Fusion 360 – We take a look at what’s been done in the system over the last year or so and find a set of technologies that has been through a maturity cycle

Autodesk Fusion 360 has, in its current guise, been on the market for three years as a ‘released product’. And while the core of this CAD/CAM software tool started out as a cloud-based design, it quickly became apparent that Autodesk harbours much bigger ambitions for it.

Today, Fusion 360 includes not only solid and surface modelling capabilities (in both history and direct edit modes), but also incorporates the t-splines technology, which Autodesk acquired a few years ago.

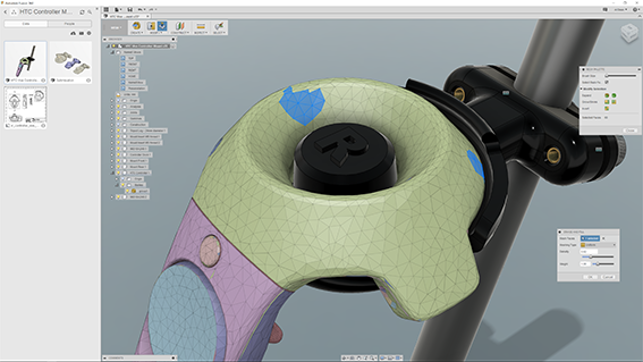

Fusion’s new Mesh Workspace gives you tools to rework mesh data, with some fancy tools for remeshing, repairing and converting geometry

This technology enables sub division like modelling of complex, organic shapes with recourse to traditional surface modelling techniques.

Alongside the geometry creation tools, there’s also been a lot of effort expended to add in simulation (primarily structural at the moment) as well as to bring online some of Autodesk’s HSM technology (CAM software that it acquired from HSMWorks in 2012) for programming machine toolpaths.

Fusion 360 is cloud-based and while, at present, the system only works in a ‘local client synchronised to cloud server’ manner, the backbone of that is Autodesk’s all-encompassing A360 platform. That means there’s potential for web-based collaboration with partners and suppliers where projects are synchronised to all participants and access is open.

However, at present, this doesn’t really support the inclusion of non-critical partners — it’ll need more rigorous access controls over and above the Read/Write/View locks already in place.

So where are we at with Fusion? The last time we looked at the system Autodesk had just introduced simulation tools and had started to introduce CAM functionality (predominately 2.5 and 3 axis operations).

It had also embarked on expanding the system’s ability to work with referenced data and manage inter part or assembly model links.

Fusion 360 – Core modelling tools

Let’s look at the core modelling tools, namely, the ability to create both history and direct modelling based product definitions.

Fusion 360 has, in its current guise, included the ability to model with both a full history tracking switched on or to switch it off and go full direct editing.

Your choice between the two depends entirely on the type of job you’re working on and the results required. The good news is that your parts can be switched between the two. Of course, if you switch off history half way through a design, you’ll lose work to date and vice versa if you switch history on in a direct edit part, you’ll only capture operations after the switch.

It’s also worth noting that the system, as you’d expect for a cloud-based system, stores a complete version history of your model, so you can step back to it if you get stuck.

The prismatic modelling tools in Fusion 360 are pretty well advanced and have been for some time. Both the Model and Patch workspaces allow you to work with both solid and surface geometry respectively. In more recent updates (and if you’ve not tried out the system for a while) you’ll notice that there’s been some core work done to make the cross body features more intuitive and controllable (you can now select which bodies an operation effects).

It’s also worth noting that the selection fi lters have been updated and it’s now possible to set not only specific filters (to help select edges, faces, bodies etc.), but also to define a priority during selection, which is particularly useful in more complex models.

Fusion 360 – Mesh repair and repurposing tools

In the last couple of monthly releases, Autodesk has been introducing a ‘Mesh’ workspace.

While Fusion 360 has always allowed you to import and display mesh forms (from OBJ or STL, for instance), the usefulness of that data hasn’t been much beyond pure display. The Mesh workspace changes this and introduces tools that allow you to do more with those increasingly common forms.

To start, you can import the data in a number of ways. There’s the ability to upload data directly to the underlying A360 platform, then insert that geometry into your current product. While the system allows you to view and upload data directly from the mobile app, a more useful method is to use the Insert/Mesh command.

This gets around Fusion 360’s insistence on assuming all non-unit specific geometry is held in centimetres. Now you can not only set the unit but also automatically snap that geometry to the origin, correct the orientation and generally get it in the correct position for your task at hand.

