InfiPoints – Having mastered the world of CAD data translation, Elysium has turned its attention to the processing of large-scale, complex point cloud data. We take a look at how InfiPoints fits into the reverse engineering workflow

When it comes to the world of reverse engineering, there are two typical workflows. One focuses on the capture of an existing object or structure for use as part of a product design process, whether that’s to assist with form and fit, or to capture the functionality of objects to which more mechanical objects need to interface. Then there’s the use of the same technologies to capture much larger objects, whether that’s a factory, a building or a bridge, either during construction or for a retrofit of a plant or equipment.

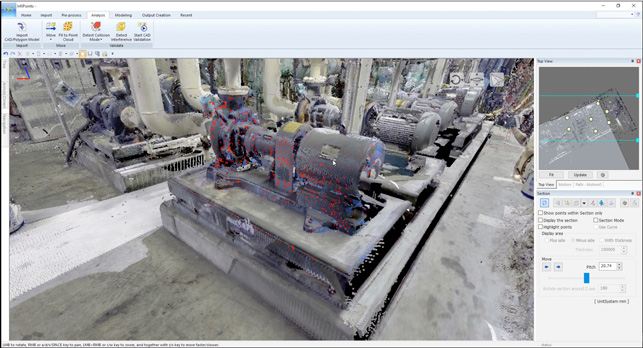

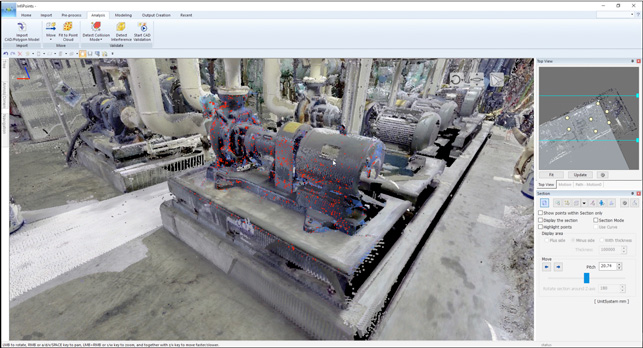

InfiPoints allows you to register together multiple scans using a wide variety of methods

Both workflows have specific, individual requirements. The first workflow might be to generate accurate, analytic surfaces on top of point clouds. The second, which InfiPoints addresses, focuses on the extraction of data from much larger datasets; for example, documenting P&ID pipe and duct work on an oil rig or the movement of large-scale plant machinery within an existing factory.

InfiPoints – data import/pre-processing

InfiPoints is built to work predominantly with static laser LiDAR-type scanning devices, as opposed to handheld devices from the likes of Creaform and Artec3D. That said, alongside support for the likes of Faro, Leica, Pentax Topcon and Zoller+Fröhlich, it also now supports data from Dot Products’ handheld devices.

What’s key to realise from the outset is that this is a system built to handle massive datasets compared to many older tools.

Here, we’re talking billions of points and hundreds of gigabytes of data. InfiPoints is centred on a rendering engine that allows the user to handle these huge quantities of data without too many restrictions.

Of course, with static scanners, the process of registration and the merging of multiple scan sets is fundamental. InfiPoints supports most of the common workflows: automatic recognition of reference spheres or checker boards; using coordinate references; and using automatic recognition of planar shapes for those scans where targets just aren’t possible.

With InfiPoint’s support for static scanners and its early explorations of integration with handheld devices, static scanners can be used for larger scale scans, while handheld devices can be used to capture finer detail, where required.

Once your scan sets are registered together to create a complete visualisation of your job, the next step is to remove any noise. This can be caused by overlapping of scanning sessions, for example, or movement of items within your job during scanning.

Here, InfiPoint’s automated tools can quickly identify any items that have moved during the scans (whether that’s a human body, a vehicle or a piece of factory equipment) and remove them.

For those looking to use such technologies in busy environments such as warehouses, shopfloors or public areas, this could be a real time-saver, allowing work in that area to continue while you conduct your scans and thus minimising downtime.

A final aspect to consider on the preprocessing front is the need to reduce data size. While InfiPoints is able to handle huge datasets, it may be the case that you want to use the output in other systems and thus need to create lighter weight, point-based representations. The system includes tools to do this, using an intelligent process that reduces the weight of your point cloud without altering its accuracy.

InfiPoints – geometry wrangling

The next stage in the InfiPoints workflow depends entirely on your requirements. It could be that you’re simply looking to bring together scan data, perhaps from a variety of scanners used on-site. Or perhaps you want to be able to view, prepare and inspect your point cloud data and need a non-partisan solution to do that.

All of this is possible with this system, but the real power of InfiPoints comes to the fore when you start to extract objects to create more usable data.

The system includes a range of feature extraction tools that allow you to add in ‘proper’ geometry (compared to pure points) for items such as pipework, ground planes/floors and such.

First, this will allow you to take more accurate measurements, as you’re taking dimensions, for example, between the centre or exterior of a pipe and a floor, rather than trying to select an individual point.

Second, there are some interesting workflows around exporting this data (for pipework in particular) to your CAD system.

