From the outside, Design Q’s premises on an industrial estate in Redditch, Worcestershire look deceptively poky. Step inside, however, and the design consultancy’s Tardis-like workshop extends over 10,000 square feet of floorspace – enough room, it turns out, to house a full-size aircraft mock-up, laid out in two 60-foot sections.

Thanks to UK-based consultancy Design Q, the Bombardier Global 7000 jet looks just as good inside as it does from outside

It’s here that the Bombardier Global 7000 prototype, which the aircraft manufacturer claims is the largest marketing mock-up in business aviation history, spent five months while its interior was being fitted out.

Creating the slick, contemporary interior design was Design Q’s most ambitious project to date. The company was established in 1997 by Howard Guy and Gary Doy, both former principal designers at Jaguar Cars. Their initial focus was on automotive projects, but within a year, commissions were coming in from the aircraft industry. These included a four-year contract with Virgin Atlantic, which saw Guy and Doy working with the airline’s in-house design team on the acclaimed Upper Class seat.

Eighteen years on, the company’s project portfolio has continued to expand, along with its design and engineering skills. In aviation, it has designed a number of luxury aircraft interiors, including ABJ Fusion for BAE Systems and Challenger 350 for Bombardier. In automotive, it’s created both interior and exterior designs for models including the Jaguar F-Type 4-door coupe, the Range Rover Q Commander and the Maserati 4200 GranSport.

Design Q was commissioned by Bombardier to create an interior for the Global 7000 business jet that offered passengers “total luxury and refinement”

While its main focus is on concept development and the creation of prototypes for aircraft mock-ups and show cars, Design Q can, where required, take projects right through to production. One example is the lightweight PF2000 fixed-recline seat, created for Pitch Aircraft Seating Systems and now installed across Monarch Airlines’ UK-based fleet.

At the same time, the company can also deliver one-off, bespoke vehicle projects, such as the dramatic facelift it recently gave an 11-year-old Maserati 4200 Spyder.

“We do all sorts and we are always into doing new things. That’s the beauty of consultancy: you’re not always working on the same stuff,” says Greg Shilton, Design Q’s design manager.

His colleague, designer Robert Morton agrees, adding, “In one day, I can work on a car, a business aircraft, a commercial aircraft and a show stand for an exhibition. The variety for me is the great thing and, because of this variety,other projects, sometimes in a different industry.”

The Global 7000 aircraft offers four distinct living spaces, including a private stateroom where passengers can relax, sleep and refresh

Longstanding partners

Design Q has worked with Bombardier Aerospace regularly over the past eight years on a variety of projects. The relationship kicked off back in 2007, when the consultancy designed a brand-new concept interior for Bombardier’s Global Vision flight deck, which was released at that year’s National Business Aviation Association (NBAA) show in Atlanta, Georgia.

This initial concept-styling exercise progressed to a full surface development, on which the Design Q team worked closely with Bombardier’s own engineers and integration team in Quebec, Canada. Following the success of that project, the team was subsequently invited to participate in the LearJet 85 and Bombardier Challenger 350 interior design projects.

Meanwhile, in the background, the in-house design team at Bombardier was continuing to work on its Global Vision interior concept, with a view to adapting it for the airline’s new Global 7000 luxury business jet aircraft.

“They got to a stage in their development where they wanted to produce a full-scale mock-up of this aircraft to show customers how they could be flying in three to four years’ time,” Shilton explains.

That led the aircraft manufacturer to once again approach Design Q in June 2013, this time with the brief of resolving the Global 7000 concept design and working with it to produce a full-size prototype of the interior. This would incorporate four distinct luxury living spaces, including a private stateroom, and would be showcased at the European Business Aviation Conference and Exhibition (EBACE), scheduled to take place in Geneva in May 2014.

When the Bombardier Global 7000 mock-up arrived at Design Q’s offices, it was all hands on deck to get it ready for the EBACE 2014 show in Geneva

With less than a year to go until the project’s delivery deadline, time was of the essence. This was to be the largest marketing mock-up that Design Q had ever worked on – but as the project kicked off, it was still 5,000 miles away at a Bombardier manufacturing plant in California.