Alongside this, the system includes a number of pretty well developed tools for repairing, remeshing and repurposing that data into a form that’s useful.

Whether that’s smoothing out that mesh, repairing any holes or remeshing the geometry. There’s also a tool to help divide up that mesh into sensible portions by colouring each section and automatically finding changes of curvature (edges etc.), which assists with selection for further operations.

While it’s not quite up to the standard of more reverse engineering focused tools, there’s plenty to go at. One thing that’s worth considering is that you are able to convert that mesh into something that’s more useful in terms of CAD operations.

And although these tools are good they work within specific limits in terms of how many facets you can throw at the conversion process to take it into a t-splines form (which can then be further worked on).

The number that needs to be achieved is around the 10,000 faces mark. While for prismatic parts that’s not too heavy, as soon as you start to work with curved or cylindrical faces, the faceting increases so it’s often difficult to get a decent form while staying under that face count limitation. That said, if possible, you can quickly convert the mesh to t-splines and start to work with it.

If you can’t convert it, the geometry can still be used as reference material, but the ability to do much else with it is limited at present.

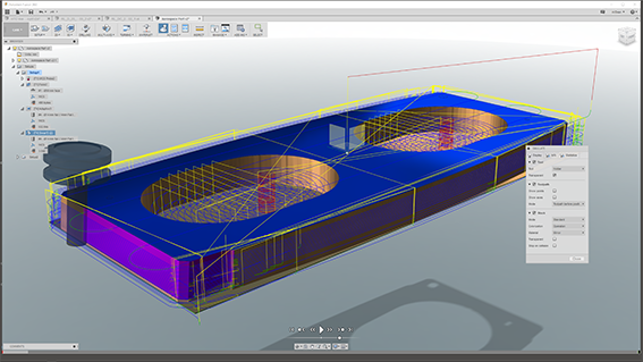

Fusion 360 – CAM workspace

Following our last review of Fusion 360, the team have introduced a number of key tools to bring together the various constituent parts into a more cohesive whole.

For example, while in earlier versions, the tooling library and storage of post processors was pretty adhoc in many places, this has now been fixed. Everything is synchronised as it should be, using the A360 platform to do much of the heavy lift.

Post processors, when stored on the cloud, will follow you wherever you need them and there’s been a lot of work done on the tooling/cutter library to achieve the same.

In terms of operations, there have been consistent upgrades over the last year with many of the operations now gaining greater control over their various options and parameters. Perhaps one of the biggest updates has been the introduction of more advanced machining methods, namely 3+2 positional as well as more simultaneous 5 axis in the most recent major update.

While these tools don’t have the full machine simulation that more costly tools might have, or the fine control and wealth of operation capability that say PowerMill has, the tools are beginning to progress.

For now, you’ve got the ability to define tool orientation (allowing for positional work), as well as two new operations for swarf cutting (where the complete cutter length is used to machine surfaces) and 5 axis profiling, ideal for fi nishing and trimming operations.

Simulation workspace

Perhaps the biggest update this year has been to the simulation toolset.

This was introduced in late 2015, but the whole infrastructure has recently been replaced. Fusion 360 had been using the Plassotech solver, which Autodesk acquired many years ago, but in late 2016 the whole system was swapped out to run on the industry standard Nastran solver, which came with the NEi Nastran acquisition in 2014.

As standard, Fusion 360 is now supplied with four study types; static stress, structural buckling, modal frequencies, thermal and thermal stress. Alongside these, there are also a number of additional studies available including shape optimisation, event simulation and non-linear static stress.

These are categorised as “Preview” studies. To gain access to them, you need to switch them on (you’ll find the toggle under the Preview section of the Preferences panel). These will eventually be included in the newly reintroduced Fusion Ultimate subscription, but for now, you can experiment with them at no additional cost.

The use case for each of these will differ depending on the studies requirements in terms of use and inputs, but at the core, each works in the same way. Your product model can be switched into the Simulation Workspace, then you define each of your studies as you need. Each study has its own entry in the browser listing. There’s been work done to make the reuse of already defi ned inputs and settings between each study possible.

Complete studies can be cloned and adapted or you can copy/paste or drag and drop individual elements between each study, making reuse of data easier and reducing repetition of the same task. You can even drag and drop individual elements (such as load cases or constraints) between studies based on different physics models.

