Joyride Design’s ‘responsive furniture’ uses bespoke mechanisms to transform from compact to comfortable, using only the bodyweight of the sitter. We take a look at the company’s design process and the role played by PTC Onshape

The world is not exactly short of chairs, notes James Lucas, CEO of East London-based furniture company Joyride: “I would imagine that the chair is one of the most designed objects on the planet. There’s a lot of them!”

What the vast majority of them lack are the responsive elements that Joyride strives to incorporate into its products. For Lucas and Joyride, responsive furniture for the office and home should save space and use clever mechanisms to transform compact stools into more comfortable seating with backrests.

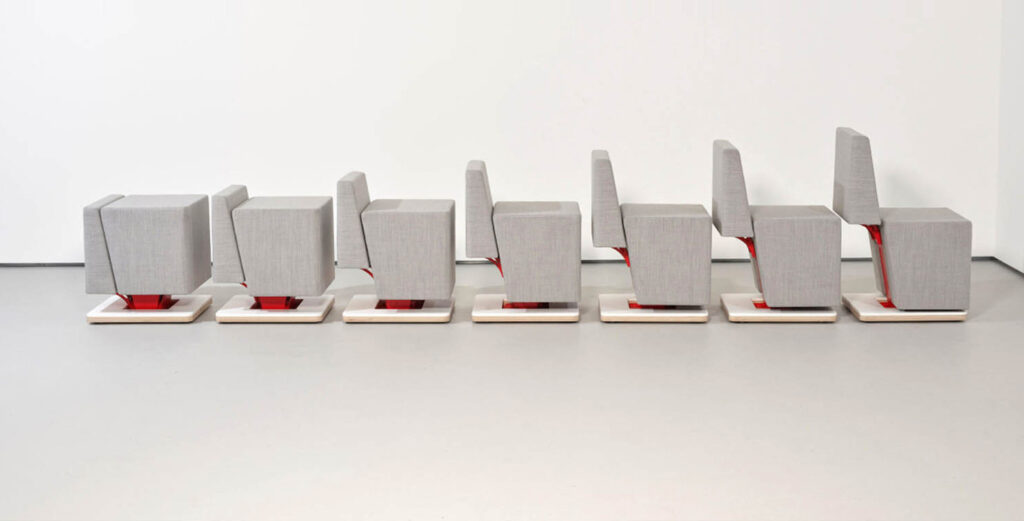

While Joyride’s design process has a lot in common with those associated with traditional furniture – ergonomic considerations, comfort, materials – the end results owe much more to mechanical ingenuity. When a user sits on Joyride’s Cuba chair, for example, the cushioned stool responds to their weight, causing a backrest to rise up to offer extra comfort and support.

The design was spawned from frustration, Lucas explains. A large office chair takes up too much space and the backrest only has a purpose when the seat is occupied. “From all my engineering experience and my love of transfer of movement and creating efficient systems, [I thought I] must be able to tap into this energy. This initially was what, and still does, excite me about it – the energy that’s wasted every time we sit down.”

Clear concept

The concept for Joyride was clear: to do something fun, inspirational and practical with this energy and tackle office ‘chair management’. “If you have a stand-up meeting, typically, all the chairs end up around the outside of the room, and it’s just a pain in the arse,” says Lucas, and when anything’s a pain in the arse for most people, it just doesn’t get used.”

Coupled with a height-adjustable table, the Cuba seats offer several configurations that outstrip traditional desk furniture, docking against the bottom of the table base when not in use.

Cuba began as a clean-page design, rather than an evolution of an office chair, with the initial design quickly decided upon in little over a month. The concept won an award, with part of the prize being the chance to exhibit it at 100% Design, a trade fair for contemporary interior design in London.

This left Lucas with only five months in which to make the design reality. “I had 50 in production within that time,” he reflects, “and only around two were ready on the morning of the show. It’s good having hard deadlines sometimes!”

