Imagine for a moment you’re a billionaire; you may decide to splash out on a superyacht. The newly launched Sunseeker 155 perhaps.

A luxurious floating home over three decks that will set you back a cool few million. You can invite eleven of your closest friends onboard, who will be waited on by ten crew members, as you cruise around the Med.

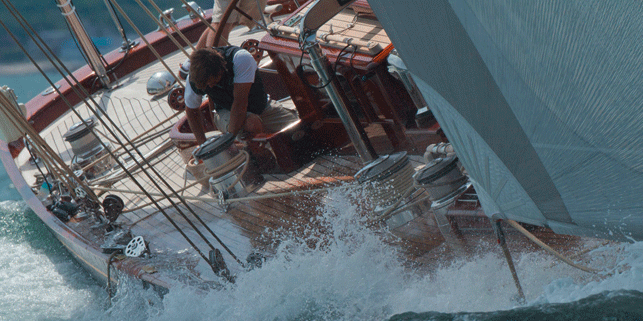

Of course, you’d want your new yacht to be fitted out with all the latest kit. This is where Lewmar steps in. A marine equipment supplier, Lewmar designs, manufactures and tests control solutions for both sail and power boats.

However, a 155 foot Sunseeker is not the biggest boat Lewmar supplies equipment for as its kit can be found on 20 foot fishing boats all the way through to a 250 foot mega-yacht. In fact, it’s currently working on a sail boat that is 335 foot (that is essentially the size of a rugby pitch).

Ship ahoy

Established by Len Lewery and Leslie Marsh in 1950, Lewmar has transformed dramatically from a small company making dinghy products to a large global brand of around 240 people supplying a broad product range to some of the world’s largest OEM boatbuilders including Sunseeker, Princess, Beneteau, Bavaria, Dufour and Hanse.

This range includes hardware, winches, hydraulics, windlasses, anchors, thrusters, steering systems, hatches and portlights, which are sold through a worldwide network of agents and distributors.

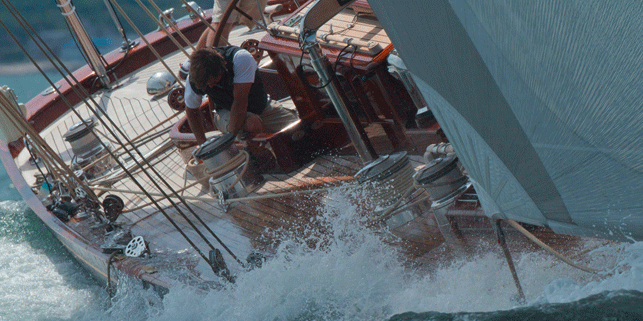

A custom portlight created for Sunseeker which is now part of Lewmar’s range

In 2008, in response to the global economic downturn, Lewmar underwent a restructuring under its new MD Peter Tierney, part of which was to hire a new head of design who could bring fresh ideas and lead the development of innovative products in the hope that it would pay dividends and increase turnover.

Change on the horizon

In March 2012, Nigel Smith was hired as head of design with overall responsibility for product design, engineering and future product platforms. He came from Spinlock – an Isle of Wight-based manufacturer of marine hardware renowned for its innovative and design-led products, where he had been the design manager of a small team for seven years. Previous to that he’d worked within senior design roles at leading design consultancies including Seymour Powell and London Associates.

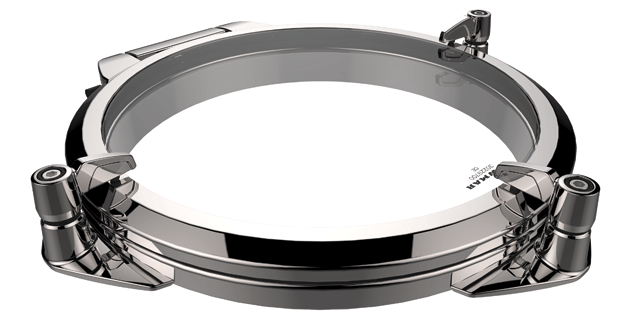

The captive reel windlass CRW400 for small boats up to 30 foot

“The design team just weren’t doing things in the right order,” says Smith. “So, in the two and a half years I’ve been here we’ve put it all back in place in terms of how you run a project and the gates that you go through, just like a design consultancy would.”

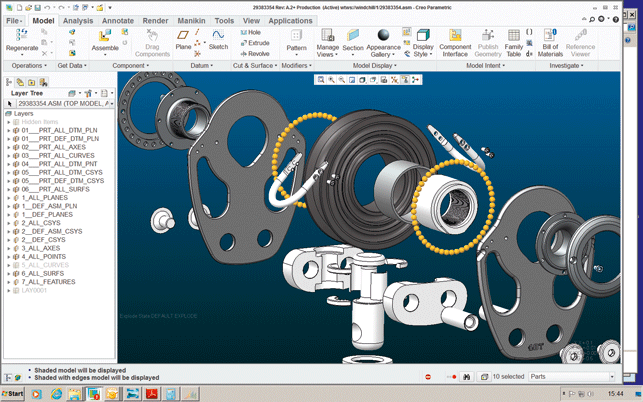

The design team now consists of 15 designers and everything is designed from scratch in-house using PTC Creo2 and SolidWorks.

