When it comes to reducing vibration in power tools, so that workers avoid the risk of developing hand-arm vibration syndrome, Hilti has some clever testing tricks up its sleeve

For workers operating power tools, long periods of usage come with a real risk of developing hand-arm vibration syndrome, or HAVS.

This condition is associated with damage to blood vessels, to nerves in the fingers and to bones and muscles. As well as duration of exposure, the magnitude of vibrations is a key factor in the development of HAVS. As such, vibration is an important health and safety concern – as is the noise pollution generated by vibrating tools.

For equipment manufacturers, meanwhile, it’s often not possible to eliminate vibration entirely, especially from tools that generate vibrations in order to fulfill their main purpose. But in many cases, there is much they can do to lower them through improved design and engineering.

Take, for example, the TE 3000-AVR concrete demolition hammer; made by Liechtenstein-based Hilti, a leading supplier to the worldwide construction and energy industries, this too features active vibration reduction (AVR) technology, which makes the tool less tiring to use, boosting operator productivity.

That’s an important step forward. A large hammer drill without any anti-vibration measures incorporated into its design may vibrate at a level of between 20 and 30 metres per second squared. But efficient vibration reduction technologies, combined with extensive testing, can result in a design that reduces this to below 10 metres per second squared, boosting permitted use time to two hours per day. That’s a 300% increase.

In order to accurately analyse vibrations transmitted to the human body and ensure its tools get certified according to internationally recognised standards, Hilti relies on the human body vibration filter add-in found in Simcenter Testlab from Siemens PLM. The application gives real-time feedback and clearly indicates limit values and/or violations, as specified in the ISO 2631 and ISO 5349 standards from the International Organization for Standardization and the European Normalization (EN) 60745 standard.

Hilti – testing the demolition hammer

Prior to the testing needed to achieve certification, the TE 3000-AVR, like other Hilti products, underwent a series of other comprehensive tests designed to shorten the product development cycle and meet market demands for longer product lifetime, enhanced reliability, high performance and low weight.

