With its global presence, L’Oréal is one of the biggest names in cosmetics and oversees some of the most recognisable fragrance lines from the world of fashion. Stephen Holmes learns how the business of beauty is moving faster than ever, and how innovative use of additive manufacturing is helping packaging to reflect the latest trends

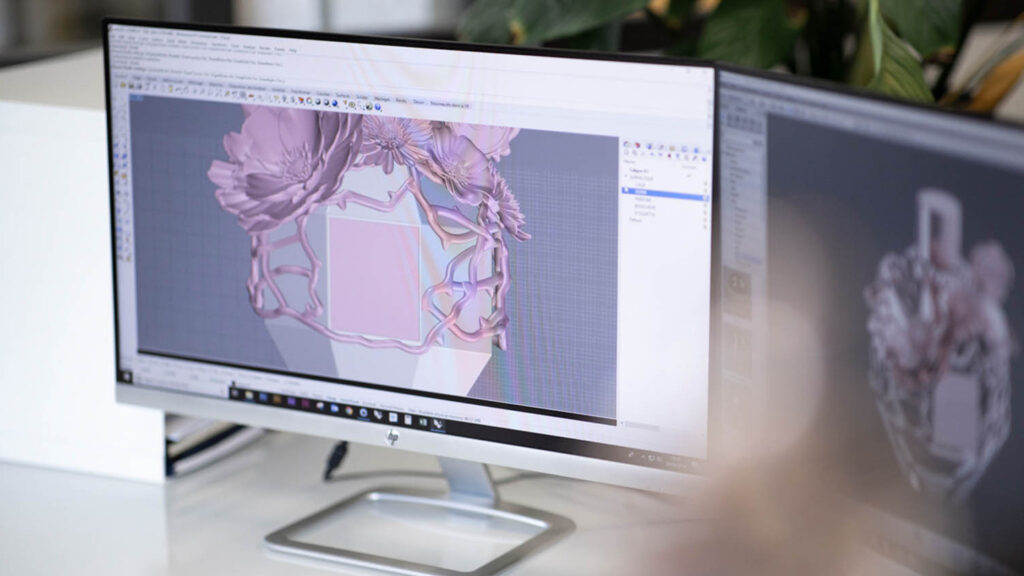

The limited-edition Haute Couture bottle for Viktor&Rolf’s Flowerbomb perfume is encased in a delicate rose gold cage of brambles and the flowers that make up the scent. Designed to celebrate the perfume’s 15th anniversary, it’s also a way for L’Oréal to showcase its recent explorations of additive manufacturing.

This glitzy packaging is an excellent example of the kind of creativity and high-end finish expected of brands within L’Oreal’s portfolio. From luxury labels like Lancôme, Yves Saint Laurent and Giorgio Armani, to household names like Maybelline New York and Garnier, the desire for new products in ever more eye-catching packaging puts even greater demands on design processes.

Since 2018, the global beauty and cosmetics giant has had a dedicated team looking to test and accelerate the use of 3D printing in-house, and the pace has been relentless ever since.

Today, all of L’Oréal’s design centres feature 3D printers, the majority of them boasting a full 3D lab onsite. Over half of its 40 factories are equipped with additive technologies. As a result, the company produces around 15,000 3D-printed parts each year.

Matthew Forrester, head of materials transformation & recycling science at L’Oréal, explains that the company has been using external 3D printing services to aid product development for over 15 years. The more recent decision to bring 3D printing in-house, he says, was driven by increasing need to get products to market faster.

In the past, marketing teams would turn to L’Oréal’s design engineers with an idea for a bottle, who would then build prototypes, sometimes taking up to a week to produce and be shipped from a bureau or model shop.

Today, each onsite 3D lab keeps the technology close to the designers and engineers, “because that’s where we’re gaining time,” says Forrester. “Instead of flipping back and forward by the post, it’s now quickly in their hands.”

Initially, Forrester’s Paris 3D lab set itself a deadline to have a model ready within 24 hours of the design engineer putting the 3D CAD file on the system.

“This year, we’ve moved to 12-hour availability. The idea for next year is that we’ll move it to six hours. We’ve dropped it in half every time,” he says.

Rapid advances

Cutting delivery times in half year-on-year is a huge task, but Forrester points to the rate at which 3D printing technology is rapidly advancing. “The technology is getting faster and faster,” he says, “but we don’t necessarily see it, because every time it gets faster, people prefer to double the quality of the part and keep the same print time.”

The 3D printers that he and his team first experimented with four years ago were capable of printing parts within six hours, he says, but the parts looked horrible. Now, he says, parts produced in that same timescale “look amazing”.

L’Oreal’s Paris 3D Lab has acquired a wide range of additive technologies to assess and test. A lot of work is done with desktop FDM technology, as well as some Formlabs Form 3 resin 3D printers. A Carbon M2 printer, meanwhile, provides the team with fast turnarounds and a wider choice of end-use materials.

Forrester admits that the 3D labs at L’Oréal were slow to exploit the speed advantages of additive because of a traditional prototyping mindset, where a mock-up had to be absolutely perfect, looking identical to a real product. He explains that they offered the designers a new option: they could quickly 3D print them a model, in order to help them make a fast decision about the concept direction, or have three or four different options in front of them, in order to iterate on a design.

At the end of it, if the designers still needed a perfect concept model, they could go through the traditional manufacturers, who would machine, hand polish and paint it to create something lifelike.

“But what we’re interested in, really, is the acceleration and the speed. I think that maybe compared to [other industries], we do have a certain threshold where [designers] won’t accept below a certain quality.”

