Industrial smart glasses from Iristick incorporate sophisticated electronics, while retaining strength and lightness for safety and comfort

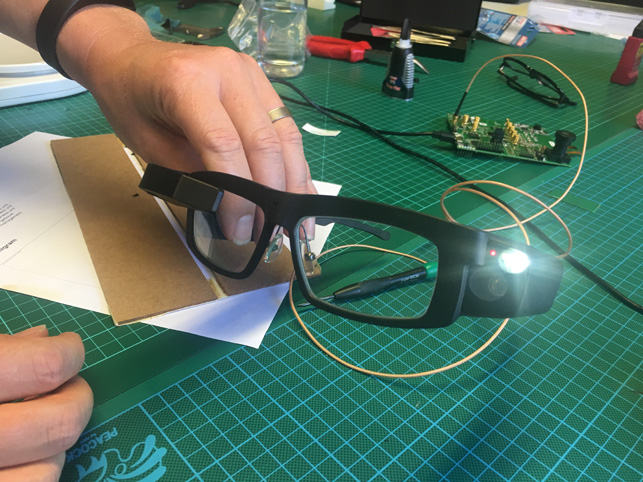

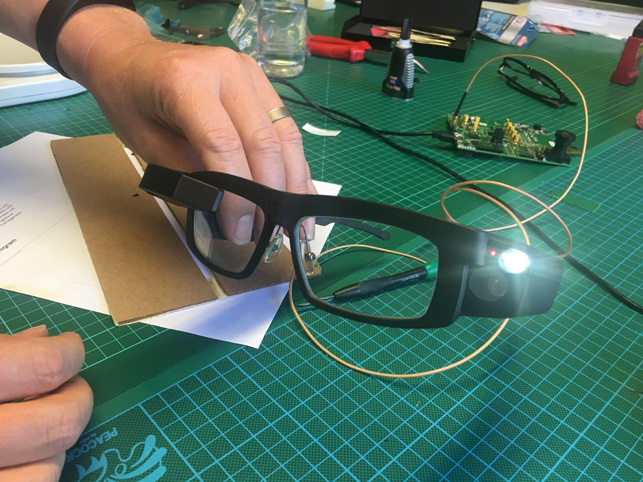

Packed with sophisticated electronics, yet light and comfortable enough to wear all day, Iristick’s smart safety glasses allow operators and inspectors on factory floors to view vital information about work tasks, stream video data in real time to colleagues and call up the technical data they need to get a job done.

Built-in tools such as voice control and barcode scanning help them execute industrial tasks hands-free and the eyewear meets strict industrial safety standards.

Had it not been for the innovative design and manufacturing story behind these glasses, however, wearers might have waited much longer to reap these benefits.

Two years ago, Belgian start-up Iristick began to tackle the challenges of industrial eyewear, and the problem of encompassing significant and complex electronics into their frames without compromising fit and comfort.

As a start-up, the company also had to balance these requirements with the need to follow a cost-effective design process, in order to minimise business risk.

“Essentially, we formalised the concept in a very pragmatic way, by listing out all the reasons why this had never been done before and deciding we would create a product that would tackle all these elements,” says Iristick CEO Riemer Grootjans from the company’s headquarters in Antwerp.

Nobody had previously been successful in achieving smart safety glasses because of the trade-offs required: creating a product that could meet the strength requirements of safety glasses, at an acceptable weight, while simultaneously adding more mass in the form of delicate electronics required for sophisticated function.

Space, or rather the lack of it, was the key design hurdle.

Speakers and cameras are vital to many use cases in industrial environments

Iristick – the eyes have it

With smart glasses products that have gone before, technology always dictated design – to the extent that they might be described as ‘face-worn technology’.

Adding the safety element magnified the problems, so Iristick brought in Belgian product design specialist Achilles Design, along with eyewear designer Philip Hoet, to ensure that every idea was not only a move closer to technical clarity, but also aesthetic perfection.

“What we wanted was a pair of glasses that offered the right balance, the right weight, the right nose rest. Everything you would associate with comfortable eyewear,” says Grootjans. “Rather than being a linear process, it was actually more like making sure three paths – weight, technical capability, size – were all moving at the same pace towards a central goal.”