The system includes a range of tools for completing any missing information (for example, joining together disconnected pipe definitions or adding in standardised fittings), before you start to export the data.

When it comes to the export itself, Elysium’s background in and mastery of data translation stands out. The product has some rock solid translators built in, in order to move data to your CAD system. It includes translators for the majority of systems out there, from Inventor and SolidWorks to Catia and NX, as well as a range of BIM solutions.

As well as extracting CAD-style data from point clouds, there are also tools within the system to create (and use) polygon-based models, either of your scan as a whole or smaller portions of it.

It might be that you want to capture the form of some items of plant equipment, for example. You might not need a full conversion to solid or surface geometry, but having a polygon mesh-based representation would be useful. InfiPoints allows you to select the points you want to use, extract them from the larger scan set and then create a mesh-based model.

That could then be used as a reference for further modelling work, for archiving or for downstream processes and analysis, which we talk about next.

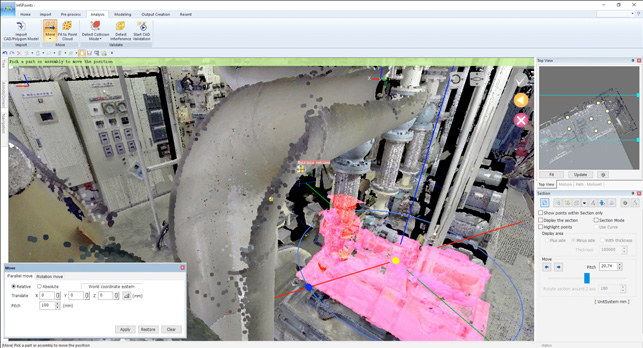

InfiPoints allows you to extract data and use this as the basis for collision detection. Need to shift that 5-axis vertical mill? Let’s see if it’ll fit through the door

Infipoints – analysis

Alongside the use cases we have already discussed, there’s another area in which InfiPoints has some interesting tools and capability. In addition to the standard measurement tools, you’re also able to conduct collision detection within your point cloud data, which is useful for a couple of workflows.

Imagine, for example, you need to shift a large item of plant out of your factory or move it to another position in order to reconfigure your production line. InfiPoints allows you to quickly identify the geometry relating to that piece of plant and use this as the basis for collision detection.

You can experiment with moving it out of the position, through your facility and into its new position, either using a prescribed path or freehanding it. The system will work with an assigned tolerance, depending on how close you want to run things, and show where you could come unstuck.

The reverse is also possible. Imagine a crowded shopfloor, where you intend to bring in a new machining centre. If you can squeeze that centre into the required position, downtime is minimised.

InfiPoints, with its data translation abilities, allows you to read in CAD geometry from a variety of formats, so you could bring in a model (or indeed a scan set) of your new 5-axis machine tool and see if you can manoeuvre it into position.

Alongside collision detection, another big use case for InfiPoints is as-built validation, between the ideal represented in a CAD model of your facility and the reality as captured with your scanners.

InfiPoints includes tools that allow you to compare your point cloud against either your extracted surfaces (perhaps to show wear) or to import a CAD model against which to base your comparison.

This allows you to capture any undocumented changes in your CAD model, perhaps document construction progress or find any anomalies, in either your physical world or your digital one, before embarking on new projects.

Viewing, collaboration & VR

To round things out, let’s talk about how InfiPoints allows you to share and interact with your large-scale scan data. In the first instance, Elysium has developed a method of creating a lightweight representation of your model that can also contain notes, markup and any hyperlinked files, along with a freely distributable viewer application.

This makes it ideal for for collaboration or, indeed, rich work instructions. While I’ve used the term ‘lightweight’, it is worth noting that we’re talking about the reduction of data from hundreds of gigabytes down to a couple or so. In other words, lightweight is all relative.

If you need to communicate your data with non-technical folks, another option is the creation of fly-through videos. These can be quickly created by identifying the required viewpoints and having the system move between them to generate a video.

Another recent innovation is Elysium’s addition of VR support to its toolset. In this way, you can immerse yourself in your dataset at real scale, rather than via a small desktop monitor, which gives you a true appreciation of scale when needed.

At the moment, the InfiPoints for Oculus capability allows you to navigate your datasets, conduct design review (with simultaneous access for multiple headsets), take measurements and more.

In conclusion

Elysium’s history in data translation really starts to show as you dig into what InfoPoints can do. InfiPoints allows you to read in and work with a wide range of data from both today’s range of advanced 3D scanners and from your workhorse CAD tool.

This, in turn, enables you to carry out key workflows using data from this wide variety of sources, so that you can not only capture form on a large scale, but also carry out meaningful tasks, whether that’s creation of CAD data from point clouds, measurement and markup, collision detection or collaboration.

If you’re looking to document progress of a construction project compared to the ideal CAD models, or to evaluate the process of retrofitting new machine tools on your shopfloor, or to reconfigure an assembly line, it’s all there in InfiPoints, with the tools to read and write data in the format you need it.

| Product | InfiPoints |

|---|---|

| Company name | Elysium |

| Price | on application |