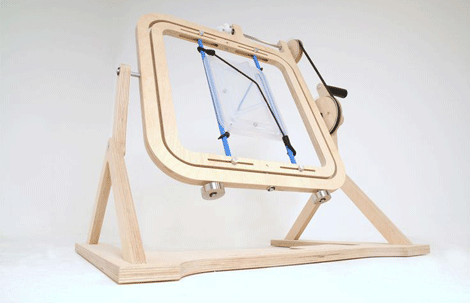

A simple desktop rotomoulder like this is the baby of the bunch

Recently we paid a visit to London-based design consultancy PDD, and although we left having learned about its work on lots of various projects, one thing stuck in our mind – a mini rotational moulding machine.

‘Rotomoulding’ is a way of turning a liquid resin around inside the mould so that it eventually sets as a solid having thinly coated the form of the mould (but you already knew that), spinning and tumbling around, with occasional jerks and pauses to get the most consistent finish.

Despite being in the costly confines of West London, PDD still has space for a well equipped workshop, in which PDD’s principal for design development Mark Hester showed me the mini rotomoulding rig he’d built for moulding plastic bottles.

Made from wooden frames on metal axis, it is driven by an Arduino and churned out the finished goods quite happily. Mark also explained that he’d hooked it up so it could be checked wirelessly over the internet (by his own admission, a bit of a personal IoT challenge, but something he was keen to try out!).

Seeing design consultancies knocking up bits of their own kit in house to solve a problem (spare a thought for the person manually rotating a few hundred bottle moulds should they not have built the rig) is one of the great things about our visits.

Although, having said that, it did set me off looking at the professional machines available.

At the small end of the scale, Studio MyFirst designed this little desktop, hand-cranked model, similar to the one found in PDD’s workshop, which could be happily re-jigged to make it electronically driven.

The product of a final year project from the University of the Creative Arts, this flatpack, low-cost option is sadly sold out, but could be replicated.

//www.youtube.com/embed/Ok4fAqjKMoI?rel=0

Taking it up a gear into production there’s the likes of Orex, a company that produces industrial rotomoulding machines from Poland.

With no need for pressurised manufacture, there’s less cost in producing moulds, while the process can also provide multi-layer forming.

While the process still requires heating (big blue shed) and cooling (spinning it around outside of the big blue shed) it’s a relatively inexpensive means of producing functional things like water, oil and fuel barrels.

Elsewhere, the more industrial processes bring in a level of compression (the pressure helps speed up the cooling of parts and reduces sinks in the parts) and automation, ferrying multiple arms around a carousel of loading, heating, cooling and unloading.

And then it all gets a bit silly – like ‘making a boat’s hull in a big cocktail shaker’ silly.

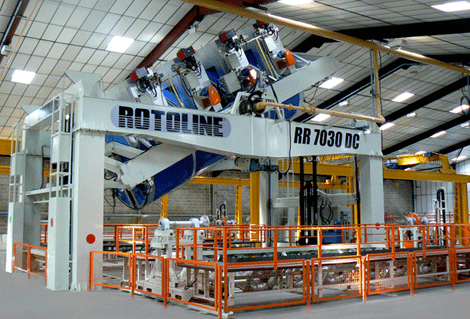

Rotoline produce giant industrial rotational moulding equipment, including the Rock and Roll Oven Shuttle for making boat hulls

Brazilian company Rotoline builds massive rotomoulding machines, including the Rock and Roll Oven Shuttle, with a huge central oven measuring 7 meters long by three meters in diameter capacity making it possible to produce large tanks, boats and whatever other huge hollow products you can dream of.