This month Al Dean discovers that when word gets around that you’ve got a 3D printer, all manner of amusing things start to happen. Is this the 21st century’s “Oh, you’re a dentist?” dinner party conversation?

It would appear that this month has been the watershed for my 3D printing adventures.

I’ve gone from spending a few hours where time permits tinkering with the machine, to finding out how best to set-up a print job and what parameters need to be tweaked to get the best performance for a given task.

It’s a learning process, just like any other manufacturing process. In fact, just like everything in life. I’ve mastered the art of looking at the geometry of a part and considering its required function and adjusting the build orientation.

I’ve learnt where to ease off on support structures and where they’re absolutely critical. At the same time, word about the project has spread. And I’ve had a few conversations, with one, in particular, being worthy of a little further thought.

The 3D photocopier

There was a ring at the door, a handle from a kitchen appliance proff ered, which had clearly been melted. “You know your 3D printer thing? Can you make me a new handle?”

A quick look at it tells me it’s a pretty simple part to make. “Yeah, it’ll take me a little while to model it up. No problems.”

“Model it up?” they ask. I explain that to print one out, a 3D model of it needs to be put together. “Oh. Don’t you just 3D photocopy it?”

I’ll be honest, the phrase 3D photocopier filled me with both a boyish delight (mostly driven by the thought of a new form of office party hi jinx) but it also gave me pause for thought.

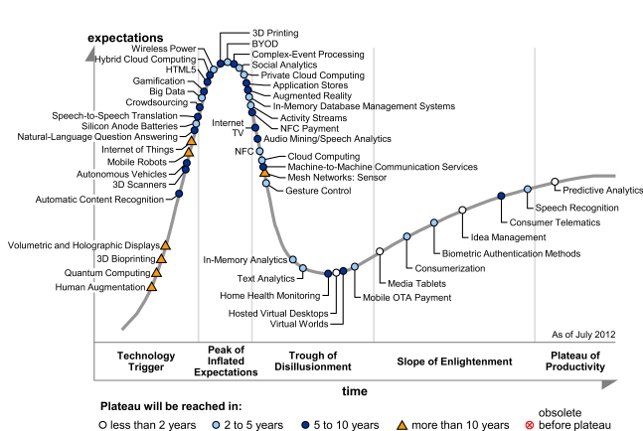

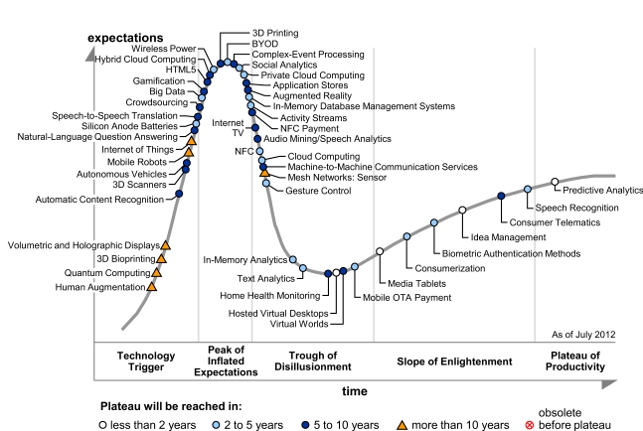

Gartner Research’s 2012 Emerging Technology Hype Cycle shows 3D printing at its zenith (image courtesy of Gartner Research)

As designers and engineers, we’re aware of how these things work. You consider the form and function of the part, you build that in 3D geometry and you send it to print.

For the layman, this isn’t immediately obvious – and why should it be? The vast majority of the world’s populous has no concerns about how a product they use day in and day out is manufactured, let alone the process of design and engineering required to get it to that point.

But most are aware of a photocopier and how it operates. I’ve seen students in the poorest parts of India queuing to use a photocopier on the street. A decade old model, balanced on a few old palettes, wired into the power from a street lamp or a diesel generator.

Whether on the street in Mumbai or in a corporate office in the richer parts of the world, we’re all aware of how they work. You put something in, you get the same thing out (usually).

So consider the 3D photocopier. You’d put the part in. You’d get the same part out. Like for like. Same shape, even if not exactly the same material. But the handle I received is mangled beyond belief.

Anyone that’s done any sort of reverse engineering and laser scanning will know that the process is far from perfect and automated. So the 3D photocopier is a long way off , though it’s a beautifully simple idea.

The trough of disillusion

Again, the question of awareness involved in 3D printing and the precursory activities that take place comes to mind. We’ve seen recently a print bureau offering 3D printing on the high—street and the ground swell of interest gains momentum.

Analyst group, Gartner produces an annual Emerging Technology Hype Cycle chart that shows various technologies and their stage in their evolution.

3D printing is at the apex of the hype cycle. That means that awareness is maxing out and we’re looking at a rapid descent into more realism and fewer over enthusiastic and hopelessly misinformed headlines.

A period that Gartner describes as the ‘Trough of Disillusionment’. We can see it happening already. There’s discussion of people using 3D printers to build home—brew weapons and concerns about environmental impact of the processes.

The good news is that things usually then rebuild upwards from there on in. Expectations are more realistic, productivity increases and people become aware of the benefits and the requirements of how a

technology operates.

It’s at this point that things move from being a new ‘technology’ (often with a 20 year history) to becoming something more usable — a product. Those that have a need or an interest in it will prove it out, improve the technology and it’ll become another process.

Just as printers are a ‘product’: something that’s used without thought, by many.

3D printing – A rapid descent into realism

Default