Femap 12 – Simulation is still a process that frequently requires a specialist set of tools. We take a look at one of the finest pre- and post-processing systems on the market and discover what makes Femap really sing

Let’s talk about simulation: it’s been an important part of many engineering-led workflows for decades now but, more often than not, it’s still work that is performed by specialists. Also, despite the promises made by CAD vendors over the years around the great potential for CAD-integrated simulation, it’s still not part of the mainstream.

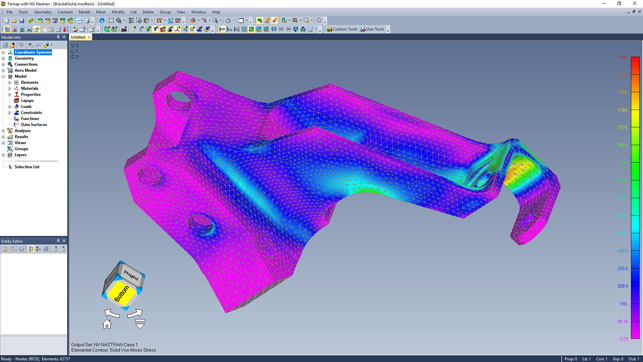

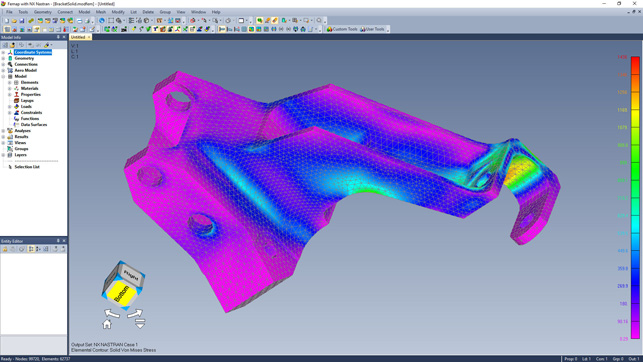

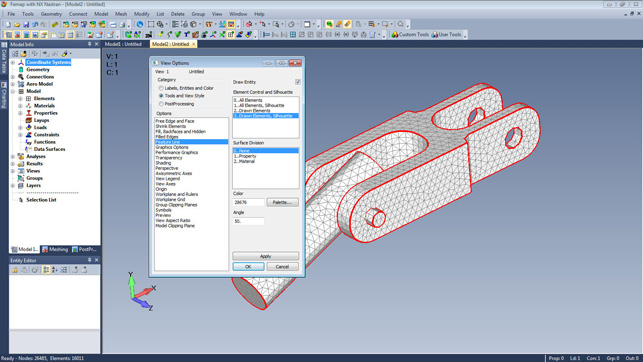

In Femap 12, you can now interactively move and adjust graphics screen entities including viewing axes

What this means is that, when you set aside the focus on CAD-integrated simulation, you’ll see there’s been a great deal of work on continuing to develop rich sets of tools for the more specialist end of the market, and that these don’t always get the attention they deserve.

These higher end, specialist tools typically consist of solver technology, alongside pre- and post-processing systems. The solver technology provides the computational engine to solve problems, while pre/post-processing helps with study set-up (for example, defining a mesh, boundary conditions, load constraints and so on) and subsequent interpretation of results.

Siemens PLM’s pre/post-processor is called Femap and has been on the market for a good few years. It may have started life as a graphical front end to Nastran, but Femap has since grown to support not just the various flavours of Nastran, but also to connect to Ansys, Abaqus, LS-Dyna and Marc.

Femap 12 – user experience

In terms of what to expect when opening up Femap 12, the system has been through something of a refresh in the last release cycle. It’s now looking a lot cleaner and more logically laid out.

In addition, work has been done on how you interact with screen entities. There have been improvements to graphics processing, in order to take better advantage of any GPU hardware present (either AMD or NVIDIA-based). The addition of the now-standard ‘view cube’ device for manipulating your view, meanwhile, enables quick inspection of parts.

The new graphics engine allows you to switch on a ‘feature’ view that shows either edges of CAD surfaces or curvature changes, which will be really useful when working with more complex CAD geometry. And items like contour legends, view axes and such are all much more customisable.

It’s worth noting that these updates are on top of tools that have been in Femap for many years. These include a wide range of tools for organising and abstracting your CAD geometry and for building models from scratch – things like groups and layers will prove useful for many, as they have done for years. So, shall we explore how Femap works?

Femap 12 – pre-processing

The first goal of Femap 12 is to allow you to either build finite element models from scratch or to import and repurpose CAD files from a variety of formats.

While in some cases, this might be a simple case of meshing, in many instances as you start to explore more exotic forms of simulation, it will involve abstracting away from the raw geometry. This is to build more appropriate or lightweight representations of a part or assembly – whether that’s defeaturing models (such as removing small features, fillets, chamfers and small parts) or constructing mid-plane or beam element models.

While Femap boasts an impressive range of mature and well-developed tools, there’s always room for enhancement with each release. In the Femap 12 release, some key updates are worth exploring.

The first is that stitch has been worked on, in order to combine surfaces into a single body; this will prove useful for working with those less than ideal models where individual surfaces don’t connect well.

This now allows you to specify a maximum tolerance and uses an iterative approach to get surfaces stitched together without too much hassle or manual rework.

There’s also been work done on Boolean operations to do a better job retaining combined curves and boundary surfaces, which are typically used to reduce the complexity of geometry to improve mesh quality.

There’s also a new ruled surface option to allow building between curves, with much more control over tangency (either to connecting surfaces or a specified vector). Again, this seems like a small update, but if you’re trying repair a complex model, then it’ll be godsend.