A typical design process often sees the designers going straight into CAD or perhaps doing a bit of sketching first depending on whether it’s a new product or a product refresh.

A CAD assembly of a control block, part of the hardware range

“It’s at this point we’ll be investigating as a team via Phil Roberts, Lewmar’s engineering manager, likely production costs to build up a picture of what this new product is going to be,” describes Smith.

From there, a prototype will be made by either knocking something up in the workshop, sending the CAD data to the 3D printer or, if a more sophisticated model is required, using a bureau service.

Then and now

As Roberts has been with the company for over 28 years, he knows that things weren’t always done this way.

“In the time I’ve been here, you’d have an idea for a product and draw it on paper. You then may make the parts and start to work out the costs.

That process could take quite some time.

“But now you can have an idea, draw it on CAD, print off a 3D model, use a spreadsheet to work out the costs and do that in a couple of weeks. You’d then know whether or not to take it to the next stage. In the early days, you were almost committed to going towards the next stage and putting it into the marketplace hoping that it would sell. Whereas now you can cut out a lot of the pitfalls before you get there,” explains Roberts.

Lewmar products come online from three main areas. Firstly, from within the design team who have ideas for new products. Secondly, existing products are evolved to make them more aesthetically pleasing, incorporate new materials or to make them more cost effective and, thirdly, a request from a customer himself.

An example of a product that stemmed from a designer having a new idea is the CRW400 – the captive reel windlass for small boats up to 30 foot. This product, which essentially stows the rope neatly on a drum inside an ABS enclosure when the anchor is pulled in, was inspired by a previous product.

“One of our custom products for a big yacht has a line lay mechanism that features a very expensive way of laying the line onto the drum. So we were looking at a cheaper way of doing this and started building some models. When we saw these models we thought there may be a market for a smaller product,” explains Smith.

Built around a stainless steel chassis with Lewmar’s ‘level wind’ technology, the rope is always stowed neatly on the drum. “What it does is pull the line up and there are various mechanisms that lay the line onto the drum so that it doesn’t bunch up,” he says.

The CRW400 was nominated for a DAME Design Award 2013 – an annual award held during the Marine Equipment Trade Show (METS), which takes place each November in Amsterdam. “We launched the product last November at METs and it’s now starting to ramp up. We are currently on 1000 sales,” comments Smith.

Product redesign

The second type of product is the evolution of existing products.

“Although our NPD team are working on brand new products, with many of the products in our catalogue they have been around a long time. In a product redesign, the clever things we’ll be doing is looking at how to manufacture or assemble the product in a different way, new materials become available as well as new product styles and trends,” says Smith.

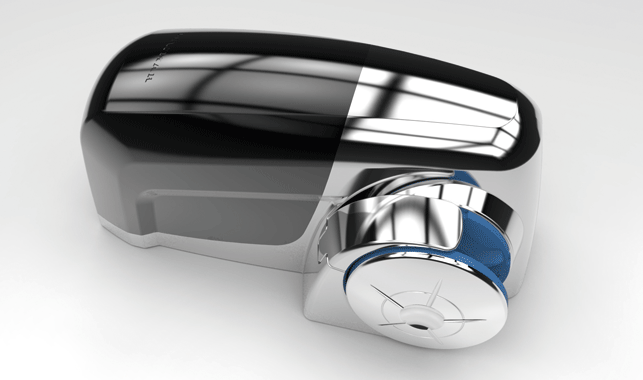

Many boatbuilders are building modern, sleek boats and want modern, sleek solutions to kit them out with. The previous thruster controller, a remote control on the deck that operates a thruster that pops out of the bottom of the boat when it comes to dock, featured a joystick. This has now been replaced with a more modern computer mouse-type operation with an ergonomic pad.

The new range of thruster controls feature a more modern aesthetic

Products are also redesigned to reduce costs, after all, Lewmar has many competitors. “The sales guys will say that a competitor product is cheaper so we have to go through all the costs for that product and then almost design it again to get the costs down.

“So obviously you have to be clever with the amount of material you use. That is where CAD is helpful as it gives you weight, surface area and wall thicknesses. Then you can do some finite element analysis (FEA) to know whether you’ve gone too skinny with the walls. That is a good process to help get costs out,” explains Roberts.

Customer is king

The third area where new products come from is customer requests. This is the result of designers working very closely with many of the boat builders in the early design stages, sometimes, as in the case of Sunseeker and Princess, actually sat within their design offices.

Lewmar will share its CAD library with the boat builders enabling them to easily fit Lewmar’s kit into their boat plan. Or, they’ll send their boat plan to Lewmar, who will place its products into the boat or design custom products to fit.