Rather than wait for the mock-up to arrive in Redditch, the Design Q team instead used CAD data of the fuselage in order to get straight to work on producing parts.

“By sharing the CAD data, we made a section of it and, using that, we were able to work out the fixing and holding of things and the gap conditions between different parts. So it was a way of cutting the programme [time],” Morton explains.

But, Shilton adds: “We had to get the CAD model defined to a good level, so that as soon as the fuselage came, we could fit out the entire thing.”

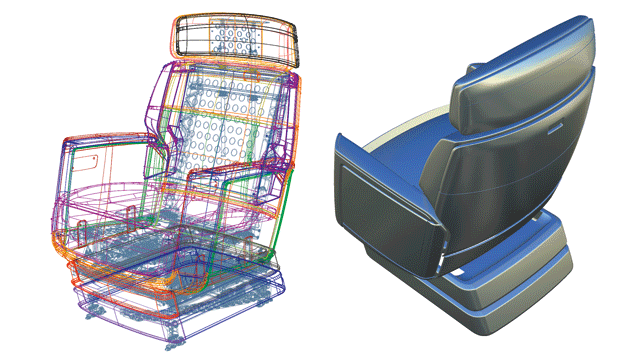

This was a big challenge, because everything in the Global 7000 interior was to be made entirely from scratch. The seating alone required a substantial amount of work, given that the aircraft interior would include three versions of the same seat.

“We received a surface model from Bombardier of how they’d like the seats to look. We also received the frame data from the supplier, [showing] where they were in the development of the frame, which was due to be delivered a few months later,” Morton says.

The designers used that information to work out the different mouldings and forms required, as well as how thick the foam needed to be in certain areas. They also had to figure out how to make smaller parts that would be easier to trim and how to bring those together in order to assemble the complete seat.

“For the trimming, we actually worked with a company very experienced in trimming automotive seats, to gain their knowledge about the easiest, quickest and tidiest means to do this,” says Morton.

The seats also featured metal parts such as pull levers, bezels and badges, which all had to be machined out, polished and chromed before they could be fitted.

The idea to use metal work came from Design Q’s previous work on the Bombardier Challenger 350 project, which incorporated manufacturing techniques derived from the automotive industry. While the team at Bombardier was happy to use painted foam parts in the marketing prototype, Design Q was convinced it could produce more representative, but lighter weight, metal parts.

In the Bombardier Global 7000 project, the seating design alone required a fair amount of work in CAD

“It’s funny, because the process of pressing stainless steel parts is not a new technology, but there is a lot less of it now that automotive manufacturing has virtually disappeared from the Midlands. We use a company in Coventry that has large presses capable of producing these thin-wall stainless steel parts,” Shilton explains.

“When we showed Bombardier these metal prototype parts versus their foam ones, they couldn’t believe that they were indeed lighter, not to mention stronger and more durable,” he adds.

As well as outsourcing the production of some parts, Design Q also built others in-house, utilising the skills of its craftsmen, which include old-school pattern-making expertise.

“We could spend hours on the CAD system – or we can walk down to the workshop and find that [our craftsmen] will have a quicker and easier way of doing it, because they have done something similar in the past. Their knowledge and skills are invaluable,” says Morton.

International exposure

In December 2013, the Bombardier Global 7000 fuselage arrived at Design Q’s workshop on two articulated lorries, having completed its long journey from California to the West Midlands. With just five months left to go until EBACE 2014, it was all hands on deck to get the mock-up fitted out in time.

A final, concerted push did the trick, with the interior finished to a very high level of detail, complete with polished and brushed metals, stone work tops, hardwood floors, satin gloss wood veneers and silk carpets.

The 120-foot long, 54-tonne mock-up also features an electrical system not too dissimilar from a real aircraft and includes about 25 miles of cable.

