In the first of our planned quarterly catch-ups with Onshape, Al Dean takes a good look at what’s been happening with the cloud-based design system, now that it’s out of beta and available for commercial use

The announcement and subsequent launch of Onshape has possibly been one of the most exciting things to happen in the 3D design and engineering software market in recent years. It’s not often, after all, that we see an entirely new company enter this sector.

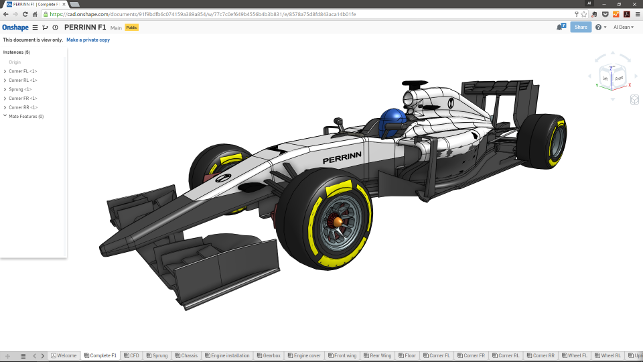

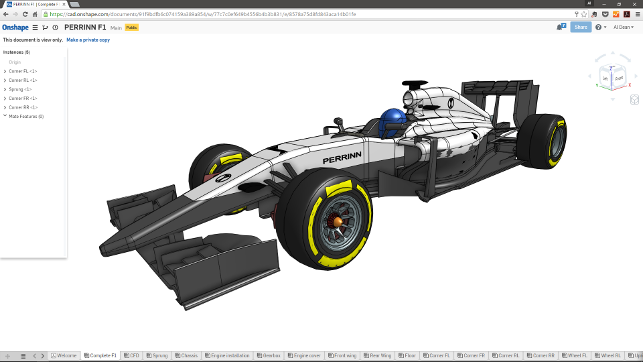

Perrinn Limited is using Onshape’s collaboration tools to build a global team of racing engineers See box out below for more details

As we’ve discussed before, the team behind Onshape honed its skills for many years at SolidWorks (and at other companies), and the company’s progress to date has been a rollercoaster to watch.

Along the way, it’s bagged huge funding ($100 million to date), plus a substantial community of users. During its beta programme, the company reckons that over 10,000 users signed up to Onshape and, between them, spent almost half a million hours logged on to the system.

The company has also launched the pricing for its system (a pretty straightforward $100 per month) and tied down the details of its free plan – ten private models, 100MB of storage for those models, and unlimited numbers of public models, as long as you stay under the 5GB limit.

More recently, it launched the beta of its App Store, which sees partners bring on stream a wide variety of applications and services designed to work alongside Onshape, from simulation and rendering, to fabrication and machining.

We’ll be taking a look at the growing range of Onshape partner apps next issue, but this month we’ll focus on what’s new and improved in the core service offering.

Onshape – Core modelling updates

If you’ve been tracking its development, you’ll be aware that Onshape is centred on a set of tools that allows you to create geometry using a familiar palette of both solid and surface modelling tools.

By that, I mean that the tools are pretty consistent with almost every other solid modelling system out there, from revolves and extrudes to sweeps and lofts, fillets and chamfer.

Onshape uses a history list to track your feature-creation and editing operations and, due to its cloud-based nature, keeps a complete list of all changes. Not many systems can boast entirely unlimited undo/redo like this.

In the last few releases, this core set of tools has been enhanced to include, for example, more powerful termination results in an extrude and greater control over how lofts are constructed. With every update cycle (a cycle typically runs for three weeks), users are finding that most operations have grown in their capability.

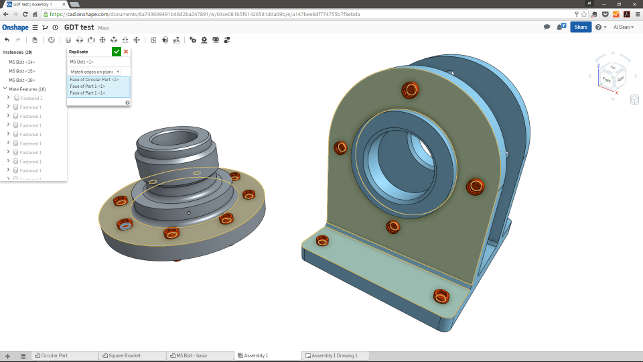

The assembly modelling tools are growing at a similar clip, being fleshed out quickly and pretty consistently.

