The design of the Lelo Sona sex toy was driven by the urge to create an entirely new kind of sensation for customers, based on sonic waves rather than simple vibrations. We report on how the Swedish firm translated that innovative thinking into an award-winning product

What do you buy the sophisticated woman who seems to have everything but still wants more, as a gift to mark her 50th birthday? That was the challenge facing three Swedish designers/engineers, which led to the development of luxury sex toy brand Lelo back in 2003.

Contemporary designs lacked innovation and luxury, the trio observed. The adult stores in which they were sold lacked comfort and intimacy.

With their background in the development of early smartphones and their expertise in navigating how the technological and the personal can come together in a compelling product experience, their work began in the front room of a Stockholm townhouse with one simple question: “What if our most intimate items were made as beautiful as the ones we displayed with the most pride?”

Their first design – the Lelo Lily – far exceeded expectations in terms of its considered design, its simplicity and its technology, says Stu Nugent, the company’s brand expert: “It went against everything else on the shelves at the time, resembling something more like a smooth pebble from a Nordic fjord than a phallic sex toy of convention.”

The gift’s recipient, meanwhile, was thrilled. At her insistence, the engineers put together a handful of further prototypes and began touring trade shows with their designs.

Word spread, and as interest in the Lelo Lily grew, it quickly became unviable to make each product to order.

Demand grew for follow-up products. An increasingly large and sophisticated distribution network was needed to get those products to eager customers.

Fortunately, the team’s earlier experiences in the technology industry provided solid foundations for growth.

Today, almost two decades on, Lelo’s heart may still be very much in Stockholm, but it now has a presence in locations around the world, from San Jose to Shanghai.

A multicultural brand from the start, it operates as a highly internationalised, decentralised business. Digital operations, for example, are run out of its offices in Zagreb; manufacturing happens in China; and business-to-business sales are largely an American affair.

Lelo – sensational detail

Despite an established reputation and popular products, Lelo still works hard to find room for innovation. And what that comes down to is close attention to sensory and anatomical detail, explains senior product development specialist Juanita Salcedo. “We’re interested in sensations. That might sound obvious given the nature of what we do, but just as you need engineers of sound and light to produce a beautiful movie, so you need an engineering approach to sensation to make something sensational.

The vast majority of pleasure products available, including those built by Lelo, involve the creation of pleasurable sensation through the stimulation of nerve endings by vibration.

“Vibrations are great. We love them. But that doesn’t stop us wanting to explore entirely new, untapped territory,” she explains.

“We wanted to find out if there was an entirely different way to approach those sensations, and to do that, we had to understand how sensations are created and interpreted.

So for a new product, Sona, the starting point was something entirely intangible. “Not a new design, not a new shape, not a new audience, but a new feeling. From there, we quickly made the leap from vibrations to sonic waves, based on the physical impulsion one feels in the presence of a powerful kind of energy. In this case, sound, in a sense.

Naturally, some designs are led by anatomy and there’s no escaping this simple fact. “A penis ring, for example, is always going to be the shape of a penis ring,” states Salcedo. But the team’s experimentation and increasing understanding of anatomy has led to some interesting product developments.

“The clitoris, for example, was long held to be a bundle of nerve endings atop the entrance to the vagina,” she explains. “But now, as poorly publicised as it is, we know that the clitoris is a far more substantial structure, extending its ‘legs’ around and into the vagina, and perhaps buttressing the G-spot.

“In fact, research suggests they might be one and the same thing.” She adds: “Isn’t it crazy that there’s still speculation about such a thing? It’s a testament to the unforgivably poor state of research into female pleasure processes.”

This is where Sona differs from most competing products.

Instead of vibrations that simply stimulate the nerve endings closest to the skin’s surface, it’s based on sonic waves, so that sensations are transmitted along the entire structure of the clitoris.

Lelo – from sensation to hardware

According to Salcedo, Sona’s ideation and development may have been the firm’s most conceptual to date, but they have also proved the most seamless.

“The idea of sound, sensation, and pleasure all came together at exactly the same time, leaving us with that ‘Why didn’t we think of this before?’ feeling that we all enjoy as designers, because when you feel that, you know the idea is strong. ”

Lelo’s development process follows a pretty typical route. Ideas are workshopped in a product development meeting, with sketches flying around, amendments being added and modelling clay manipulated into suggested shapes, until the assembled team have settled on a rough design that suits the original idea.