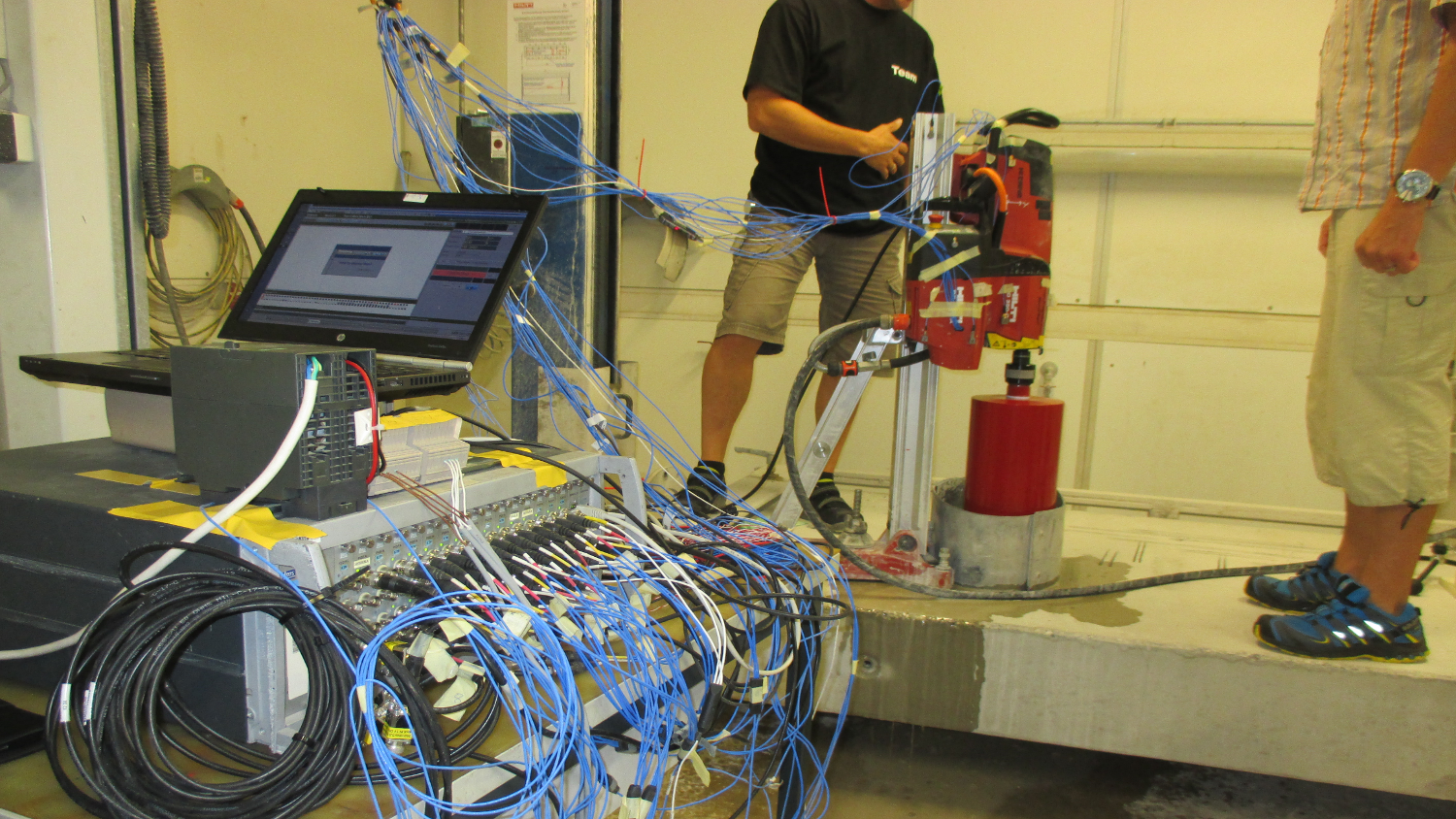

It’s at the Hilti Competence Center for Health & Safety Technologies in Kaufering, Germany, that group manager Lars Melzer and his team are tasked with putting newly developed tools through their paces.

“There are two ways of qualifying new developments: the full system tests and the component tests,” says Melzer.

“We make use of the testing hardware and software offerings in the Simcenter portfolio to perform these tests in an efficient and reliable manner.”