The end result is a system that allows you to build complex parts and assemblies in the manner in which you’d expect – but we’re also starting to see signs of fresh thinking, too. An excellent example is the recently introduced Replicate operation.

This, in short, enables you to grab a part and its mating conditions in an assembly studio and then copy it into another set of geometry. Assuming that the mating conditions match (for example, holes are the same diameter), then the part will replicate.

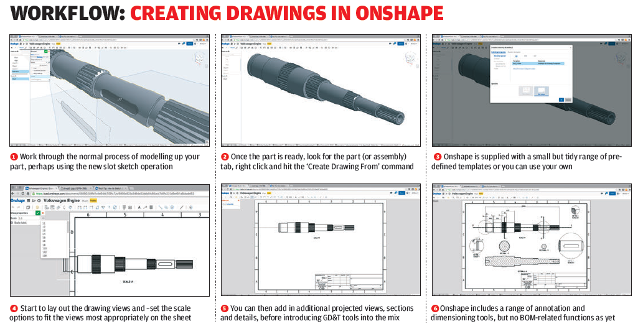

Onshape – Drawings

When we last looked at Onshape in the September 2015, the Onshape team had just announced drawing support, by partnering with a company called Graebert.

Alongside fleshing out pretty standard modelling tools, Onshape is gaining some new innovative functions, such as Replicate

If you’ve not come across Graebert before, it’s a company best known for developing AutoCAD clones – of which there are admittedly many. Still not ringing a bell? If you’re a SolidWorks user, or have downloaded and used Dassault’s DraftSight application, then you’re already using Graebert’s products.

Alongside its desktop-based applications, the company has migrated other products to the cloud, which is what allows Onshape to take advantage of its drawing capabilities.

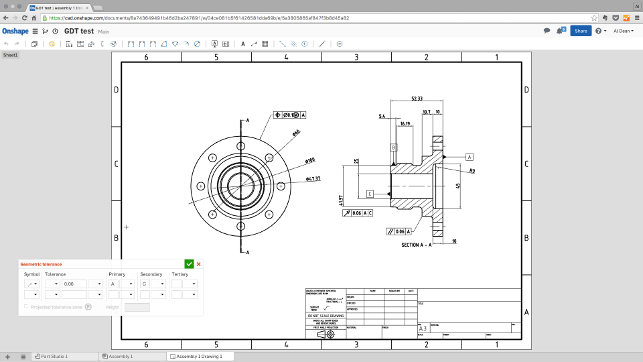

The toolset, four months after launch, is pretty solid and the workflow follows a familiar pattern: you take your part and create a drawing that links to that geometry.

Onshape is supplied with a range of templates (conforming mostly to ANSi and ISO standards), but you can also develop (or import) your own. You then lay out the drawing views, which are extracted from the model.

The first one you define sets up the whole system in terms of scale, but you can then add in additional projected views, sections and details (that said, it’s worth noting that you can’t currently add details of sections, as you’ll see in our workflow below).

You then add those all imported dimensions, tolerances and other annotations to your model.

There’s a good set of GD&T tools already in place, with datums and feature-control frames added just before the New Year. That said, both parts lists and balloons currently need to be created manually.

A quick check of the Onshape forums shows that this is in development at the moment.

While the goal of Onshape is to keep things digital (remember, drawings, like 3D models, can be shared and collaborated on very easily using the cloud), you’re probably going to want to print them off at some point.

Onshape doesn’t support print directly; instead, it gives you the option to export drawings as a PDF, or via DWG or DXF, depending on your preferred method.

Collaboration & management

Alongside the core modelling and draughting tools, data management and collaboration tools are also worth a look.

Due to its browser and cloud-based nature, Onshape has some interesting and inherent capabilities for data management.

As we’ve discussed before, it features version management, combined with branching and merging tools that allow you to track the development of a part and assembly pretty closely.

During the early stages of design, when parts can take different paths, the branching and merging tools are ideal for keeping versions centralised and manageable. But it is in the latter stages when the versioning really comes into its own.

While Onshape allows you to define the current state of parts (for example, ‘in progress’) it doesn’t, as yet, have any revision control in place – but I wouldn’t mind betting that’s coming soon. Work is also underway to enable greater workflow control between different users working on the same documents.

Starting with the ability to pass on control of a set of data to another user, this is an indicator that change management is going to get attention.

In conclusion

Now that it’s out of beta, it’s a fair bet that the team behind Onshape considers its system ready for real production work.