With a previous product, Soraya, design impetus came directly from customer comments on social media and feedback from shop assistants on market trends. Demand was identified for ‘rabbit-style’ vibrators, the technology required was developed, the silhouette designed to encompass mechanics, and the design tested and refined.

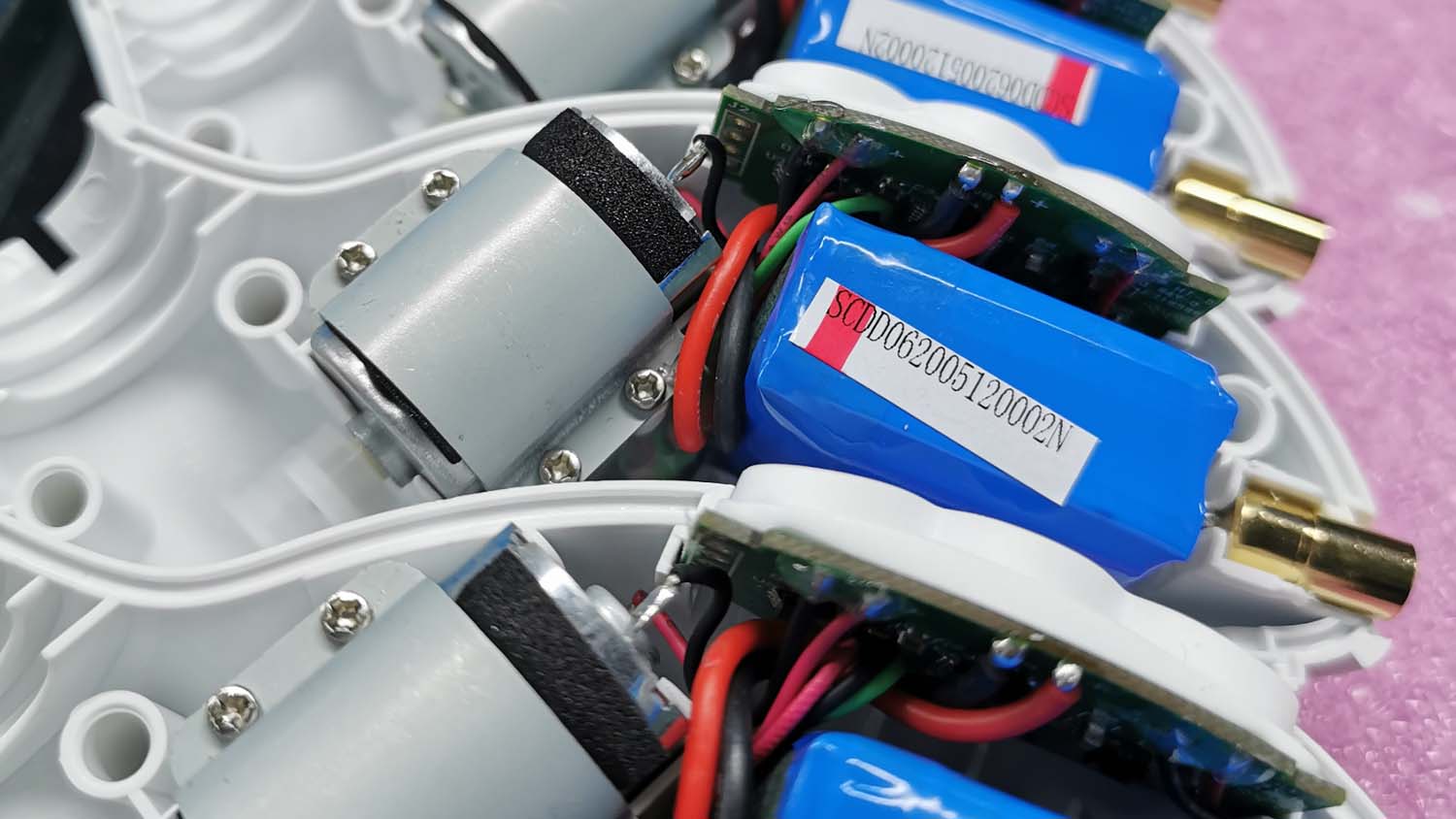

With Sona, however, the design impetus was the search for entirely new sensations. That triggered a particular mechanical engineering challenge: while the team was familiar with using unbalanced rotary motors to create vibrations, now they would be dealing with miniaturised sonic motors.