Another area where L’Oreal is making rapid advancement is to be found in more functional prototypes; 3D printing packaging that is either made of the material that will be used in end production, or that will behave in the same way. This way, L’Oréal’s engineers can make a better decision on the wall thickness of a bottle, or how a product behaves when used.

“If we can get new materials that behave like or are really made of the same product that we’ll put onto the market, that’ll be a huge leap for us, because it means that we can start making decisions without having pilot tooling,” says Forrester. “We’re doing a lot of work on that at the moment to accelerate that.”

L’Oréal – Beauty in a bottle

The idea for Viktor&Rolf was to create an ultra-luxurious, limited edition version of its Flowerbomb perfume, a design that needed to look like “a very precious object”, says Anne Guillou, who was responsible for the project.

“There was a very strong need from the brand to continue to be extremely luxurious, at the same time with the wish to have personalised options for consumers – so how to be able to be very luxurious in very small quantities?”

3D printing was ‘the trigger’ to make the design happen, although because nobody had done something like this before, it took a huge level of research and planning, involving a mix of marketing and technical personnel inside L’Oreal and its trusted external manufacturing partners.

Initial mock-ups lacked the ‘wow factor’ and waft of luxury that was desired, so choosing the right additive technology was critical. The team was tasked with comparing potential 3D printing technologies to get the right surface finish, but also needed to make decisions on how to make it affordable and develop it from a business point of view.

“Carbon’s resin was certainly the best [technology] at the time, and probably is still the best for this type of geometry that we wanted, where we’ve got flowers and movement in a lot of different directions,” says Forrester, comparing the approach to the powder bed fusion and SLA technologies available at the time. He adds that a key factor was that the resin technology also lent itself to having the sumptuous metallic finish applied for the required, jewel-like finish.

With the assistance of French 3D printing experts ERPRO, the Victor&Rolf design was developed for production 3D printing on Carbon’s system, before parts were post-processed, with the final assembly attaching different flowers to each cage, before the design was electroplated and given a final polishing.

“That’s a real revolution for us – to react quickly to consumer needs or to limited editions, or to celebrate something like a catwalk show or something [brands] want to do a limited edition based on. It means that we are now able to reply within a couple of weeks and get initial products out onto the market.”

Additive values

Presently, L’Oréal’s 3D lab teams are looking into how they can bring added value to the consumer using 3D printing in end-use products, and whether consumers are willing to pay for that?

“That’s what we’re trying to move into – added value – for better ergonomics, mass customisation, mass personalisation, maybe new materials that are more respectful for the environment than traditional manufacturing. And local manufacturing is something which I’m very passionate about. But I think supply chains in Europe are not set up in that way at the moment, but it’s something which is slowly, slowly evolving,” says Forrester.

Away from luxury limited editions, the cost of production using 3D printing is still too high for massmarket production, something linked to the necessary post-processing of additive parts.

“We can print parts very cheaply, but the actual price to put them onto the market is not as low as it could be,” says Forrester.

“There are very few fully automatic systems that exist. You always have a print, then you have a removal, and then you have a post-processing step, or two, or three. Then we have a finished raw part. And then we need to apply some sort of finish, whether it’s smoothing, painting, metal plating. Every time we add one of these steps at the moment, within the additive space, it’s a guy or girl who’s taking the parts off the plate and putting them somewhere manually.”

He compares this to development injection moulding over the last 50 years, and its fluid, fully automated factory lines. “No one’s touched it, and the part costs 10 cents, which just isn’t possible today in additive.”

Forrester remains positive that additive manufacturing will one day reach that stage of automation, and believes that is when it will truly begin to shine in mass-market use cases, as every part can be unique.

Until then, L’Oréal has already found what it calls its sweet spot for the technology: using it to set up factory lines.

“All of these parts that are going to build a bottle will take time and money and resources to make,” says Forrester. “We’re switching pretty aggressively towards the additive space for our plants, because we can change things over so quickly and we can react to market needs.”

He gives the example of factory lines producing lipstick as Covid-19 hit. Many customers swapped lipstick for facemasks, and demand for hand sanitizer went through the roof. By using 3D-printed parts, L’Oréal was able to quickly repurpose factory lines, achieving around 50% to 80% cost and agility savings.

This ability to change a factory line over at lightning speed plays into changing consumer demands, and how buyers find and use existing products.

“We have this thing at the moment, which is cool; we call it ‘the TikTok effect’,” Forrester explains. Someone on the social media site TikTok might repurpose a mascara – using it on a beard instead of their eyes, for example. “Something that we’ve never imagined,” laughs Forrester, “and then everyone will run to the shops and buy this mascara that’s been running on tiny quantities for the last 10 years.”

When demand explodes like that, he adds, L’Oréal has to react. “And that’s where additive is really becoming a gamechanger, because we can now change our production lines that quickly.”

‘Quick wins’ are the key to building this speed, and through educating its workforce through its 3D labs, L’Oréal is helping change mindsets about materials, with huge cost and time savings.

Factory line parts that were traditionally machined out of metal, not for particular design or load constraints, but because aluminium and steel were easily available, are now being 3D printed from polymers.

Forrester says: “Everyone’s very surprised by the fact that we equipped a make-up line the other day with FDM prints! We printed 0.3-layer resolution. Really quick wins that we did in a day, we sent all the parts through to the line and they’re still on there, running at 200 parts per minute, producing what used to be done with stainless steel.”

The factory line might be a long way from the luxury of L’Oréal’s catwalk clientele but, in both, additive manufacturing has found a growing role to play.