This release also sees some additional tools to help with the study definition process, whether that’s the ability to control and adapt contacts more easily or to define bolted connections. The latter is particularly well thought out, with all the options you’d expect, just as defining the geometry of the hardware options (for washers etc.), pre-loading and such.

There’s also been some work done to give you greater control over mesh construction. While previous releases allowed you to vary a ‘global’ element size, the new tools allow you to highlight areas where you want greater concentration of elements.

Lastly, for simulation, there is the new Compare Workspace. At present, this allows you to compare two or more sets of results from different studies within the same product model (rather than between different products). It also allows you to synchronous views and results plotting and even the scales between the chosen studies.

As a means of carrying out multiple experiments, Fusion is ideal, but with this tool, the workfl ow is extended into making the comparison and decision making based on those experiments much easier.

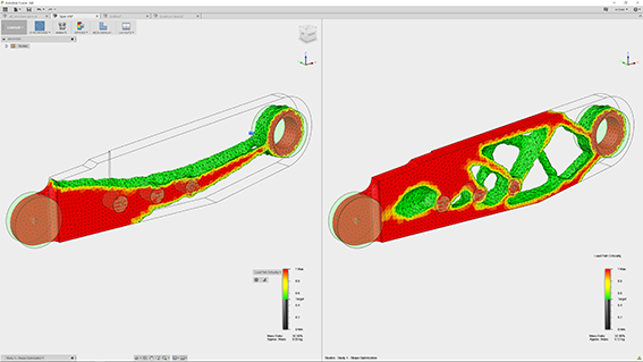

Fusion’s new Compare mode allows you to load up studies in a single design and compare the results with normalised scales and synchronised views

Fusion 360 – Shape optimisation

This is a particularly interesting study as it looks to be a direct translation of the same tools that have been introduced into Inventor in the last year or so.

The workflow is as you might expect. You begin with the part you want to optimise then work through the process of not only defining the loads and constraints on that part, but also the optimisation parameters.

You start the process off by defining any planes of symmetry (this will reduce processing time) then work through defining any regions that need to be protected in terms of the shape reduction/removal process. You do this by snapping a box or cylinder to the geometry in question and dragging it to the shape you want.

Once done, you then need to define the parameters that will drive the optimisation process.

The default is to look for a 30% mass reduction, but this can be adapted to add in other factors, such as factor of safety. When it’s ready (the system includes checks for all study types to make sure you have everything required for it to solve), you submit it to the cloud for processing.

Once the results are back, you pull the results data back and inspect them.

Next steps depend on what you intend to do with those results. You can take the resultant mesh and ‘promote’ it back into the modelling environment — either for processing and tidying up (perhaps using the Mesh workspace) or you can use it as reference for making edits to your ‘proper’ geometry.

Fusion gets more advanced machining updates — including the ability to program simultaneous five axis toolpaths for swarf machining and profile trimming operations

Cloud solve & costs

The above passage introduces something that’ll need to be considered as many of these tools pass from ‘preview’ to being released into the product.

Autodesk is enabling many of these study types as a cloud-only solve. While the existing tools give you the option of solving them either locally (on your local hardware) or in the cloud, these more advanced options will only solve on the cloud. So what does that mean?

The workflow benefits are that you’re offl oading some pretty heavy computation from your workstation to a cloud-based solver. That means that you can get the results done pretty efficiently (though not necessarily any quicker), but more importantly, your workstation isn’t locked up doing the donkey work. When you consider the more iterative nature of some of these advanced studies (such as event simulation and shape optimisation), that makes huge sense.

Also, considering the repetitive nature of many design projects and the experimental phase of engineering, you’re not just looking at a single study, but many of them; 10s, if not 100s in some cases. With these cloud-enabled solves, you can fire off as many as you need, evaluate different materials, loading conditions and design variants — again, without impacting your local workstation.

If you’re iterating a single study, then the good news is that the bulk transfer of data only happens once. Fusion 360 uploads the loading conditions, mesh etc. for the first solve. From that point on, as you make edits and re-compute, the system only transfers the items that have changed.

That all makes sense from a pure workflow point of view — assuming your organisation doesn’t have issues with such data being held on the cloud, it’s very efficient. Where things get more interesting is how these features are priced. As you’d imagine, there’s a cost associated with using someone else’s compute power.

