Chris McGee, managing diector, Lasercut.London

Lasercut.London provides a variety of high-end services that include product design, small production runs as well as prototyping, material consulting, and exciting enterprise projects.

It operates out of a state-of-theart design studio with an adjoining fabrication workshop.

Our materials wall is designed to inspire our clients in meetings with a myriad of samples from around the world

Our Roland LEF12i, which allows us to print white, clear and photo resolution prints onto 3D surfaces and acrylics. It’s great for prototypes

What are your weapons of choice?

We are consistently updating to the latest technology and tools. Our newest addition is the Trotec Speedy 400, a 120-watt laser-cutting machine.

I would also choose the Roland LEF 12i direct surface printer and AutoCAD & Fusion 360, all supported by equipment from Festool, Fein and Mactools.

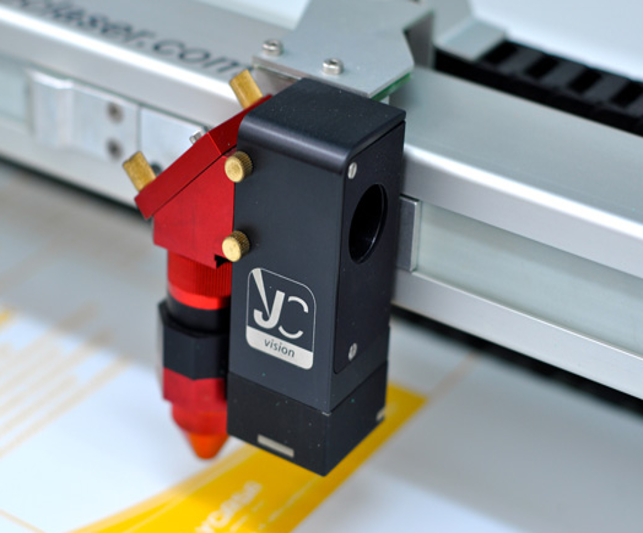

Our brand new Trotec Speedy 400, with 120w cutting power. It has 1,000 dpi engraving ability with the amazing Camera Registration system for perfect cut and print projects

A small selection of our extensive fabrication tools, allowing us to keep most prototype builds 100% in-house

What technology/product couldn’t you live without in your workspace?

All my tools are essential to the quality finish I am known for, but, if I had to choose, I couldn’t live without my laser cutter and AutoCAD.

Our laser-cut sculpture for the RIBA Stirling prize, which I designed entirely in 2D AutoCAD. It consists of three repeating parts in acrylic and polypropylene

With cathedral-like windows, we have designed our new studio around the idea of natural light and clean aesthetics

What is missing from your toolset?

A small format CNC router and a Formlabs 3D printer would complete my collection and deliver the last two production methods that we don’t offer in-house.

Is there anything that would make your design process run smoother?

I wish Fusion 360 had the ability to print directly to my laser software, rather than me having to export it every time as a DXF, then open in AutoCAD. This current process seems counterintuitive to me.

Managing director Chris McGee talks us through the tools he couldn’t work without

Default