Al Dean has never been convinced about 3D printing becoming mainstream, but he may be about to change his tune. Here’s how a big pink flying tent, a wireless weather station and a garden shed helped.

The UP personal printer – can sit on your desk, print you parts, and be another tool in your box

3D printing is getting a reputation amongst the mainstream media as something that’s new, something that’s got promise.

The more enthusiastic of the pundits out there are claiming that it represents a brand new industrial revolution – you can see this everywhere from Wired to the venerable Economist. 3D printing is coming and it’s coming to your home soon. Is it? I have my doubts.

Personally, the idea of 3D printing becoming mainstream has never sat well with me. I’ve been working with these systems for nearly two decades and writing about them almost as long.

My opinion has always been that there’s huge potenital for designers and engineers to do interesting things that don’t conform to either traditional design for manufacturing rules or indeed, traditional tooling vs part cost economies of scale.

But did I foresee a day where everyone had one in their house to print new bits for their vacuum cleaner? Not a cat in hell’s chance. And I’ll tell you why.

3D printing isn’t easy. Or rather, the process of designing a part isn’t easy.

Yes, there’s a whole raft of 3D design tools out there, but you can’t just jump in, design a part and build it. Well you can, but unless you’ve got an idea about what you’re doing, you’ll be building crap. That’s always been my opinion but could the loan of a £ 1,500 Up Personal 3D Printer by the kind folks at Cool Components change my mind?

3D printing on the desktop?

I was curious to know. What can you get for the price of a half decent workstation? Surely it’ll be a bit rubbish. Turns out, I was wrong. The box arrived around lunchtime one Wednesday afternoon.

Eagerly tearing into the packaging I got the various bits bolted into place, got the software installed after a download and got the machine running within an hour. And that included a bowl of soup.

The UP is an impressive little beast – about the same form factor as a standard laptop and will sit on your desk quite happily. Once you have the build platform set-up properly and levelled out (this is key), you’re about good to go.

To be honest, I was taken aback by how easy it was. I remember working with an old SLA 250 back in the day and that was a royal pain in the arse; lasers, optics, vats of resin.

With this thing, you feed in the filament (the UP uses an FDM type approach where each layer is ‘drawn’ using a near molten ABS filament), heat up the tip, calibrate it a little bit and you’re ready to rock. All that within an hour.

But what to bulid?

Chess piece with a staircase inside? Nope. A knock off Dsney character from TurboSquid? Nope. I didn’t want knicknacks or test pieces. I wanted something I needed.

Then I remembered my weather station. Erected onto my shed last summer, it had given me months worth of weather prediction and all manner of joy over into the autumn months until a rather windy day took the kids tent aloft and brought it crashing down on the shed, breaking the brackets to smithereens and leaving me with a wet finger and old wives’ tales to judge the weather.

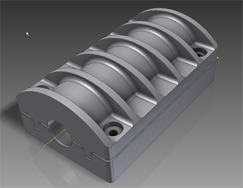

So I found myself loading up Inventor, modelling up a new bracket (which you can see on Thingiverse.com, all documented) setting the printer to build a 1/2 scale part and going out.

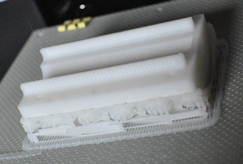

I came back to find a fully built test part. Yes, it took a few minutes to set it free from the support structure, but it was clear this thing worked and worked well.

That evening, I set the full scale build going. With a build envelope big enough to build both components at the same time, I left it running over-night.

Cue a rush down the stairs in the morning to find my new bracket ready and waiting for me.

Twenty minutes later, the weather station was back in action – just in time for Spring.

Final thoughts?

I’m still not convinced that there’s truly a mainsteam market for 3D printers – people just don’t, in the majority of cases, want to get involved in making their own stuff.

But, for those that like to tinker, to experiment and try things out, the fact that these things are now so low cost can only be a good thing. But it’s just another tool for the creative and let’s not yet carried away with anything else. It’s just that: another tool in the box. And we all like new tools.

36 hours with a £1.5k printer can change some opinions of mainstream 3D printing

Default