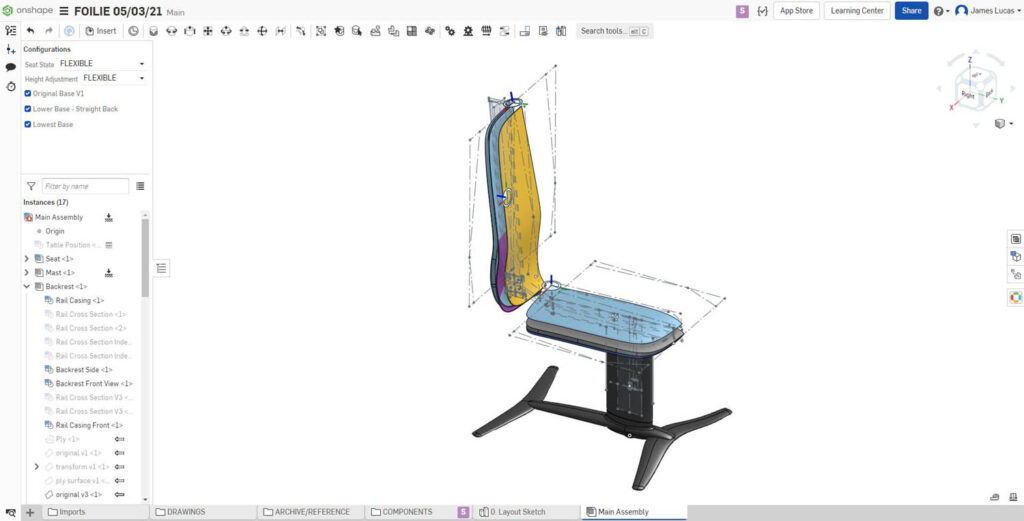

The key challenge proved to be perfecting the mechanism, ensuring that the requisite parts line up at the correct heights. “You’ve got a lot of constraints that you need to map out quickly and efficiently and we’ve now developed a process with Onshape,“ he says.

The team worked with PTC reseller and training partner Concurrent Engineering to uncover features in Onshape that would enable flexible working and collaborative designing.

“In Onshape, we all worked on the same document – we called it the Master Sketch – which drives everything and usually sits in the 3D model. We don’t necessarily extrude directly from the Master Sketch, because it can get a bit messy, but it’s there for reference and we can constrain things to it. Then it starts building out into 3D.”

The mechanisms are key to the product, Lucas jokes, because if they don’t work, “it’s not a piece of responsive furniture, it’d just be a rather heavy stool!

While other mechanisms exist in the furniture industry, he adds, they’re nothing like Joyride’s. “They don’t use a sliding system. They’re not made in the same way, so that has been a huge challenge, because a lot of stuff that we use in the mechanism is not used in volume products,” he explains.

The style of mechanism that Joyride uses is more akin to those found in automation and manufacturing equipment, like CNC machines, to produce glides and slides.

Lucas says: “You’ve got a lot of restraints with responsive furniture, so you’re more limited, but we take a lot from what already works very well in the furniture industry.

“The complicated bit is making a reliable mechanism that goes up and down, and that doesn’t chop your kid’s fingers off. You’ve got to think about all these squeeze and shear points. It’s got to be a really nice experience.”

Joyride – A sit-down success

When 3D CAD designs are considered advanced enough, Joyride begins to work with its suppliers to get important feedback from them, including costs, tolerances and occasionally something the design team might not have considered.

“For example,” says Lucas, “we wanted to get some of the seats moulded for the Cuba product, and the more we learned about that, the more we realised the foam needed more area to flow around the mould.”

These kinds of lessons are typically through more runof- the-mill productivity apps. “The more we can be doing that in a Google Docs style the better. Then we’ll reflect on what people have said, adapt the design and keep moving forwards, with different [team members] working on different part areas.”

The team at Joyride is now in the early stages of sending stakeholders Onshape links to view files. “It’s definitely the way forward,” says Lucas, adding that he’s excited for other future features in Onshape that will help streamline his company’s design process even further.