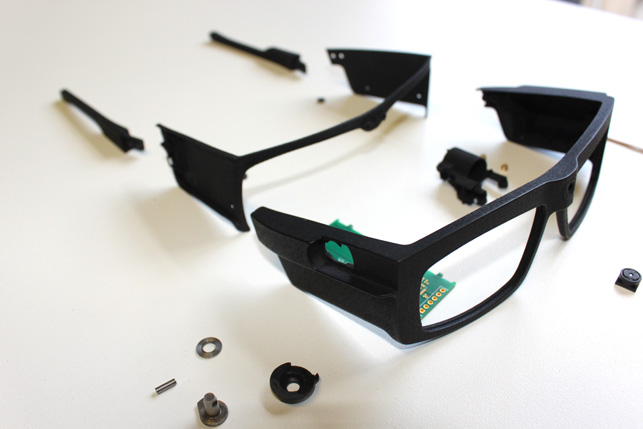

From the first design meeting, this process took nearly 12 months, working through lots of sketches and taking the design into 3D using SolidWorks.

The issue of cramming everything into the space was tackled by designing exactly the right voids for the electronics and acoustic spaces in the frames needed to accommodate the internal speakers.

Using its in-house Ultimaker 3D printers to prototype concepts from day one, Achilles Design was able to iterate on different ideas quickly.

“One of our slogans here is ‘Prototype early and prototype often’,” explains Philip Madden, senior industrial designer at Achilles Design. “We certainly followed that in this case.”

“With this project, the user literally comes face-to-face with technology, so testing our ideas in a physical form was crucial for the ergonomics of the safety glasses.”

Finer details

Concepts were refined further using Achilles’ Stratasys Objet24 3D printer, which allowed finer details and wall thicknesses to be tested.

As the project began to move towards production, the team choose to continue using 3D printing and approached additive manufacturing solutions provider Materialise.

“Requirements dictated solutions and, with this in mind, we worked closely with Materialise to select the best process and materials to fit our brief,” explains Madden.

“Laser Sintering gave us almost unlimited design freedom, while using PA12 was a clear choice because of its inherent properties – chemical, thermal and impact resistance, while also being durable and very light.”

Materialise also brought its previous experience of working with eyewear manufacturers to the design of the smart glasses.

Iristick was determined to have the only smart glasses in the world adjustable to the wearer’s ears. However, the internal electronics meant that heating and bending the glasses’ arms – the normal adjustment method – was impossible.

Instead, Materialise added its own patented spiral-like structure to the 3D-printed arm, a clever solution that allows cold bending for the perfect fit.

“To complement this,”says Grootjans, “we developed a clever assembly sequence that employs a flexible heatshrink sleeve to package the electronics. We solved the problem together.” “We must have produced hundreds of prototypes over the entire process,” adds Madden.

“That’s the beauty of 3D printing; design iterations are so quick. The process also involved a lot of research, including consultations with optometrists and safety experts, in order to ensure we were covering every angle.”

Once assembled, the current version of the Iristick C1 glasses weighs a mere 62g

The need for speed

The speed at which features could be tweaked and tested meant that Iristick was able to slash six months off its anticipated design cycle.

Most of the housing components are cleverly designed to take advantage of 3D-printed production, meaning the current version of the C1 glasses weighs a mere 62g.

Each model comes with a 9-axis motion sensor and a 3-axis adjustable head-up display in the right lens.

As well as voice commands, the glasses offer touchpad gesture control, zoom functionality (the Z1’s zoom lens can read barcodes from two metres away) and support ‘you-seewhat-I-see’ applications for remote assistance.

“For instance: an expert assisting from a control room can zoom in to inspect a small detail as if he was standing right in front of it,” explains Grootjans.

Materialise worked with Iristick and Achilles to optimise the design for 3D printed production, with market-ready models produced in small batches.

Iristick’s C1 and Z1 frames are already out in the field being put to the test and providing feedback that will allow for further design tweaks and iterations.

“3D printing has helped us reach this point, but it also gives us flexibility moving forward,” says Grootjans, describing how the company can test a design with clients and make bespoke changes if needed, even down to custom colours or surface textures.

“We just change the design slightly and print as many as we need, without having to disrupt supply to other clients,” he says.

“We started off thinking 3D printing was simply going to take us from A to B. Thanks to our partnership with Materialise and Achilles, we can go a lot further than that.”

Industrial smart glasses come into focus at Iristick

Default