Eventually, the archetype they settled on was the cone of a subwoofer: they took that oscillating principle and applied it through a silicone surface on a much smaller scale, to create a sense of ‘bass’ that could then be applied directly to the body.

Developing Sona’s Cruise Control function – from which the upgraded Sona Cruise takes its name – was even more complex.

As Salcedo explains, “That functionality allows the oscillating motor to retain a set amount of power over and above normal operation. When the motor senses that it’s begun to experience high resistive load, [it] adds the power it was keeping in reserve, to maintain a consistent sensation no matter how vigorously the product is being applied.

“We wanted to eliminate the kind of power drop that characterises many lower-end pleasure products, and we achieved it.”

Of course, internal mechanisms are just one aspect of the challenge when dealing with devices that come into intimate contact with the body. External form plays a vital part, too, in terms of both aesthetic qualities and function. But according to Salcedo, the Sona’s form development proved less challenging than for many other products.

“It all happened together, really. Each element of the development necessitated an adaptation to the design, and the design adaptations necessitated certain functionality,” she says.

“I hate to say it, because it’s a very unsatisfying answer from a designer’s perspective, but Sona kind of designed itself. We trialled a number of different design applications, but in the end, we sort of trusted it to dictate its own direction, and the end product was very close to the way we thought it might end up anyway.”

She continues: “Sona’s shape happened fast and naturally: we had the engineering principles of a subwoofer in mind during development, so it’s no coincidence that the clitoral aperture is cone-shaped.

“Similarly, we knew we were targeting the clitoris specifically, so we had to work within the framework set by anatomy. And third, we had to apply our knowledge of how the product would be used – onehanded, not to put too fine a point on it. Sona’s ergonomics were dictated by that.”

3D design tools usually come into play around this point. Lelo uses a mix of McNeel Rhino and PTC Creo, with disparate teams focusing on their given area of expertise.

A number of 3D renders will be produced and 3D printed in time for the next development meeting.

There, various designs will be considered, in line with the advancements the engineering teams have made in their own research. It’s all very symbiotic, and it’s all done in-house, from start to finish.

The engineering team has access to full-size, industrial 3D printers for high-quality prototyping, but there are also a couple of Raise3D FDM machines in the offices too, for quick and dirty ideation.

Integrated Production

Manufacturing happens in China, but not just for economic reasons. The team at Lelo claims the company is unique in its industry in keeping most of its processes inhouse and derives major benefits from that decision.

As Nugent explains, “We wanted to be able to produce extremely luxurious pleasure products, but make them in a way that they could be accessible to most budgets.

“We also wanted to reach beyond a western audience, and bring what Lelo offered to everyone, not just the US and Europe. So, we moved the entire design and production operation to Shanghai, while maintaining operational headquarters in the US and Europe too, expanding from there.”

Much of the company’s research and development now happens in Shanghai, which hosts a large multinational team of designers and engineering, steered from the top by one of the original founders, Filip Sedic. It’s in this office that the real graft of the design work happens, fed by data and input from the global team.

Taking in the various engineers and designers involved specifically and only in product development, the team extends to around forty people, half of them western and half of them Asian, with a more or less 50/50 gender split, too. Says Nugent: “A lot of senior responsibility holders are women, and the majority of marketers and PR specialists are women too. The company has a good representative mix, reflecting its incredibly diverse customer base.”

The skills at work are diverse, too. In-house teams design the manufacturing equipment itself, often from scratch, such as the molds and manufacturing processes used to make the company’s Hex condoms.

In fact, these production teams are involved from the start of a project, advising on which elements might add significant cost to the design, and what amendments might be made to reduce cost without affecting performance.

“We have the ability to do all this very fast, since our manufacturing facilities are only an hour away from our design studio and head office,” says Salcedo. “The transition from design to production is the responsibility of a director who has been consulted and involved since conception – and, in the case of Sona, is largely responsible for the original idea. So for Lelo, the transition is a smooth and natural one.”

Being able to rely on its own in-house capabilities, she says, saves huge amounts of time and cost, not to mention the frustration of agreeing and monitoring service-level agreements with an outsourced manufacturer, as many competitors must do. “It’s no trouble at all to have the person who 3D-rendered the design in the office visit the factory, consulting with the people who will make it.”

