Rurok Industries is taking on some of the biggest names in mountain biking through fresh thinking, engineering and passion – not to mention a hefty dose of design innovation, including generative optimisation

Imagine you’re a degreed electronics engineer, working in the semiconductor industry in the Philippines, while spending your weekends tearing up the trails on mountain bikes with your friends.

Now imagine becoming so obsessed with mountain bikes that you end up switching your postgraduate master’s degree subject to mechanical engineering and going on to build a business with your friends that takes on some of the biggest names in the cycling world at their own game.

This is exactly what PJ Tolentino and his team at Philippines-based Rurok Industries have achieved, thanks to a combination of fresh thinking, innovative engineering and passion by the metric ton, not to mention an openness to new digital design approaches.

Rurok Industries was founded on two core principles: a true passion for mountain biking and engineering innovation. Its current products demonstrate this in equal measure.

The Cordillera, Rurok’s first product, named for the Spanish word for mountain range, is a full-suspension bike with an ultra-efficient patented suspension system that owes much to topology optimisation.

Rurok’s latest model, meanwhile, is the Kanlaon, named after an active volcano in the Philippines.

This is an all-mountain, hardtail bike, with a patent-pending variable geometry mechanism, allowing riders to choose not only their wheelbase, but also their frame geometry, with simple adjustment of two components.

As the Rurok team put it, Kanlaon riders can choose whether they want “to slay or to play” on the trails.

Rurock – a start-up with passion

Engineers and designers have a natural affinity with bicycles, because most people have ridden one at some point, even if not recently, and it’s a cool mechanical object.

Additionally, everyone can understand how they work – there’s no mystery or specialist knowledge required. That said, it’s one thing to have passion for a sport or activity, but it’s another to turn that passion into a business.

According to Tolentino, it happened gradually “From the start, we tried to minimise risk. We started with wanting a better bicycle for ourselves. It was just us thinking, ‘This might be a good bike for us to ride on,’” he says.

“When we showed our first product to everyone, we noticed people were getting interested in getting one for themselves. That’s when we decided to turn this into something proper. That’s how it turned from an engineering fancy into a business.”

In order to fund the fledgeling business, Tolentino and his co-founders sold their own bike collections and got to work.

Rurok’s first product, the Cordillera, was designed to withstand the world of racing. Trails are very steep, very rocky and riders entrust their lives to their bikes.

According to Tolentino, there is only one goal: “To go fast.” In order to do that, downhill mountain bikes typically have a suspension system, a shock absorber that helps riders cope with bumps and jumps.

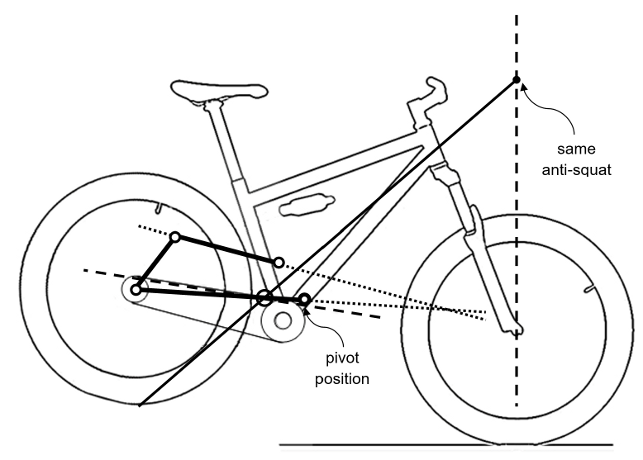

However, this comes with a trade-off. When you pedal, the suspension system is activated, and some of that pedalling energy is lost through the system. For the Cordillera, Rurok designed a new system, for which it has applied for a patent, that it describes as, “Always efficient, all of the time.”

The metric they use is anti-squat, referring to how much a suspension mechanism itself resists suspension compression under loading, in the case of bicycles, from rider pedalling. Rurok has managed to keep this within 5% of ideal even during suspension movement.

According to Tolentino, the big challenge the company had was taking the idealised layout of the suspension system, the kinematic principles, and turning that into a CAD model that could be manufactured. Handily, as part of the start-up process, Tolentino’s team joined Siemens’ Solid Edge Start-up Programme, which offers Solid Edge to qualifying new ventures, along with support where needed.

Rurok – easy transformations

But what about the development of the Kanlaon? After all, while the Cordillera’s suspension takes a new approach, the problem it solves is a longstanding one. With the Kanlaon, by contrast, the team’s solution is quite abstracted from the problem it looks to solve.

According to Tolentino, the most avid fans of mountain biking frequently struggle to decide their preferred configuration of mountain bike – whether they want long or short wheel base, for example, or whether they want a low or higher riding position. As a result, most passionate riders will have multiple bikes, and choose between them based on the type of riding they want to do and their own preferences on the day.