Whether they’re right or wrong really depends on the work that you, the user, needs to get done. The modelling tools are advancing nicely, with all of the options and variables you typically need to get started.

Drawings within Onshape are starting to mature nicely, but there are still some key capabilities missing (such as intelligent BOMs and ballooning)

It’s the small, incremental additions, however, that will give you a better set of tools and make Onshape comparable to the tools you’ve been using for decades.

A great example is the Replicate function: this addition shows that the Onshape team is genuinely looking for new ways to improve workflows and tasks, rather than just flesh out a set of CAD capabilities that already exists elsewhere.

The drawing tools, too, are shaping up nicely, but unless you’re working on single-piece parts and looking to define manufacturing data for them, the lack of automatic Bills of Materials (BOMs) generation and intelligent ballooning could well be a drawback – for now.

BOMs, after all, are the lifeblood of many engineering projects and Onshape has the potential to do some very interesting things here. A BOM doesn’t just have to be a tabular form inside a drawing sheet.

Instead, by taking BOMs to the cloud, you’ve got the opportunity to interlink them, making them shareable and referenceable in a way that transcends a technical drawing. That might mean sharing purely tabular data with colleagues in procurement, or linking BOM data to ERP or MRP systems. There’s a lot of potential here.

To sum up, Onshape is getting there. For users of the more traditional 3D modelling packages that have been around for years, its toolset is still emerging and maturing.

But to dwell on that fact is to miss an important point: Onshape really isn’t about providing yet another set of 3D modelling and drawing tools. It’s about finding new ways to work that better match the needs of today’s designers and engineers.

As such, the real innovation is going on in the background, as the Onshape team works to build a platform that can handle multiple users, working on the same data in a freeform, yet controlled, way.

The opening up of the App Store, meanwhile, also demonstrates that the company is serious about helping users achieve their goals in areas such as rendering, simulation and fabrication.

Onshape in use: Perrinn takes on the racing giants

Racing drivers certainly get an adrenaline rush from their activities – but for their many millions of fans worldwide, watching a race remains a relatively passive experience.

They may catch a blur of their favourite car or a gust of exhaust fumes, but they have little influence over which car crosses the finishing line first.

That could change if engineer Nicolas Perrin gets his way. Perrin, the founder of Perrinn Limited (the extra ‘n’ was added to make the brand stand out, apparently), is attempting to turn the

racecar design world upside down, even in an industry where every gear change is a closely guarded secret.

What he plans to do is make his designs available to his opponents and the wider public alike, in a move that might, on the face of things, look like a regrettable sacrifice of competitive edge, but which he believes could help him source new design talent.

“Sports [are] very powerful for bringing people together, so we can go a step further and effectively make this team, our design team, something a bit more special,” he explains.

“Building a car is a team experience. The Internet provides services to connect with friends, or search, or do things like that, but we want to use it to create a better team of designers, working from any location in the world, while allowing the public to access our design to learn or simply to follow our progress.”

“If you’re a football fan, you can follow the game easier if you’ve ever played it yourself,” he continues.

“You can just take the ball and go do it. The difference with motorsports is that technology is a big barrier for people to truly feel like they can get involved and actually play themselves.”

Perrinn Limited currently has a core design team of five professionals split between England and France. To facilitate internal collaboration and with outside partners and the public, the company chose Onshape, which enables multiple authorised people to simultaneously work on the same design from any location, over the Internet.

“The advantage of open access is that many people can check what you’re doing in real time, learn from it and potentially even work on the project as an expert,” notes Perrin, whose goal is to develop cars for the international Formula 1 and Le Mans 24 Hours races.

Using Onshape allows Perrinn Limited to instantly share its car designs with fans around the world without the need for them to purchase expensive CAD licenses, to download or install any software.

Non-CAD users can follow the progress of the design without any knowledge of engineering, while designers can access the model anytime in the cloud, using any computer or mobile device.

Perrinn’s slogan is “We Are a Team” and its founder hopes to recruit that team from a far wider pool of candidates in future. “We’re trying to start a movement to bring everyone a bit closer together,” he says.

The company’s LMP1 design, for Le Mans, is now ready for production. The Formula 1 car, meanwhile, is still in the early design stages and could take between two and three years to fully develop, but its design is already fully accessible as an Onshape Public Document.

| Product | Onshape |

|---|---|

| Company name | Onshape |

| Price | Free to $100 per month |