At the centre of every new product design by Danish consumer electronics icon Bang & Olufsen is the company’s ‘ideas factory’, a kind of skunk works where the normal rules and constraints that govern most electronics designers’ lives can be ignored.

Bang & Olufsen’s touch screen Serenata mobile phone, developed in collaboration with Samsung

Looming deadlines, design specifications and management pressures are either absent or reduced in favour of allowing Bang & Olufsen designers to explore new ideas, and new ways to translate those ideas into finished products.

According to Bent Christensen, Senior Engineer of Innovation and Prototyping at Bang & Olufsen, “The ‘ideas factory’ is where we first conceive future products and where we turn those ideas into prototypes.

These prototypes could be for a television, a remote control, or a mobile phone. We design the interfaces, the electronics and the mechanicals destined for new products and then test, analyse and see how the prototypes look, feel, work.”

The trouble with paradise

There are particular challenges each designer faces working in the Bang & Olufsen ‘ideas factory’. For Christensen, it is dealing with all the options and eventual changes in each prototype. Each new prototype is a blank canvas: there’s no PCB, no intelligence, no user interface, no external case.

We design the interfaces, the electronics and the mechanicals destined for new products and then test, analyse and see how the prototypes look, feel, work

“We normally start with one idea, and then change to another because there was something we hadn’t thought of. Then we keep making changes until we get it right.

There are so many things that we need to consider when developing our prototypes,” said Christensen, “and having the freedom to change over and over again is very important.”

Christensen deals with a high level of complexity in his designs. As electronics technology evolves, device packages shrink and designs get faster. Design tools need to rise to the challenge, and the designer’s skills need to change continually. This, and the need to manage design complexity, can distract the designer from exploring and creating designs that deliver a unique customer experience.

And an ‘ideas factory’ should not be about the low level slog of managing design processes. It should be about developing innovative designs using inspiration and vision.

Reaching new levels

Anyone familiar with Bang & Olufsen products will know that each product is designed to dictate new fashions in multimedia equipment. This is a classic case of electronics and mechanical design processes having to work in harmony. In an ‘ideas factory’ requiring creative freedom and a rapid turnover of design prototypes, this might be a recipe for design and management disasters.

Christensen deals with unique mechanical casings, and linking these with the electronics used to be a real challenge. The Bang & Olufsen ‘ideas factory’ uses Altium’s unified design solution, Altium Designer, and its real time 3D PCB visualisation and STEP file import capability allows high-accuracy, 3D STEP files to be imported from the MCAD domain into the ECAD space.

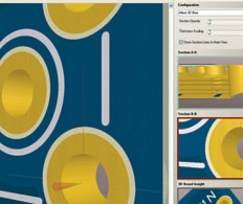

Clearance checking in Altium Designer

The once separate processes come together, allowing the complete product to be modelled and visualised within Altium Designer, in 3D, and in real time. Using this feature, Christensen can perform interactive clearance checks between the mechanical and electronic assemblies to test how a PCB fits into its enclosure.

And if there are packing violations, changes to the board can be easily applied in the 3D PCB editor, then the board assembly sent back to the MCAD space as 3D STEP files. This can be done at any time throughout the entire design process, promoting ECAD-MCAD design cooperation without disrupting the workflow.

This 3D import-export feature is particularly beneficial to Christensen. He can reduce ECAD-MCAD design iterations to a single clearance checking procedure. “It’s a quick way to design. It helps us to make sure that it fits into the design. It’s just a good way to do it.”

Design without constraints

Using Altium Designer, Christensen can also link to external company databases and draw footprints directly onto the schematic. Altium Designer’s unified libraries are of particular benefit here, and allow the ‘ideas factory’ to maintain custom libraries that are assembled project by project. Christensen and his colleagues can explore and develop ideas without being constrained by existing library

data. Independent libraries, easily managed and updated, give the team the exact component models and data they need.

“Integrated libraries make it easy to make your own unique components. You can simply draw the footprint and place it on the schematic as you like it, so that it fits precisely. You can have your own libraries, with your own components, with your own kind of styling. This is important to us. Our products are unique, so our electronics need to be also,” says Christensen.

This whole process, where components need to be changed and redesigned, and designs re-evaluated and trade-offs made, is an easy process using Altium Designer, because its unified architecture and design environment make it easy for designers to take a holistic approach to design. This means that all the design domains – schematic, board and FPGA – share the same, single data model. Changes made to the design, whether it be early or late in the development process, are automatically reflected in each of these domains with a single key stroke.

3D visualisation in Altium Designer

It allows Christensen to approach a new design as a single focused task, rather than a series of interconnected processes. He considers the design as a whole, experimenting and exploring ideas until he finds the best solution. With this approach, changes to materials and designs are not encumbered by the usual re-formatting or revision problems that used to impede development.

“One example is the touch screen for the Serenata mobile.

There were so many changes with this design. We needed to explore new ideas. For example, we needed to consider power consumption and battery power. After several prototypes and trial and error, we finally completed the design and made the touch screen out of glass,” comments Christensen.

The unified design environment and single pool of design data provide the context for smooth schematic-PCB synchronisation and fast, automatic pin and part swapping. Working between what are traditionally separate processes, these actions are unified at the platform level within Altium Designer’s single application design environment. These and other unified design features have allowed the ‘ideas factory’ engineers to get on with the task of exploring and developing ideas. Many of the previously tedious and errorprone processes have been automated.

“Altium Designer lets us create prototypes rapidly and without fuss. For example, prototypes that once took a month to complete are now finished in half that time. Design throughput has doubled. The holistic approach and Altium Designer’s unified architecture make this possible. And with constant updates to the software, rapid prototyping just gets easier. The introduction of unified database libraries means we can place up-to-date, preapproved components straight onto the schematic. And the 3D visualization engine means we can fit our boards into their cases and reduce MCAD ECAD revisions to a single clearance checking procedure.

“It’s features like these that allow us to complete designs quicker and with more confidence.”

www.bang-olufsen.com

www.altium.com

Altium Designer helps unite the worlds of MCAD and ECAD for Bang & Olufsen