Materialise Magics 23 – As the world of additive manufacturing becomes more diverse and complex, pre-processing software has become a hot ticket item. We take a look at the latest release of the legendary Magics

With its background as one of Europe’s leading and largest rapid prototyping bureaux, Materialise offers unique knowledge of and expertise in the whole prototyping process, from the importing of parts from CAD systems, through pre-processing and build preparation, and into product cycle management.

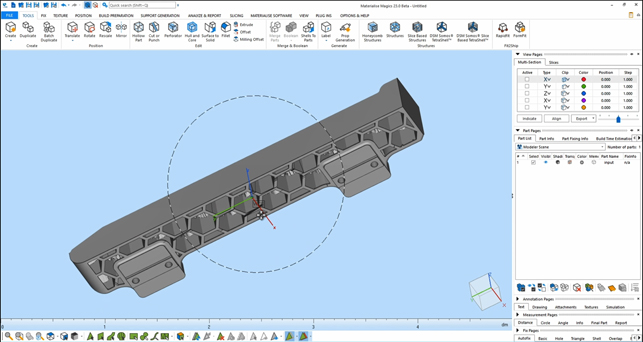

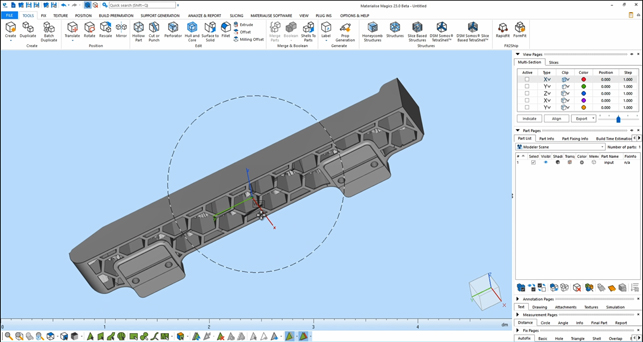

Magics now includes more control over the creation of honeycomb structures, ideal for informal lightweighting of parts

While the majority of DEVELOP3D’s readers might know the company as a service provider that delivers parts pretty damn quickly, it has also been developing and selling its range of software products for many years. Its flagship product is Magics, which initially began as an in-house tool for preparing SLA builds.

That said, it has expanded significantly over the years and become key to many organisations’ workflows. So shall we explore what it can do and what the experience is like?

The user experience for Magics has been refreshed in recent release, but the core usability of the system remains. The tasks for which Magics is intended are as varied as they are complex, so it’s natural that the system is split up into chunks of functionality, both in terms of use and also licensing. After all, if you’re running a plastics sintering machine, you don’t really need a licence that includes metals as well.

In terms of how the system is laid out, there are a few changes for the Magics 23 release, most notably for existing users.

For example, the most common operations and options, such as error visualisation, have been moved to the bottom of the window and are persistent, along with other commonly used commands that already made the move, such as view manipulation and selection filters.

Modelling & editing updates in Materialise Magics

While Magics built its reputation on fixing and preparing data for rapid prototyping, the system very quickly expanded into a set of very specialised tools for adapting parts to the peculiarities of a variety of additive manufacturing processes. While there have been tools for shelling, splitting and joining parts together for some time, this release sees a few core additions to these.

One such addition is the ability to add in a fillet to a part edge. While this might not sound like a big deal, remember that Magics is intended primarily for use on mesh-based data (although it also has a rich set of CAD import options), so that’s not quite as simple a task as it might sound.

Essentially, you select the edge and the system will add the fillet that you need, directly to the mesh. Of course, they’re not parametric, so it’s a one-step process to get it right. This might sound like a strange option for a mesh-based additive preprocessing system, but it’s been added to help those users looking to remove stress concentrators in additively built metal parts. Smoothing out those sharp edges can really help with this.

Another new modelling update relates to the honeycomb structure building tools from a previous version. The tools allow you to build up a honeycomb structure within a given volume, with the possibility to make it self-supporting, in order to lightweight a part.

The latest update now gives you a full preview and the ability to tweak the rotation of that structure so it better fits your requirements. While in these days of generative design talk, the honeycomb may seem decidedly old school, it’s perfect for lightweighting casting masters or patterns for larger builds.

On the subject of Boolean operations, this release brings together a number of different operations into a single dialogue.

You can now use the same dialogue to carry out any union, subtract, clip and so on, with a clear preview of what you’re doing and smart use of colour to identify the geometry you have selected, making the whole process both more interactive and more clearly worked-through.

The last update on general modelling that I wanted to discuss is the creation of material testing forms. While Magics has had the ability to create single and doubletensile dogbones for material testing, you can now create rounded tensile bars as well – as are used, for example, in fatigue testing. What’s also interesting is that you can now integrate these into various machine set-up templates, so any builds run on specific machines will also include the material test parts you might need for quality control and traceability purposes.