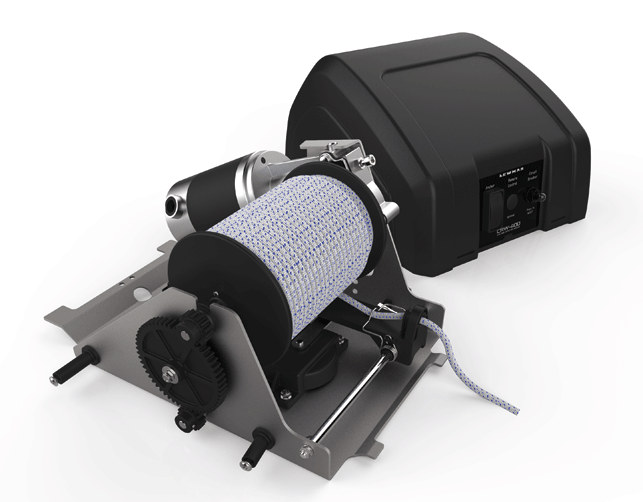

The designers use Keyshot for product renderings. This is a concept for a horizontal windlass product

A product that was born directly from a customer request was a portlight solution for Sunseeker. Lewmar’s design team worked closely with Sunseeker’s designers on the stainless steel round portlight, which is now part of the Lewmar range.

“Sunseeker were buying a particular stainless steel portlight from a competitor in America. However, their procurement team wanted to knock some cost out of their boats and as they were getting fed up with that particular supplier, approached us with the product and the restraints and parameters required, and we made it for them,” comments Smith.

In fact, a customer request has spearheaded an entire new division in the company – that of glass. Boatbuilders are starting to use more glass in their boats as it offers advantages over acrylic including clarity, quality and durability. Lewmar offers an extensive range of portlights and hatches that have been available exclusively with acrylic panels but from December 2014 it will be offering the option of glass too.

“Customers like Beneteau and Sunseeker started asking if they could buy glass off us. So it has been a customer driven decision to go down this route,” says Smith.

The space in the factory is currently been cleared for the £1 million production line that will enable Lewmar to CNC cut, wash, laminate, toughen and digitally frit print the glass. With frit printing, ink is applied to the surface of the glass via inkjet nozzles and is then chemically bonded to the glass as it travels through the furnace during the toughening process.

At a later stage, the plan is to also start designing specific glass products such as patio doors and pop & slide windows.

All under one roof

As everything is designed in-house, most of the products are manufactured and assembled in-house too. Volumes of products range from one-offs to tens of thousands a year. Production processes are constantly reviewed to ensure that products are made in the most efficient way possible.

However, not everything can be done in-house and Lewmar does rely on suppliers. For instance, moulding is outsourced as is the investment casting. “We have a great supplier in the Far East who does all our investment casting for us in stainless steel.

A rope block recently developed for a 85m sailboat. The ‘toggle block’ stands 635mm above deck level, weighs around 75kg and has a 40T safe working load

“Recently we developed a small investment casting for a particular product and sent the CAD file away and within five days we had back a rapid prototype investment casting. It was beautifully finished and all polished just as if it was a production piece. We can do testing with it, verify it and get sign off from the customer all in a very short space of time,” comments Smith.

Of course all products are tested extensively and go through quality control steps during their journey through manufacture. Tests include load testing, salt water spray testing and water testing.

With so many products to design, it’s never a dull day for Smith as Lewmar’s head of design.

“One day we are messing about with gears and bearings and the next we are working on membranes, switch panels and electronics,” says Smith. “It’s a learning curve all the time and great fun.”

lewmar.com

The Lewmar Story

Today Lewmar is one of the most recognised names in recreational boating deck equipment, but back in 1946 when Len Lewery was making Tufnol dinghy fittings, he had no idea that his small business would become a global brand.

In 1950 Lewery joined forces with Leslie Marsh, a local plant hire operator to develop and manufacture his dinghy fittings out of Marsh’s plant-hire shop in Emsworth, not far from its current headquarters. Hence the name Lew + mar.

By 1959 Marsh had sold his share of the company to Henry Shepherd, whose firm made helicopter gearboxes. With the introduction of lightweight aircraft materials technology, the company took strides forward in winch gearbox design.

Then, in 1967, John Burton, a keen yachtsman, acquired Lewmar and embarked on a 20-year career, turning the company into a global manufacturer of modern yacht equipment.

Rapid expansion overseas saw the establishment of eight regional sales offices and in the 1980s Lewmar became a plc and floated on the London Stock Exchange.

Lewmar went through a series of acquisitions and mergers in the 1990s and early 2000s but the biggest change came during the economic downturn in 2008 when Peter Tierney took over as managing director. The company was delisted and the offices around the world closed.

Following this restructuring Lewmar is now a profitable, limited company owned by shareholders. Its distributor network supplies its vast product range to territories all over the world.

Marine equipment – designed and manufactured on-site

Default