While these cloud-solves are free to use when in preview, once released, this won’t be the case at all, so let’s explore how the costs stack up.

The first to take note of is that each time you use the cloud services from Autodesk, you’re using what’s referred to as Cloud Credits. While what this ‘unit’ represents isn’t too clear, it’s analogous to compute hours that some readers might be familiar with — or how long it spends on the hardware carrying out the computation.

It’s also key to note that if you’re paying for a Fusion Ultimate subscription, you’re looking at either $1,500 per year (or $300 per month). As part of that higher subscription, you receive 1,000 cloud credits. These credits can be used for both rendering and for simulation tasks.

In terms of simulation use, the amount used is variable, depending on the study you’re performing and the complexity of that study. While the tools are in preview, Autodesk has, handily, published a guide to the amount of credits that will be required for each study type — and it makes for interesting reading.

To break it down in simple terms, if you run a cloud-solve for linear static, modal, thermal, thermal stress studies or shape optimisation studies, they’ll use up five credits. If you’re using a buckling study, it’ll cost you 15 credits, while a non-linear static study costs 25. Then if you want to run a Shape Optimisation study, you’re looking at the costs beginning at 15 credits, which will increase depending on the complexity of the study. I’m guessing that this will be based on the number of time steps you set to run with.

Immediate questions should be: what if the solve fails? And what happens if I tweak the settings and run that study again? The simple answer is that each time you complete a solve, the number of credits is removed from your account. If you realise you’ve not defined the materials from whatever is defined in your CAD model, forgotten a load or a constraint or missed a digit, the credits are gone. If the solve fails to complete, you won’t get charged, just as it doesn’t if you cancel it (but you’ll be charged for the percentage of completion).

Looking at this, you’ll realise that, depending on the type of studies you’re conducting, the frequency of use and the complexity of your tasks, you could burn through credits very quickly — 1,000 credits gives you 40 non-linear study computations. That said, each Ultimate licence comes with 1,000 credits when you buy it, so you’ll have a lot to play with, but it is worth considering that if you use up those credits — each costs $1 — and that in turn puts a finite price for each study.

Once your allowance is used up, that’s exactly the amount you’ll be paying for additional credits.

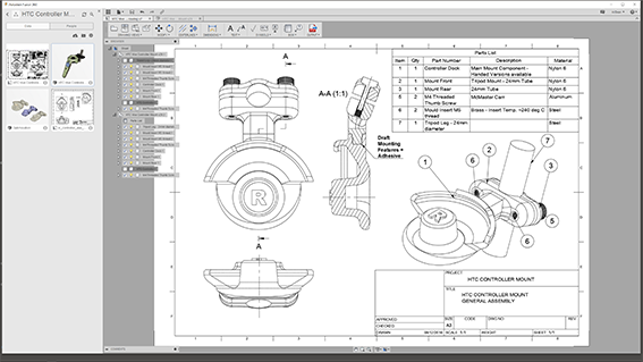

Drawing workspace

Let’s round things out with a look at the Drawings workspace.

This has been in the system for a year or more now and each release brings new tools that are fleshing out the capabilities you need to not only create accurate drawing views, but also to add in those dimensions, tolerances and other annotations that you need to manufacture parts — particularly when dealing with suppliers and contract manufacturers.

The set of tools in Fusion 360 isn’t fully developed, but with each release the process is made more efficient. A good example of this is the ability to take the thread information you’ve already defined in the 3D model and not only display it correctly (particularly in section views), but to also extract the manufacturing information automatically into the annotations you need.

Another solid example is the work done to make it easier to layout drawings the way you want to rather than having to rely on how the system works.

In specifics, it’s now possible to have multiple base views in a single drawing sheet. This will allow you to create assembly based, general arrangement, style views, then add in a view of a specific part for further annotation.

Fusion 360’s drawing workspace has been evolving over the last 12 months, adding more dimensioning and annotation tools as well as greater control over view layout

Conclusion

Fusion 360 is growing in both sophistication of the toolset and the range of capabilities available at an impressive rate.

Consider that just 12 months ago we were looking at a system that covered 3D CAD, basic drawings, 3 axis machining and had only just started to see the introduction of simulation technology.

When we look at it now, the CAD tools are maturing (and these things are never finished) and it now includes complex form description and a good set of drawing tools that is also gaining those finer tools needed to fully document a design for production.