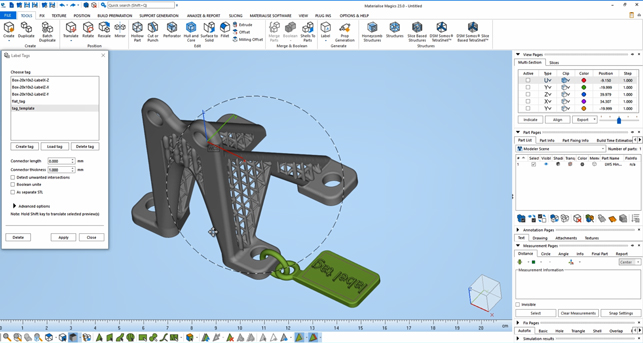

Part labelling

Moving onto more specific creation tools, the tools for labelling and tracing parts have been improved. For example, part label tag creation tools allow you to quickly model up the geometry for a tag for your part that gets printed with it, so you can identify the part as it goes through post-processing.

(Remember, the target audience for Magics is high-volume 3D print users.) This functionality has been expanded to allow you to use any shape of primitive for that tag, allowing you to perhaps fit in more information or to use a variety of shapes to identify different customers or treatment requirements quickly.

Also related to this is the ability to add a data matrix label (a square barcode label) into your part’s surface, either as an engraved debased feature or as an embossed set of faces. You define the size of the label, the number of pixels, your data, then select the geometry to build it into or onto. We’ve also seen examples of data matrices built into the internal volume of parts, so they can only be identified when passed through an industrial x-ray – again, that’s entirely possible with these tools.

Part labelling has become more powerful, giving users more options for separable labels as well as built-in data matrix labels

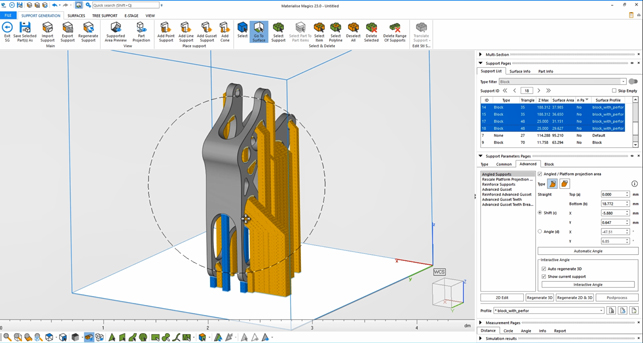

Support generation

Since its inception, a key point of focus for Magics has been providing the user with full control over the pre-processing required to manufacture parts effectively using a variety of additive manufacturing methods. While Materialise’s initial focus was SLA (a function of the dominance of the process at the time), this has expanded hugely in recent years to cover the gamut, not just in polymer-based processes, but also metals.

What has differentiated Materialise’s approach is its focus on providing much more control over the support generation process, way above and beyond what you might typically get in the systems supplied with most machines (which are, invariably, pretty automated and fixed).

This release, as you might expect, continues to add new features and refine the existing set of tools. In generally applicable updates, there’s been a shift in how you manage your various support building profiles and parameter sets. As you might imagine, Magics is targeting organisations running multiple processes, machines and materials, so you’re able to define all of these combinations in individual profiles, then share them with those colleagues who need them.

There’s also been specific work done on the generation of supports. If you’ve done your background reading, you’ll know that the design of supports and how the part connects to the build platform is just as key to a successful build as the orientation and design of the part itself.

While Materialise Magics has some rich functionality already in this area, there’s always room for greater control. In Magics 23, this work focuses on the automation of support optimisation. In those instances where self-support is needed, it’s key that there’s enough support there to do the job and to allow the form to be built accurately (and without deformation), but also to ensure that it’s not so heavy that post-processing and breakaway become a painful business.

In order to save time during build preparation, part-to-part contact can now be avoided automatically with the automatic angle of the supports. Materialise Magics 23 also gives you the ability to finetune all support forms, in terms of angling supports away from the part, directly from the connection point with the surface.

One of Magics 23’s key updates is greater control over how support structures are built

E-stage for metals integration

Alongside the existing tools for preprocessing, Materialise has also been developing a new set of tools called e-Stage. These package up Materialise’s wealth of knowledge in both software and working as one of Europe’s largest service providers, to provide a set of tools that automate the generation of supports and handle optimisation tasks that would otherwise be performed manually.

In short, e-Stage encapsulates the company’s knowledge as set of tools that allow you to get up and running quickly.

Initially, this was focused on SLA part processing, but with Materialise Magics 23, Materialise has introduced a set of tools for metal parts, too. Here, the process is based on the material you’re using, with built-in best practices for that material and your chosen process.

For example, if you’re working with aluminum parts, you’ll want narrower support beams, while titanium will require beefed-up supports.

The key addition in e-Stage is the degree to which you can edit your workflow. With previous versions of e-Stage and Magics, it was a ‘one shot and done’ process. If you wanted to make edits, you needed to delete them and start again.

