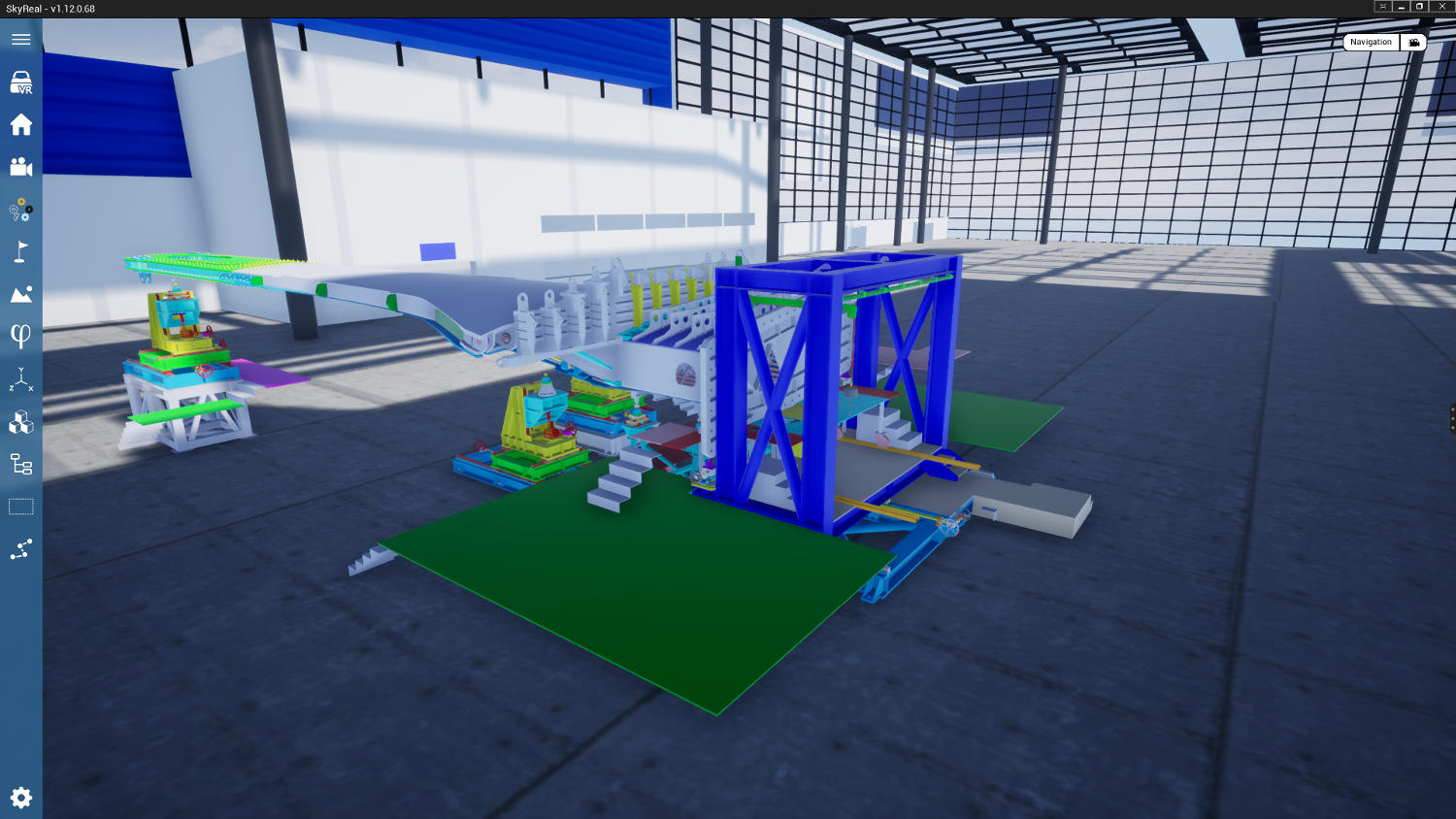

One example is the classic use case for VR in training and evaluation, using intelligence models combined with realistic VR. Using this, you could get a team ready for an assembly line before that line is even built, for example.

