The type of commercial kitchen solutions that Shine delivers

The kitchen is the beating heart of any catering facility, whether it’s for feeding high level execs, or a military mess hall for 300, the space has to have functionality ingrained in its design.

Shine, a Newport-based kitchen solutions provider, has been building such commercial kitchens for over 40 years. In the last decade it has undertaken over £100M of work, with a vast customer base spanning small cafes and schools, to large Ministry of Defence contracts.

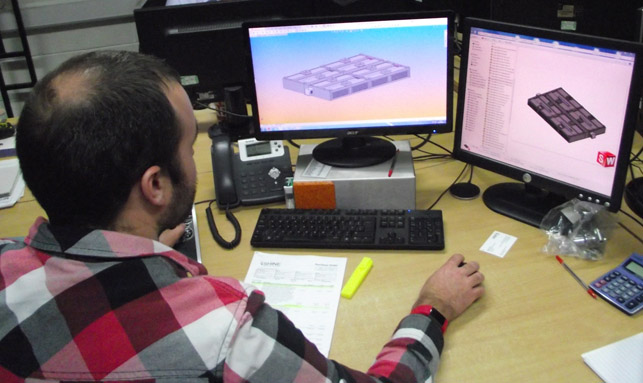

Its solutions are all delivered in-house at its Welsh headquarters, passing all the way through its design team, through to manufacturing and installation.

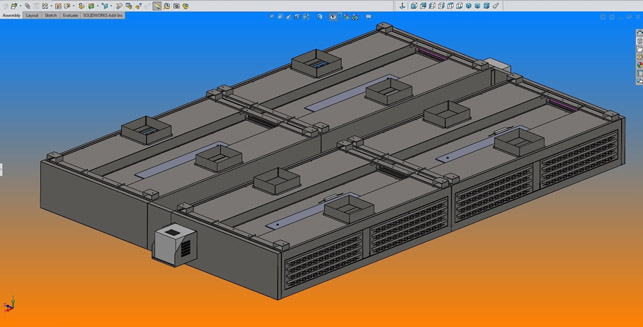

With each job being completely bespoke, Shine manufactures thousands of different components a year, each requiring its own CNC code produced in Radan. With a full servery counter alone able to contain 200 different components, the level of detail has to be sub-millimetre.

“After we’ve won a contract, we’ll design the individual components for the kitchen, such as the extraction systems, tabling and servery counters, in SolidWorks,” explains Shine senior design engineer Neil Thorne.

“Once the client approves the design, and site dimensions are taken, we then provide the factory floor with manufacturing drawings.”

The components are nested, laser cut, folded, welded and assembled before the finished product is then inspected before being delivered to site for installation.

Radan has become integral to Shine’s process. It cuts down the amount of time the engineers spend nesting, especially with the ‘F-Stop’ macro

About face

However, taking its designs to such fine levels of detail, Shine wanted to digitise an aesthetic factor that was causing a problem through design constraints and human error: matching up material grain direction.

“For the aesthetics of our finished installations, we’re governed by grain direction on the sheets. We can’t have neighbouring cabinets with the grain going in different directions…the grain all has to go the same way!” says fastidious Shine design engineer Steffan Owen.

“This was a problem for us because when the project was going into Radan, the software was nesting in the best orientation for sheet utilisation, and sometimes we didn’t have the correct top face, and the grain was in the wrong direction. We needed to overcome this without having to nest everything manually.”

The challenge was taken on by Radan’s team of software developers, creating a macro specifically for Shine to solve the issue.

The high volume of parts in a project coupled with the high-quality materials used, required a highly automated, and at the same time, very reliable process.

“With input from the engineers at Shine, we put together a specification which allowed us to put a process known as the ‘F-Stop’ in place, that allows Shine to produce the kitchens with a minimal risk of costly errors,” says Radan brand manager Olaf Körner.

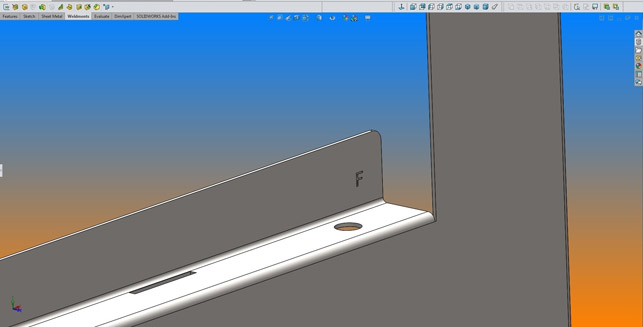

At the design stage in SolidWorks, a 5mm letter ‘F’ is put on the top face of the panel, which indicates the correct grain direction, the Radan macro then determines from the F-Stop which is the top surface and which way the grain has to go while orientating the flat pattern.

Radan then nests with the correct top face and the grain going in the right direction.

Outside of Radraft, Radprofile and Radnest to cut every sheet metal product with a Bystronic Bysprint 3015 3-kW laser, the new macro also helps stops human errors on the factory floor.

Previously parts could be nested either in the wrong orientation or upside down, and even folded the wrong way in the press brake, and had to be scrapped.

Due to the success of the F-stop macro developed for Shine, Radan is now working to include this feature in a future general release of the software, to benefit all its customers.

This new F-Stop macro allows the engineers to put a 5mm letter ‘F’ on the top face of a panel, which indicates the correct grain direction

Radan – Saving scrap

Although the volume of scrappage produced has been largely reduced, Radan also allows these leftovers to be optimised for reuse.

Owen explains that the use of the ‘remnants’ feature means that Shine’s scrap no longer goes directly to waste.

“Every offcut is put back in the system; and the first thing Radan does is to look at a remnant first rather than use a new sheet. That way we’re saving on material as well.”

Using the projects and labelling functions has also increased efficiencies, both in design and in manufacture.

“By using projects we know where everything is,” continues Owen. “The factory floor rely on it a lot…along with the labelling system.

“All parts are labelled automatically which is really crucial for identifying which components are for what job, what the contract is, and what the item number is.”

Previously labels would be handwritten for every part – a laborious task when any given contract could have well over 1,000 individual parts.

“Now the labels are printed automatically, and our laser operative simply peels them off and puts them on the part, so every part can be readily identified on the factory floor.”

For jobs at this scale, Owen adds that the sheer speed of what technology adds to the cutting workflow is what is most astonishing. As he explains, a school [commercial kitchen], which would have previously taken a few days, has taken just 45 minutes.

The increase in efficiency and production rate in the cutting operation has introduced a need for further investment in the factory to stop a current bottleneck at the bending stage.

Shine will shortly be commissioning a third press brake to fully benefit from the increasingly fast rate that the flat components are coming off the laser bed.