It’s also gained the Nastran solver and will shortly expand the range of simulation capabilities beyond anything that’s available in the same price range. Then you’ve got the full set of machining tools that are now starting to see the support for more complex five axis simultaneous machining.

To introduce that amount of upgrade and enhancement in a single year is incredible.

The fact that it runs across multiple platforms (Windows and OSX) seems to be a big thing for many, as is the ability to store your data centrally and have access to it wherever it’s needed. While, historically, much of the focus has been on the design capabilities, it’s clear that many are adopting Fusion 360 for the design and manufacturing tools.

The fact that you can gain access to an impressive set of design and geometry defi nition tools and advanced high-speed machining, starting at $40 a month (or $300 per year), is making many question their existing software suites.

And while it’s still early days for the Nastran-based simulation technology, I’m expecting that the same will happen for those looking for advanced simulation capabilities. After all, above everything else, the ability to run advanced nonlinear and shape optimisation tasks is something that many are looking to and even with the higher cost of the Fusion Ultimate subscription (at $190 a month/$1,500 per year) and the additional credits you might require, it’s still signifi cantly cheaper than running a more traditional licence of Nastran from other vendors.

Click here to read what Autodesk is discussing for the next year or so. Sheet metal will be key for many as will the electronics interchange tools. The additive manufacturing tools, while applicable right now, to a much smaller percentage of the market than the machining tools, give you an idea of what’s coming and how you might be able to make use of them.

Fusion + Nastran: Why is it such a big deal?

While there’s been an extension of the types of simulation tasks you can perform with Fusion 360 for this release (albeit in Preview mode for now), perhaps the biggest news is that the team has swapped out the simulation technology.

While the simulation tools within Fusion have been based on the Plassotech solver that Autodesk acquired over a decade ago, from this point onwards the tools are built on Nastran.

Let’s just consider that for a moment. Fusion now has all of its simulation tools, that cover the spread from linear static problems, through thermal and electro mechanical simulation and now into the realms of non-linear simulation, all based on Nastran. If you’re deep into simulation you’ll realise what that means — if not, perhaps some explanation is necessary.

When it comes to solver codes for simulation there is a wide choice, but as soon as you start to look at industry acceptance, then you’ll find that the simulation solver technology narrows somewhat. If you then filter things down to both linear and non-linear structural simulation (which represents a fair proportion of all simulation jobs), then you’ll find that both Ansys, Abaqus and Nastran are the front runners.

What’s interesting about Nastran is that the code is a lot more open than most. Because it was developed by NASA, the code is available, at a very core level, to anyone that wants it – that means there are several branches available.

In the commercial space, this comes down to three; MSC has its branch, Siemens PLM has its NX Nastran branch and Autodesk has its own branch as a result of the acquisition of NEi Software a few years ago. Why is this a big deal?

The answer is simple. Nastran-based solver codes are accepted in many industries (such as Automotive and aerospace) – they’ve been benchmarked, tested, compared against physical test results and made use of for decades. If you’ve got a Nastran branch in your system, then the simulation door is open in many organisations, and this is key, those organisations aren’t messing around.

Autodesk hasn’t sidestepped the issue of benchmarking and acceptance, but it has managed to get a head start. By making Nastran available, at a price that, to be utterly frank, is ridiculously cheap compared to other commercial codes out there, it stands to gain some pretty heavy attention from the simulation community.

Learning Fusion

Everyone likes a bit of training to help them get up to speed with a new software tool. But if you’re purchasing the system over the web and not through a reseller there’s not much in the way of formal, classroom based learning.

While Autodesk provides tutorial videos and online support, if you’re looking for something more formal, then you’re out of luck. Or are you?

There are a number of online training providers – most of us are familiar with Microsoft/Linkedin owned Lynda.com – which is branching out into providing the same level of learning resources for CAD systems as it does for the likes of Adobe Creative Suite. It has a couple of courses for Fusion 360 and subscriptions are £12.95 a month.

Another company that’s providing online learning tools for Fusion 360 is PluralSight ). Again, its business model is one of ‘all you can eat’ subscriptions (starting at $29 per month).

There is one thing worth noting though: both Lynda.com and PluralSight work like many services, in that you need to add in your credit card details before you gain access to the trial and you’ll be charged once it ends.

| Product | Fusion 360 |

|---|---|

| Company name | Autodesk |

| Price | $30 per month |