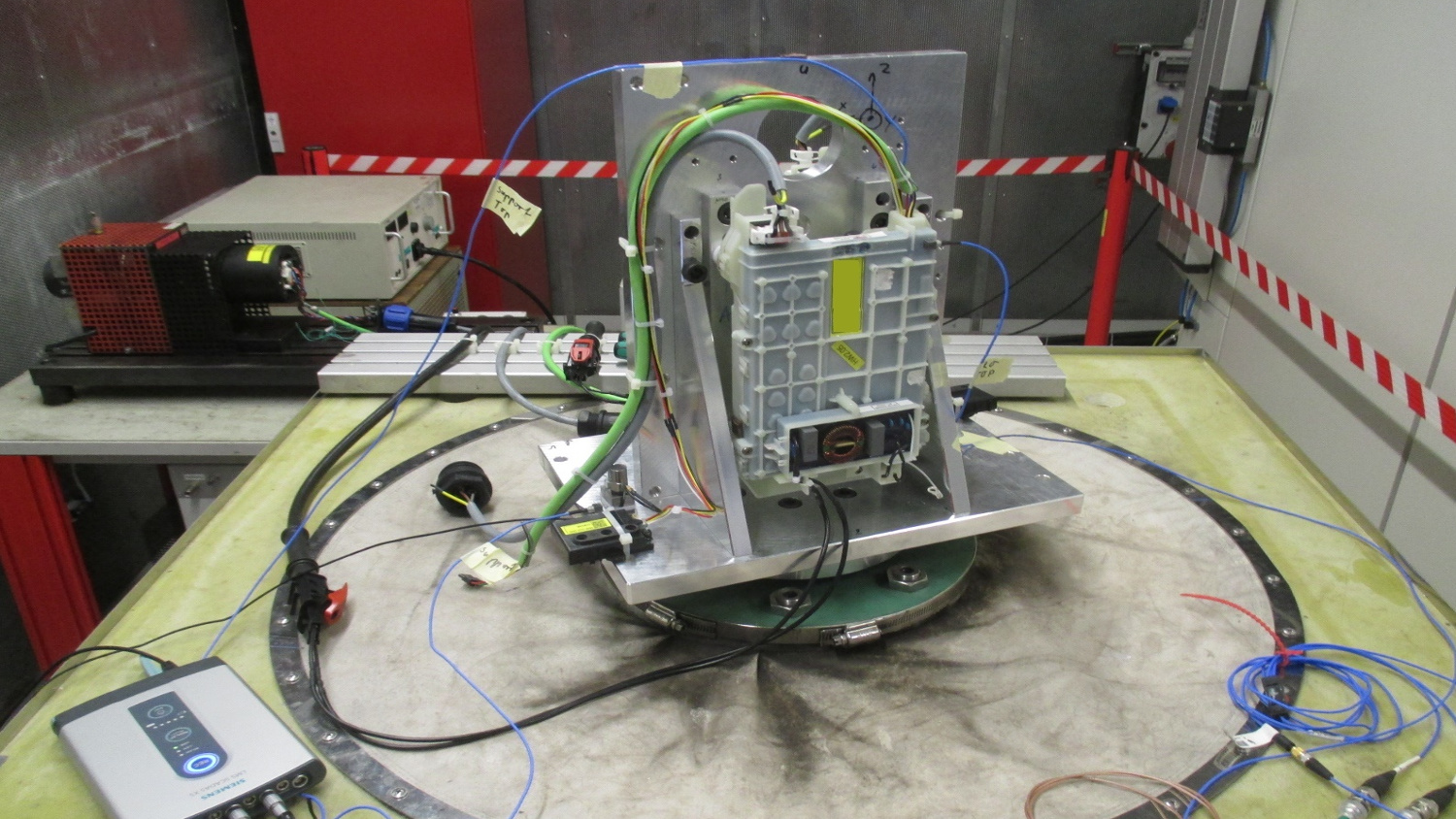

In a system test, a complete, functional power tool is tested according to its real-life applications. The test procedure reproduces simplified load cases collected on artificial work pieces. A component test, meanwhile, focuses on a single component, such as a switch, electronic assembly, battery interface or motor, which is isolated from the power tool. Component tests are performed on test rigs or shakers.

Shake it until you make it

Component tests require shorter amounts of time, are less costly and can be executed even before the first prototype or tool is available. They can be performed in wellcontrolled conditions and allow for additional monitoring of environmental parameters (such as temperature, dust levels and so on). To ensure the high quality, reliability and efficiency that characterises the Hilti brand, shaker tests require a clear process.

This begins with acquiring data using Simcenter SCADAS hardware and Testlab Spectral Testing software. Hilti engineers perform an analysis on the data, using the Simcenter Testlab Signature acquisition capabilities, to better understand the component’s vibration behaviour.

Simcenter Testlab Impact Testing then helps the team perform accurate shaker test set-up. Simcenter Testlab Mission Synthesis is used throughout the shaker tests and validation process. Finally, the data is stored, managed and shared in an interactive, graphical manner, using the Simcenter Testlab Desktop application.

According to Matthias Patalong, a development engineer on Melzer’s team, “Simcenter helps us set up quick and reliable component tests with minimal effort. All necessary functions are integrated within one software solution, making data conversion unnecessary.”

Well-defined and harmonised

To get an understanding of the dynamic behaviour of the system in the first phase, the team relies on the broad range of structural testing and analysis capabilities available in Simcenter Testlab. These include impact testing, operational deflection shapes (ODS), experimental modal analysis (EMA) and operational modal analysis (OMA).

These tests and analyses allow the team to identify potential damages and plan the mounting conditions of the device under test or the test specimen on the shaker. As Claudius Lein, a Hilti development engineer, puts it: “Understanding the dynamic behaviour of the system is mandatory for setting up high-quality shaker tests.”

In the next step, the team performs vibration measurements. The engineers use Simcenter Testlab Signature Acquisition and Spectral Testing for defining and executing several tests corresponding to various applications and load cases. Simcenter SCADAS is then used to acquire data that generates representative shaker profiles. The selected parameters for the load cases consist of a combination of tool, user, workpiece, insert (such as a drill bit) and feed force.

Hilti – perfect fixture design

As Susann Nönnig, a Hilti development engineer, explains: “Adequately stiff shaker fixtures are essential for highquality tests.” For fixture design, Hilti relies on tools from the Siemens Digital Industries Software portfolio, including the CAD module in NX software, as well as numerical analysis and physical testing tools from the Simcenter portfolio.

The process starts with designing the fixture using NX CAD. From there, performing a numerical modal analysis using Simcenter 3D is only a step away. The fixture design is iterative and conducted through active collaboration between the design and simulation teams.

The software suite available in the Siemens portfolio supports effective communication between the different teams. The iterative process ensures the fixture meets all set requirements prior to manufacturing.

Once a fixture is manufactured, the team then performs the required physical tests and analyses to validate its design; namely, experimental modal analysis and ODS analysis. With validation completed, the physical component test can then be performed. The test item and its fixture are placed on the shaker and instrumented. The testing team feeds the defined test signal to the shaker, determines the frequency limit for the test and adapts the signals if required.

One of the main benefits of performing shaker component tests is that other conditions can be assessed simultaneously. For example, a dust chamber can be placed on top of the shaker to simultaneously test sensitivity to concrete dust. Other test types may combine vibration with electrical load or climate, for example.

Thanks to its well-defined procedures, Hilti’s engineering team can ultimately save on testing time, while ensuring products meet the requirements for superior quality and durability, while safeguarding operators and users.

Melzer concludes: “Simcenter is necessary at every stage of component testing, especially during preparation, to ensure high test quality. [It] definitely makes our business more efficient.”