Another use case might be getting an on-site maintenance team ready for a job, familiarising them with potential challenges, long before they ever travel to that site in person.

There’s also the Manikin tool, used for placing digital humans into your 3D scene to evaluate configurations of assembly processes.

Using the HMD controllers, you can become the digital manikin yourself, seeing what they see and manipulating their hands. There are even advanced controls to link the digital manikin on screen to a fully tracked set of markers (such as Vive Trackers) on a real human in a 3D space.

It would be entirely feasible to have an assembly technician work through a virtual assembly sequence, record their movements and see that applied to the digital manikin.

With the use of collision detection, that digital manikin would also stop at points of collision, allowing reach and accessibility to be very quickly gauged. And of course, when finished, you have a virtual recording of how tasks are performed and where problems might lie.

This could then be replayed, with third parties watching the same session to find room for improvement – either via a standard monitor or by walking around a replay in 3D.

The SkyReal team has also showcased an interesting set of tools to overcome the unidirectional nature of VR. More often than not, a workflow is linear: you take your CAD geometry, convert it, put it into the VR world, collaborate around it and you’re done.

What the SkyReal team has done is built two sets of tools that allow you to conduct design review as normal, make changes and then pass that data back into the associated CAD/PLM system.

Annotation methods, meanwhile, enable you to position mark-ups and notes on your model, which are then made available for further review in the CAD/PLM system.

Extending this idea further, consider retrofitting an older-model aircraft or marine vessel: you would have an existing set of data and a new set of cables, harnessing and/or pipework you’d want to route through that product to update its functionality.

SkyReal has built a Pipework design tool that supports the visual positioning of these pipes (and soon, wiring looms) directly in a full-scale, virtual mock-up, while respecting the minimum bend radius, which can then be passed back through to the authoring design and engineering system for full workup.

The benefits of doing that in a VR environment are subtle, but powerful. As well as being able to see precisely where fit and routing works (or doesn’t work), it would be possible to iron out accessibility and reach issues at a very early stage of the design process, saving a ton of time downstream and perhaps rework later in the design cycle.

SkyReal Suite – Collaboration with XR Center

All of these tools are, for the most part, available in the SkyReal product and are intended to be used predominantly by a single user, perhaps with others observing via a connected display.

But what if you want to bring together a more extensive collaboration session? In today’s world, connecting parties might be spread right across the globe, rather than based in centralised office locations.

This is where SkyReal’s third application set, XR Center, comes into play. This is a web-based hub through which collaboration sessions are driven. Data is centralised, managed and distributed from here. XR Center enables organisations with more complex needs to conduct their VR sessions, not only handling data access (it manages user access), but also distribution of data and collation and reporting of design review sessions.

In conclusion

What SkyReal has built is impressive, considering that the team has only been going at it for a few years now. It’s likely to resonate with companies in the design, engineering and manufacturing industries, where interest in taking advantage of the benefits of VR adoption is on the rise.

After all, HMDs are more powerful than ever and costs have never been lower. And they’re backed up by a set of baseline VR engines, such as Unreal and Unity, which gives developers access to well-funded and quickly advancing platform options.

It will be interesting to see which vendors take advantage of this set of technologies and provide the real-world functionality that design and engineering teams need. Will it be the older guard of VR developers, accustomed to handling huge implementation projects on a consultancy basis – or will it be newer, more nimble start-ups, which outmanoeuvre the dinosaurs by providing freshly thought-out and cleanly delivered tools?

SkyReal falls 100% into the latter camp. It has taken underlying technologies and, in collaboration with customers in some pretty demanding industries, is building out a set of tools that not only provide review and collaboration, but also extend into other areas such as factory and production planning, as well as training and simulation, all with a clean, modern approach.

The team’s roadmap is also looking interesting, with highlights including the ability to import simulation results and CAD geometry together into your VR session, to overlay animated simulation data on the CAD geometry, as well as first explorations into mixed reality device support. In short, SkyReal’s work is first class and the company is definitely one to keep an eye on.