In many areas of the developing world, there is extremely limited access to electricity, and many places have never had any type of power infrastructure.

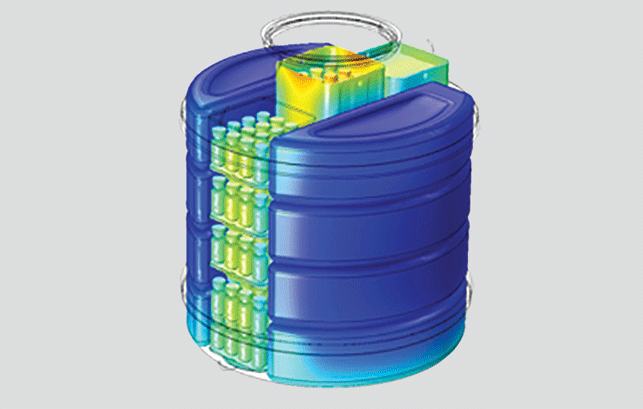

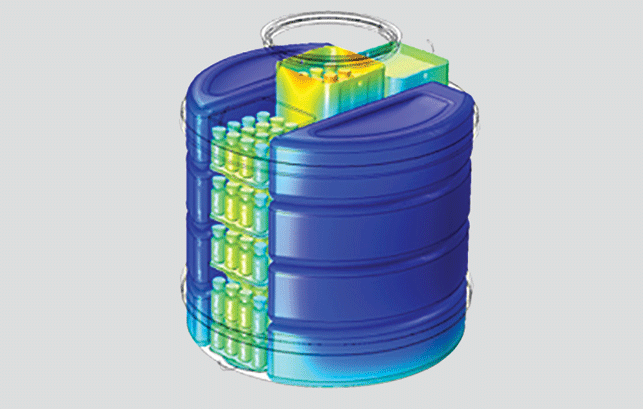

Thermal simulation of the PVSD shortly after loading; the process of melting ice blocks is modelled using the phase change feature in COMSOL Multiphysics

This presents a huge challenge for aid workers and doctors. In the very recent past, vaccines that needed to be stored at cold, relatively constant temperatures could not be taken into the remote areas where they were needed most.

As part of the Global Good program at Intellectual Ventures (IV), a team of innovators invented a thermos-like container called the Passive Vaccine Storage Device (PVSD) that uses high performance insulation to completely change the way vaccines are stored in areas with little or no electricity.

Strict safety requirements

If not kept within the necessary temperature range at all times, vaccines can spoil and become unusable. Global Good’s researchers were tasked with following the parameters dictated by the World Health Organisation. To be delivered safely, the vaccines are required to stay within a narrow window of 0° and 10°C.

The first prototype that the researchers designed was based on a cryogenic dewar, a device that relies on vacuum and multilayer insulation technology to store extremely cold liquids. Dewars that can normally hold liquid nitrogen or liquid oxygen for extended periods of time were only able to hold ice for a few days before it melted.

Global Good’s researchers used experimentation along with thermal and vacuum system modelling with COMSOL Multiphysics in order to identify materials and designs that would allow the PVSD to maintain high vacuum levels at high temperatures. Like a cryogenic dewar, the PVSD relies on multilayer insulation within a vacuum space to minimise heat transfer.

The PVSD uses similar temperature control storage methods to a cryogenic dewar. With a single batch of ice, it can store vaccines for extended periods of time

The high quality vacuum virtually eliminates convective and gas conduction heat transfer, while the multilayer insulation dramatically cuts down on radiative heat transfer. The multilayer insulation, made of reflective, extremely thin sheets of aluminium and a low conductivity spacer, is similar to materials used in spacecraft.

Simulating vaccine storage

Researchers for Intellectual Ventures’ Global Good program used an environmental chamber to recreate conditions similar to the climate in Sub-Saharan Africa in order to rigorously test and understand the performance of their prototypes.

However, building a quality prototype of a vacuum dewar is an involved effort, so to explore different design directions more efficiently before building prototypes, the team turned to COMSOL Multiphysics and its Heat Transfer Module and Molecular Flow Module, among others.

Their challenges included optimising the internal geometry for maximum cold storage time, maintaining higher vacuum capacity, and managing outgassing in the vacuum space. The minimisation of outgassing is critical, as even moderate amounts of residual outgassing within the vacuum space over the life of the PVSD can cause the vacuum to lose its integrity, increasing heat transfer into the device.

The geometry of the device is optimised to maximise vaccine hold time and to be as accessible as possible for health workers in the field. As a first line of defence against the elements, the outside of the device consists of a metal enclosure padded with protective rubber bumpers, while the inner part of the PVSD consists of a smaller shell connected at the very top to the outside with a cantilever neck.

Because of this design, conductive heat transfer can only happen at the connection point. In addition, a composite neck maintains the vacuum space so that there is no gas permeation from ambient air.

According to David Gasperino, one of the engineers deploying COMSOL to support the PVSD design effort, “COMSOL Multiphysics is great for reducing the amount of time spent on complex models.”

He went on to say that they especially appreciated “having everything flow together in a seamless, easy-to-access way, where the multiphysics couplings are spelled out very clearly.” The team found the breadth of modules available helpful for capturing the complex physics they needed to explore with their models.

Improving the design

As a result of the experimental and theoretical work that went into the PVSD, the device is capable of making a significant impact on the vaccine cold chain in the developing world, allowing vaccines to travel into more remote regions and to be stored for longer periods of time without the need for power.

Down the road, Intellectual Ventures will improve their storage device designs to keep vaccines cold for extended periods with even more efficiency. The team will continue working to create groundbreaking tools with the ability to save lives around the world.

//www.youtube.com/embed/gSHEOa9jq0U

Innovative thermal insulation techniques help bring vaccines to the developing world

Default