The new Scania R450 truck

Having a pleasant driving experience is a key determinant when purchasing or driving a vehicle. For companies buying trucks and for truck drivers, it is also a matter of health and productivity. Most drivers spend more than eight hours a day in the truck cabin.

High noise levels or unpleasant sounds are known to cause excessive fatigue and health problems. As such, it is crucial that truck manufacturers design new products and shape the cabin noise to ensure that drivers are guaranteed the most positive working environment possible considering the amount of time they spend driving.

With a wide range of premium trucks, Scania, a global truck manufacturer, aims to design trucks with outstanding comfort and performance. Its Complete Vehicle Acoustic Department is focused on getting its vehicles up to speed with today’s drivers’ expectations by addressing the level and quality of cabin noise.

The development for more optimised cabins is supported by extensive testing and the introduction of new methods based on vibro-acoustic simulations. For this endeavour, Scania’s development team use Actran, a product of FFT, an MSC Software Company, to improve its designs and shorten design cycles.

Driver environment inside one of Scania’s trucks

Scania – Challenges in the design process

With more and more stringent constraints on the design of new trucks coming both from legislative regulations and customers, new methods have to be developed to ensure a more robust and efficient design process.

When it comes to cabin noise, according to Per-Olof Berglund, senior engineer at Scania Complete Vehicle Acoustic department, most of the activities at the company are measurements and tests and, as such, the aim is to use more simulations.

In order to replicate the sounds in the physical environment, the Scania team needed to understand what the different noise sources were and identify how they directly affected cabin noise.

“For two years, a number of cross-functional simulation projects between several departments were started to get the complete picture of the noise in the cabin,” explains Berglund “We want to be able to design sound by adjusting contributions from different sources.”

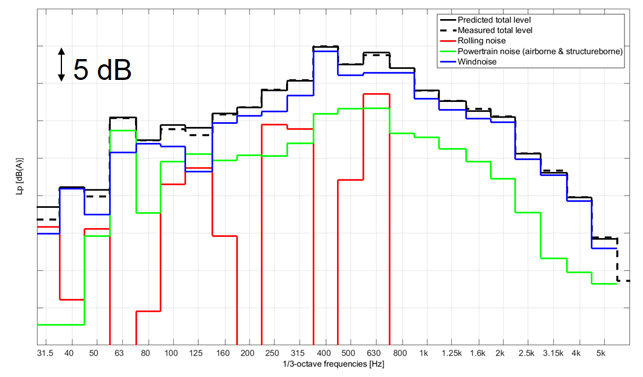

The Complete Vehicle Acoustic department first had to narrow down the main contributors of cabin noise in the vehicle. They found that the main sources were wind noise, powertrain noise and rolling noise. They then identified the typical frequency content for each of these noise sources.

With this valuable information, the natural next step for Berglund and his team was to find a software solution that was able to predict all of these major noise sources, and the response of the cabin structure to these excitations.

“I found that the integration between Nastran and Actran was very good. It was the perfect tool to choose for the simulation, especially for representing the acoustic load and for trim modelling. It’s a perfect companion to Nastran,” claims Berglund.

Scania’s Listening Studio for subjective evaluations

Scania – Simulation solution

Berglund has been spearheading the Complete Vehicle Acoustic department efforts in developing new methods to address cabin noise at Scania. He started his work using MSC Nastran for structural dynamics and acoustics, specifically for powertrain noise and structure-borne noise in the cabin. As the need for more complex acoustic calculations emerged, he then chose to use Actran for its wide range of capabilities, such as accurately solving the response of the cabin including trim components.

“I started with airborne engine noise,” says Berglund. “From the engine department I have the node velocities computed by MSC Nastran. I use Actran to get the acoustic load on the outer surface of the cabin and finally, the noise inside the cabin.”

Berglund has also been working with the aerodynamics department to compute the wind noise at the driver’s position based on CFD calculation results that his colleagues provided. “The CFD results are mapped on the outer surface of the cabin and then, the results are computed inside the cabin using a Modal Frequency Response,“ he adds.

Berglund is currently working on creating models for exhaust noise and powertrain structure-borne noise. Once these models are completed, he will be able to simulate all of the main contributions of cabin noise.

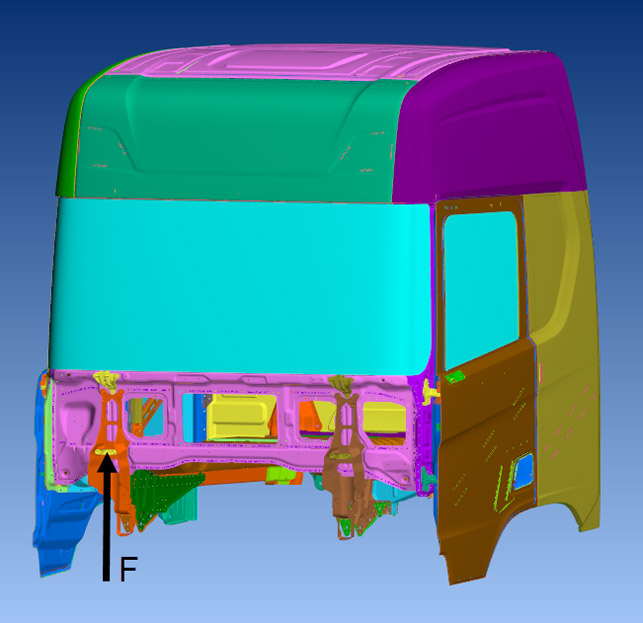

Simulation of structure-borne sound in a Scania truck with the use of Actran

Listening studio

Scania aims to increasingly utilise Actran’s simulations results to compare different designs and define the design directions early in the product development cycle, without the need for physical testing. To support this decision making process, a listening studio was built at Scania.

The studio is similar to that of a professional mixing studio. It encompasses a 7.1 surround system for sound and is designed to produce exactly the same listening experience for anyone who is seated in the centre of the room. During subjective evaluation sessions, Berglund conveyed to his colleagues the findings based on his simulations.

Sources ranking for Cabin Noise at 90km/h

He combined test and simulation data to replicate the environment of driving an actual truck. This process helps managers to make important decisions, which will affect the design of the cabin.

“It is a very different response from management when you can lay a sound and they can have this subjective experience,” says Berglund.

“It’s not really possible to understand from a graph what you will hear in the truck.”

With the use of Actran in this new simulation process and the subjective evaluations allowed by the listening studio, Scania now has the tools needed to improve its customer driving experience even further, as well as having a more efficient design process.