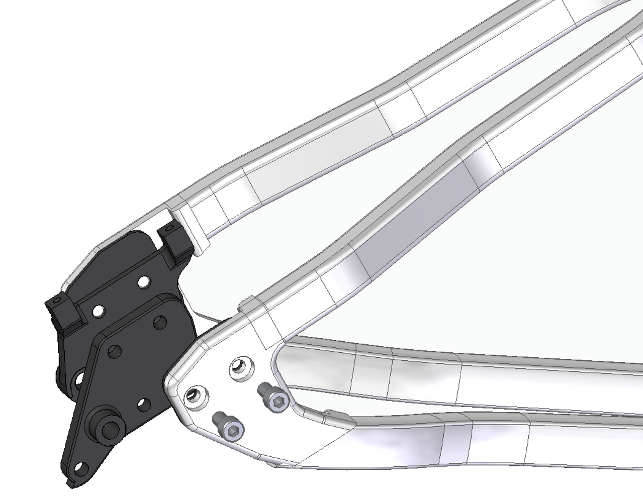

What the Rurok team has done is to build an innovative arrangement at the rear of the frame that allows a rider to vary riding characteristics with a single bike frame. With the simple adjustment of two components (a procedure that involves loosening and tightening four bolts), riders can have their cake and eat it. The dropouts (which connect the rear wheel to the frame) can be adjusted by 20mm, making a huge difference to the riding experience and the character of the bike.

As Tolentino explains: “It looks very simple, but it’s very complicated to design. Especially as we were doing it from scratch and we needed to incorporate derailleur, gear sets and brakes. We went through 20 different design iterations until we achieved the final design and we couldn’t have done this without our digital design process.”

Third time even luckier?

With both the Cordillera and the Kanlaon available on the market and being ridden hard by enthusiastic owners, Rurok has now turned its attention to developing a third product.

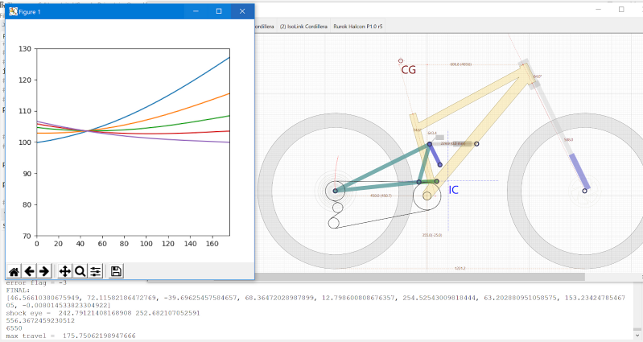

Codenamed the Halcon (named after Mount Halcon in the Philippines), this is an all-out, full-suspension frameset for riders who want to push their limits. With the goal of always looking to improve on its bikes with each new model, Rurok took lessons and technology mastered in the development of its previous products and applied them to this brand-new project. Rurok also took on a parametric optimisation process, in order to better explore the design space and find new room for innovation.

“This time, we changed our suspension design philosophy. It’s very difficult to reduce the anti-squat performance metric, because it’s intricately linked to a lot of other factors. There’s a lot of geometry and parameters involved,” Tolentino explains.

For the Halcon, the team wanted to factor in the effect of gear sizing on suspension performance, something that previous methods didn’t allow. To step up its optimisation game, the team developed their own code, which used an algorithm called Particle Swarm Optimisation. Says Tolentino: “We searched the design space for the best layout that produced the best performance metrics and we’re very happy with how the Halcon turned out.”

As the team went through the process of turning the optimised suspension system into a manufacturable product, it also encountered other issues. To solve these, it turned to Solid Edge’s generative optimisation tools.

For example, it discovered that a key component, the shock absorber, was causing interference with the key linkages that gave its suspension systems their unique characteristics. “What we did was to subtract the shock absorber body from the linkage and then applied generative optimisation to the part,” says Tolentino. “Then we took that design and made it manufacturable. Every gram counts in cycling and, of course, we wanted it stiffer and, of course, not to break. The part we designed was 20% lighter, but retained the stiffness we needed to achieve our performance metrics.”

Rurok – riding into the future

So how is the start-up doing today? Tolentino feels that its testing procedure provides good evidence of Rurok’s positive direction of travel. “Virtual testing is one thing, but road testing is another. To help with this, we have our in-house factory racing team, whose job is to ride and destroy all of the prototype bikes – just to make sure that they are ready for manufacturing. We didn’t tell them to join in and win races, but they’ve won so much I’ve lost count over the last few years. We’re currently the number one ranked team for the racing series in 2019 in the Philippines.”

He also believes that the mountain biking industry needs to move forwards. “We only make bikes because we think we can make them better and that’s why we do what we do,” he says. “We don’t compete on price, that’s not our specialty. Other companies have economy of scale, so they compete on price. We compete with innovation and I think we’re a testament that a small start-up company can be competitive by being innovative. We’ll keep innovating.”

What’s really interesting is how a small team is using a technology such as generative optimisation, alongside other techniques, to help it punch way above its weight and compete globally in a pretty cut-throat business dominated by much larger rivals.