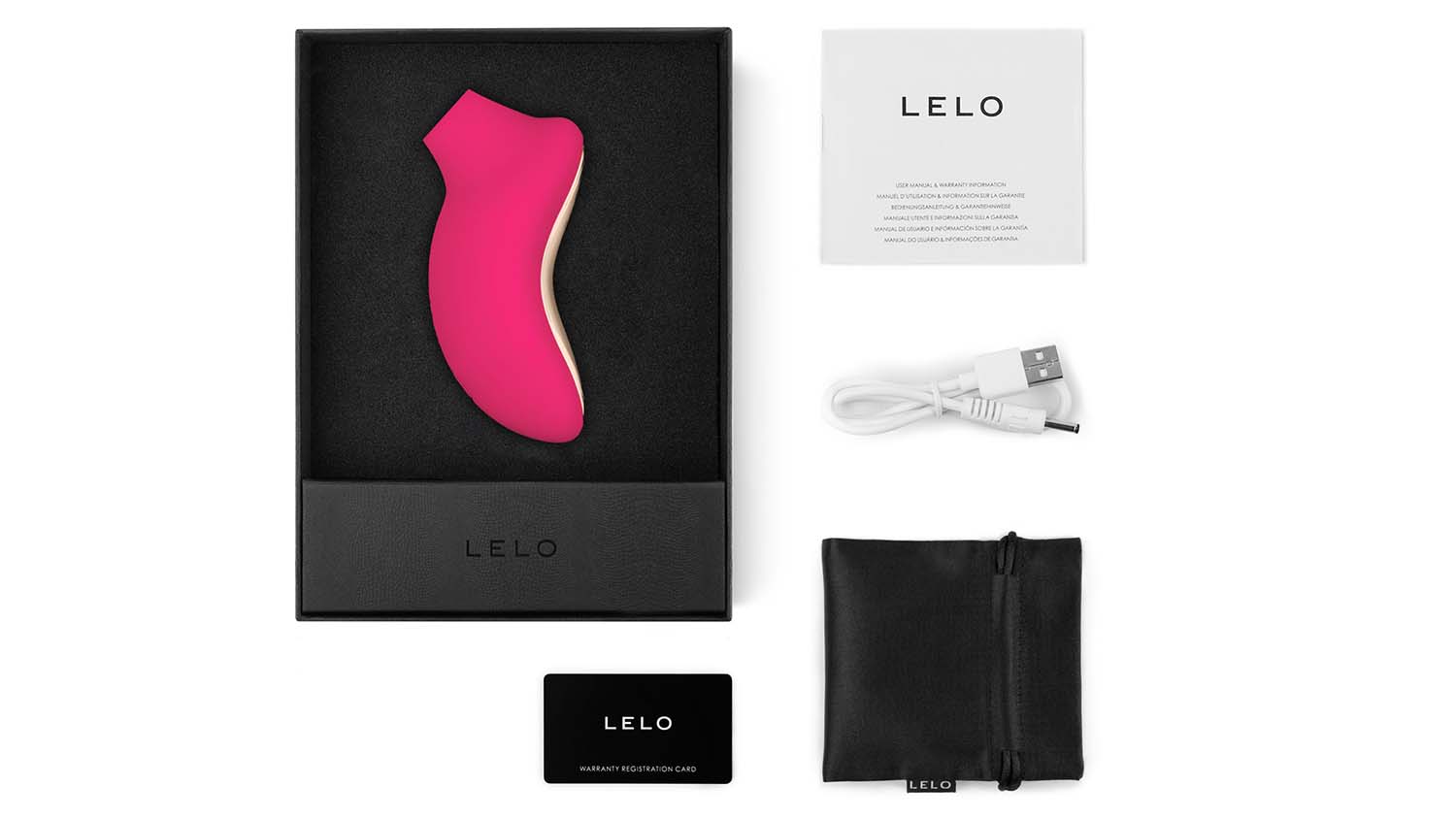

Introducing Lelo Sona 2

The Lelo Sona was released to great public acclaim and five-star reviews. Lelo has since followed up with an updated version. The Sona 2 features different pressure settings, as well as a redesigned exterior.