With the new e-Stage version fully integrated into Magics, you work in a linear workflow, as detailed below, but you can also step back and make edits to contact points, supports or anything else. You begin with finding points on your model that need support and then generate the connections between these and both the base plate and other features on the model. All this information remains editable at all times. On its own, this makes huge sense. And when you factor in the next set of tools we’ll discuss, it makes for a compelling and complete process.

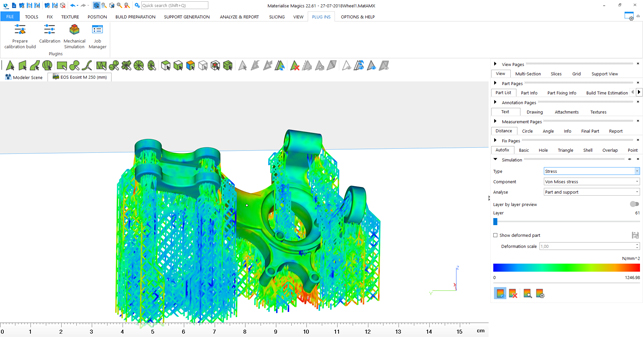

Additive & simulation in Materialise Magics 23

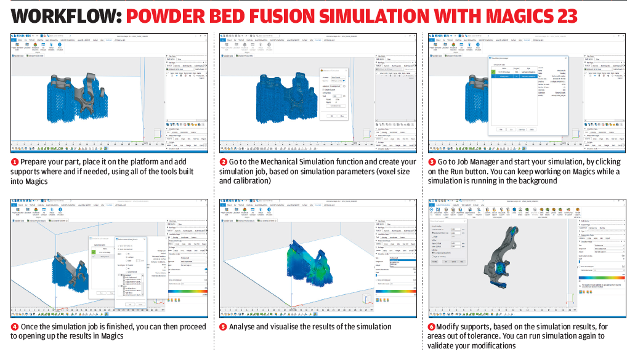

This is another area that’s been added for Magics 23. Materialise has developed, via a collaboration with Simufact Additive (a MSC Software company), a voxel-based simulation solution for metals that simulates the process of building your model, layer by layer, focusing on the risks of build failure and how the shape of your part is influenced over the course of the build.

The voxel model itself can be pretty coarse, but the benefit of this is that it can compute very efficiently on your workstation. The data from this voxel model can then be applied to your higher resolution 3D model.

These tools not only give you a lot of feedback about your model and the build process, but also help you to first understand any issues that might occur and enable you to preemptively deal with them.

A good example here, in the use of metal powder-bed systems, is the risk of recoater crashes. As your parts build, there could be deformation on a localised basis or across the whole part as it builds up, leading to a vertical displacement of solidified material that crashes with your recoater mechanism. Magics will let you simulate the job, find any potential areas of risk, then deal with them, either by reorientation of the part, some redesign work or an improved support strategy, in order to mitigate the build failure risks.

Another interesting set of data is focused on identifying the risk of shrink lines. Just as in moulding, shrink lines in the additive world occur where you have two bodies of near solid material meeting as the part’s production progresses. It is important to note that these simulation tools are, at the present time, specifically focused on the deformation of a part while it is in situ on the build plate with its supports intact.

It’s also possible to predict deformation once a part is separated from the build plate and its support structure removed.

But, for now, Materialise Magics does not take into account the order of support removal, nor any potential heat treatment step, both of which can also influence part deformation.

Magics 23 sees the introduction of Materialise’s metals additive simulation tools, allowing you to see how your part will form (and deform) during the build process

In conclusion

Materialise Magics has been on the market for a good long while now, driven by Materialise’s knowledge and best practice, gained over decades of providing clients with huge volumes of additively manufactured parts using almost every process under the sun.

As it stands, Magics is a modular software package, which benefits customers in a number of ways. All of the core functions for part import, repair and processing are there and grow with each release.

Then you start to move into the specifics, and this is where the modular nature really pays off. If you’ve just invested in a polymer sintering machine, you can add the module to help there. If you’re just starting out in the world of metals 3D printing, then there is a rapidly maturing set of tools that will help you get up to speed more quickly in this area, too.

Of course, most machines come with their own set-up software, but if you’re running multiple processes, then having a centralised, common set of tools makes huge sense.

Then there are the efficiencies that you can gain from a system like Magics. While I’m never a fan of quoting a vendor’s statistics about time savings, in this case, these are pretty valid. Materialise has calculated that investments made in nailing your part set-up can gain you some serious benefits after the parts are built.

These include reduced post-processing (thanks to more intelligent support design) and material savings (particularly when it comes to powder-based systems).

If you’re at the higher end of additive, either in terms of technology adoption or volume, then a system like Materialise Magics has some clear benefits over using different systems for every machine or process.

| Product | Magics 23 |

|---|---|

| Company name | Materialise |

| Price | on application |