Once complete, the mock-up was loaded back onto the lorries in order to make its way to Geneva for the launch of EBACE 2014. Although this was by far the largest and most ambitious marketing prototype that Bombardier had ever showcased, its aspirations were handsomely rewarded at the show. EBACE visitors were impressed when they stepped on board. Some even placed orders during the three-day event.

The mock-up appeared once again at EBACE 2015 and, from there, set out on a round-the-world tour, taking in aircraft shows in Dubai and China, as well as being shown to individual customers at private viewings. In November, it will be on display at the NBAA 2015 show in Las Vegas.

For a small company like Design Q, this was a very large project and one of which the team is justifiably proud.

“For me, certainly the buzz of what we do is that you start with nothing and end up with something that is pretty outstanding,” comments Shilton.

“You can only get there because of the team you are working with and the sense of achievement that you get is immense, really.”

The Design Q toolkit

All projects at Design Q start by putting pen to paper, according to design manager Greg Shilton.

“The quickest way to generate ideas is through sketching,” he says. “You always hear of paperless offices, but it’s such a myth in a design studio. No matter how advanced CAD software becomes, unless it becomes so advanced that it can just see what’s in your head, the only way to get an idea out of your head is to draw it.”

That said, work with CAD begins soon after, with the team using a variety of programmes, depending on the strengths of a particular tool or, in some cases, the software that a client uses.

For instance, aircraft clients will predominantly supply data for an airframe, into which an interior design will be built, in Catia. But Design Q also has seats of Alias and ICEM Surf, which are mostly used for surfacing, and of SolidWorks and Rhino, for the main CAD workflow.

“Rhino is really good for packaging. I use it a lot, because I can quickly see if things will fit, whereas if I were to use the more complex CAD programmes, I’d spend a long time actually setting the file up,” explains designer Robert Morton.

“But that’s also the good thing about having a design team of mixed abilities who use different software. If one person is struggling in a certain area, then you can all come together in a room, take a look and offer ways of trying it in a different software.”

“I don’t think there is one programme that would enable you to do a whole project from start to finish, as there will always be some compromise. Having a mix of tools is good,” he adds.

In most cases, the team aim to provide three themes to the client, based on their brief. By the time the client sees these, they’re pretty far developed in CAD and all feasible from a concept point of view.

In order to help the client decide on a particular theme, visualisation tools are used to produce photorealistic renderings. Again, Design Q has a number of tools in its arsenal, including the Autodesk programmes Maya, 3ds Max and VRED. The last of these is a relative newcomer to Design Q, but the team is already seeing some good results from using it.

Revamping a Maserati 4200 Spyder

Design Q director Howard Guy recently received a phone call from the owner of a Maserati 4200 Spyder who wanted his vehicle transformed into something unique.

It was, says Guy, “one of those calls you remember. I was buzzing by the end of the conversation.”

“[The owner has] had the Maserati for 11 years and it’s clearly still a big passion of his,” he continues. “He loves the car and yet told me he wanted something the same, but different. [Creating] ‘the same but different’ is always tricky.”

The process started with a full 3D scan of the car, including all its parts, which allowed the Design Q team to map not only the top surface but also the integral bodywork underneath. Using this 3D data, the team then began designing on top of it, like an overlay.

“The art is to get your sketches to match exactly to the real thing,” says Guy.

The existing front and rear bumpers, along with the side sills, were cut, adapted and remoulded with clay in order to create a more contemporary aesthetic.

“This is done by taking a fiberglass mould from the clay. We then clean up the mould and laminate a glass fibre component from it, which becomes the final part,” explains Guy.

The design team then completed the CAD model, which was used to produce parts for the interior, including new seats and an updated dashboard, as well as for the exterior, including rear tail lights that span the full width of the car and carbon fibre fairings that are mounted behind the headrest.

After a splash of paint, the revamped Spyder was ready to hit the road. “The car really is a work of art, the same but different – oh, so different! And we love it,” smiles Guy.

How Design Q created the interior of the Bombardier Global 7000 jet

Default