Considering the industry Lelo operates in, you might be forgiven for thinking that customer feedback might not be immediately actionable as design changes or new engineering challenges. But that’s not the case at all.

Salcedo explains that Sona 2’s updates were largely based on reviewer feedback, collected over the original version’s first two years: “This might come as a surprise, but there is a huge, vibrant and highly vocal community of committed sex toy testers, who have no hesitation in providing detailed and experienced feedback on their experiences.”

She adds: “Many of them now do it as a profession, or at least as a healthy second income. Very often, this feedback is given to us openly, particularly by Twitter.

“By aggregating all of their responses and analysing them, we’re easily able to spot patterns and places for improvement.”

Take, for example, the clitoral ‘cone’; thanks to feedback from reviewers, the Lelo team realised that making small changes to its design could significantly enhance the range of sensations – so it did so.

Into the future

As with all industries, the production of sex toys is intrinsically linked with other, seemingly unrelated areas of technology and the Lelo team is very open to new thinking from such sources.

As Nugent explains: “The digital revolution and advancements in connectivity will undoubtedly drive innovation in the sexual wellness and intimacy industries, as they do elsewhere. In fact, one particularly fast-growing section of the market, into which Lelo falls, is now referred to as ‘sextech’, even by mainstream outlets, and so the pace of progress accelerates as old taboos are washed away and new developments embraced.”

He fully expects sex toy apps to grow in sophistication and increasingly integrate with the Internet of Things (see below), “to such a point where a pleasure product will be able to deduce, through a series of algorithms based on your use of it, exactly what sensation you want, before you know it yourself.”

These kind of learning programmes already exist in the industry, to an extent, he says; take, for example, the proliferation of intelligent sex dolls in the Far East. “With virtual reality now coming to maturity, it’s easy to see applications for that technology in the very near future, creating and exploring fantasy in real time.”

New production methods and materials are on the horizon, too. For now, Lelo relies on a handful of tried-andtested materials that it knows unequivocally are body-safe and feel great, in line with regulations for the medical industry: cured silicone, ABS plastic, stainless steel.

But it is also interested in the ‘supermaterial’ graphene, while conceding that, for now, it’s not commercially viable. “We costed it: it would cost $15,000 dollars per condom,” says Salcedo.

“But we always have our ear to the ground: with graphene just around the corner, and the fantastically organic nature of carbon nanotubes, the next generation and the one after that will be the most exciting in history.

“In the meantime, we’ll concentrate on engineering entirely new sensations using the materials we know work best.”

With over 17 million products shipped and numerous design awards under its belt, the main focus begins and ends with the customer. As Salcedo puts it:

“I think what’s driving most advances in the manufacture of consumer goods is the consumer: more than ever, and across every industry, consumers have become much savvier about quality, much better equipped to make educated buying decisions, and much more vocal with the brands they’re buying from. If anything, it’s the quality of the consumer that’s changed most – and for the better.”

Connected pleasure: What does the future hold?

Intimate devices are becoming much more intelligent than a switch, a battery, a motor and an eccentric cam. We wanted to know how the Internet of Things (IoT) and the widespread ambition to connect everything is changing Lelo’s design process, if at all?

Does the team consider connectivity and intelligent operations as an equal part of the design process or are they considered separately?

“Our processes have a certain amount of flexibility built into them, constrained only by anatomy, so it’s hard to even define our process with any certainty,” says Lelo’s Juanita Salcedo. “It’s that way necessarily.

As taboos are shattered and the sexual landscape changes, we need to have that flexibility in order to maintain our relevance, in all sectors of the business. It’s rare that a technology or material emerges that forces a change in whatever process we already have,” she explains.

That said, characteristics such as intelligence and connectivity are certainly considerations to bear in mind.

“Indeed, many of our products integrate some kind of wireless functionality by design. But we tend not to rely on it too heavily. What customers desire most is simplicity.”

In fact, it could be a long time before you encounter anything resembling an operating system built into a Lelo product, she adds, “because in a product as personal as a Lelo, a clever interface is actually an obstacle for a user, not a benefit.”

It’s not unimaginable that Lelo will do it in the future, and it’s exploring those avenues, she says, “but we focus more on streamlining the user experience as much as possible, not complicating it.”

“Despite the relative complexity of some of our technology, the trick is, as many of your readers can probably testify, to make it look simple.”