On the subject of defeaturing a model, there’s also been some under-the-hood work done on speeding up feature removal – for example, to reduce the time spent on removing a large number of small hole features from minutes to seconds.

The last update we’ll cover for geometry process is the new beam centreline finder. While there’s good support in most systems for building beam element models from basic framework, this is a cut above what’s typically offered and gives you much more control.

It’ll find your centre lines, locate the most appropriate section property from its own library (or prompt for input where a match can’t be found), then apply them across the model. It’ll work as well in structures where each solid has a unique section profile. If you’re working with tubular structures, it’ll handle the intersections as well.

New feature and silhouette lines aid model visualization by outlining model edges and features

Femap 12 – mesh design

Moving on from geometry processing, a key part of the pre-processing workflow is the creation of the mesh.

As you’d expect, Femap already had a rich set of tools for creating meshes for a variety of study types and has done much to enhance that existing functionality over the years. That said, there’s still room for new tools and redesigned workflows in the latest release.

One such example is the new washer and pad meshing tools; these help you create mapped meshes around holes and slots to improve mesh quality, thus improving overall model accuracy. While there were existing tools to work with the most common circular holes in the product, these have been extended to work with non-circular holes. That’s ideal for nonstandard openings, whether for washers, holes in 3D forms or items like gaskets.

Elsewhere, there’s been some interesting work around reusing geometry and meshes in a more efficient manner. Now, if you grab a selection of geometry that has a mesh ‘attached’ and either move, copy or mirror it, it’ll take both the geometry and the mesh.

If there are any other items associated with that selection (such as loads, constraints, connecting regions), it’ll replicate those, too. The same capability has also been introduced for polar arrays. For those users who like to keep a track of how entities are numbered, these tools will also respect any numbering conventions in place.

On the subject of numbering schemes, work has also been done on how numbering of entities is handled when constructing models from separate mesh files. It might be the case that you need to split up work across a team or for pure performance benefits, and then bring those separate data files together.

The model merge command now affords you full control over how numbering is handled during your import and rebuild process, as you bring disparate meshes together into a single structure.

Femap 12 – post-processing

While we’ve covered most of the updates to pre-processing, there’s also been a lot of work done in recent releases on the post-processing aspects of Femap, both at a functionality level and how the system connects to other solvers.

On the post-processing front, there’s been work done across how you can display your results. For example, while previous releases took a ‘one size fits all’ approach to colour ranges and their application across a results set, you now have much more control.

Alongside this, dynamic criteria plotting allows you to select a criterion and vary it to your chosen limits or values and immediately see how the model looks on screen.

You can use the ‘Generate From Criteria’ operation to group passing elements. Both of these make inspecting complex models much easier, letting you gain a quicker understanding of your results.

Elsewhere on the post-processing front, Femap has been gaining more extensive charting tools in the last few releases, outside of the typical X/Y plotting tools.

The idea here is that rather than using an another system (for example, Microsoft Excel), you can do more work inside Femap, keep it linked to your data and keep things up to date, in a single place.

Finally in post-processing functionality, the system has at long last been given its own automatic report generation tool. We all know the type of thing this entails: the ability to set up your plots and charts and have the system spit out a pretty generic report.

These things usually aren’t much cop, but do a least give you a means to quickly generate all of your plots in one go.

Femap’s answer to this eschews the typical HTML approach and instead delivers report in Microsoft Word format, saving another step along the way.

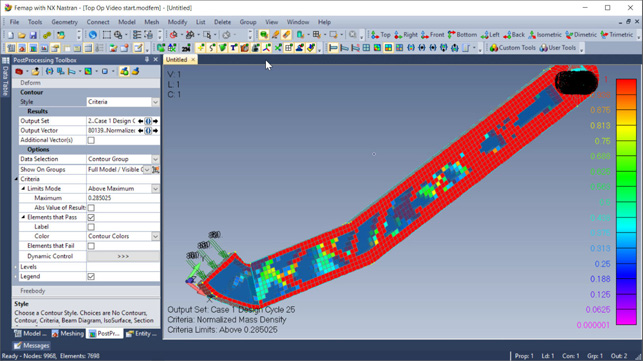

Topology optimisation is reintroduced expanding solution capabilities to optimise design performance

Solver connections

Alongside the functionality updates that we’ve already discussed, work has also been carried out on how Femap connects with the various solvers out there.

As you would expect, its connectivity with Siemens PLM’s own NX Nastran solver is first class and, for this release, Femap also now supports the recently introduced topology optimisation.

The product has also been updated to support a NX Nastran solution which leverages technology from the Samcef solver, which Siemens acquired when it bought LMS. This is useful for simulation of the delamination of composites.

And if you’re an Ansys house, Femap’s connection to that system has been completely reworked to support modern element types, material definitions, boundary conditions, and analysis options.

In conclusion

Femap 12 is a fantastic bit of kit for those looking to push their use of simulation that bit further and to get into some serious analysis work.

Yes, it has been tailored to work perfectly with Siemens PLM’s own Nastran code, but it’ll also happily work with some of the other leading structural codes out there.

As a toolbox to allow you to get into the nitty-gritty of both study set-up (which can involve a lot of idealisation and abstraction) and of results interpretation and reporting, Femap is first class.

It’s also worth noting that, with its maturing API set, Femap is also finding a home in organisations that are looking to automate their simulation use when it comes to handling some routine or repetitive tasks.

All in all, if you’re serious about simulation and analysis, Femap 12 is well worth investigating – so jump on that trial and see what it can do for your organisation.

| Product | Femap 12 |

|---|---|

| Company name | Siemens PLM |

| Price | from £233 per month |