Nowadays it’s not uncommon to hear of a Western product design consultancy setting up an office in China.

IDC Models provides a prototyping and model making service to a range of clients including BAFTA

Often the purpose of this subsidiary is to be on the ground, liaising with the Chinese suppliers who will be manufacturing the products for the consultancy’s Western clients. However, Industrial Design Consultancy (IDC) is different.

Although this Berkshire-based consultancy has a subsidiary in Shanghai its purpose is to actually provide a design and product development service.

“As a country, China’s reputation has been as a manufacturer. But we recognised a growing opportunity for input from Western product designers like IDC, to create designs specifically for the Chinese market,” explains Stephen Knowles, IDC’s managing director.

“We all know that China is the number one exporting country but the fascinating dynamic now is that it’s the fastest growing consumer market. All these middle-class Chinese are looking to buy products and consume.”

Although IDC China was only set up two years ago, the consultancy has been working for Chinese clients for over five years.

The catalyst was in 2007 when IDC was selected to be part of UK Trade and Investment’s ‘China Design Workforce’, a selected group of design agencies equipped to gain a foothold in this rapidly developing market.

“As well as the trade mission I also did my own trip down to the South of China. I drove from Shenzhen, which is just across the border in Hong Kong, and for two to three hours I just passed factory upon factory. There is just so much industry and manufacturing,” comments Knowles.

“It really made me realise how the nature of design in the UK has changed. Whereas in the past where all design and engineering happened in the UK, increasingly in some sectors, more of the design as well as the detailed engineering is done in China by the OEM companies that make products for the big manufacturers. It made us think that there is a lot of design that will need to be done in China and that will only increase. So we made the jump.”

Lost in translation

However, working for Chinese clients does present an array of challenges with the language barrier being the obvious initial stumbling block.

Although the larger companies do have English speaking staff or use translators, IDC felt it was important to have somebody who had local knowledge and so employed a Chinese agent who was instrumental in helping them set up.

Knowles also felt as he was going to be doing business in China he’d learn the language and so he went to Mandarin lessons. “Of course we do still need a proper translator but it’s useful to break down the social barriers through informal conversation,” he says.

As IDC had built a reputation for medical device design in the UK, that is the product area it would initially focus on for Chinese clients.

“China is such a big country that with a relatively small office you can get distracted chasing around in a lot of different areas. We have a strength in medical products and so we thought that would be the most sensible thing to focus on.”

This decision was reinforced by statistics which confirm that China is the second largest healthcare market in the world and trade in medicines and healthcare products are estimated to grow by 24% per year.

It didn’t prove too challenging to find clients as there is a strong demand for high end design in China.

Although employing Western design consultancies is often far more expensive than the Chinese ones, which there are a few of, Chinese clients feel they have more to gain in that Western design consultancies have a reputation for quality design and also have an awareness of the marketplace, which is important as many Chinese companies want to launch their products globally.

New ways of working

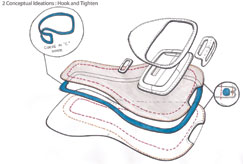

However, IDC soon discovered that working with Chinese clients meant a different way of presenting concepts.

“The Chinese consultancies specialise very much in doing highly rendered concept stuff, which actually looks like the glossy rendering we’d present at the end of the process,” describes Marc Tanner, IDC’s head of industrial design.

“Once the client has seen the rendered concept first, it reassures them that you’ve done some thinking about the product. So rather than the usual chronological or linear pattern of discussing the initial research, user studies and background thinking of the design first, you sort of have to do it backwards.”

One of the first Chinese clients IDC worked with was Shenzhen Xunfengtong (XFT), which was keen to develop a family of products that could compete on a global stage in functionality, quality and design, as well as branding.

The first product was the CPR Assistant, a device that a patient rests their neck and head onto. Through a combination of visual and spoken life-saving instructions, it aids the person administering CPR. Additionally, a metronome helps with the timing of the compressions.

The CPR Assistant has been very successful for the client and even went on to win the prestigious China Red Star award.

As Knowles explains, reputation is very important in China. Once trust has been established, repeat work will often follow and introductions to friends and colleagues can bring new opportunities.

IDC has not been short of work and over the past five years it has designed and developed a number of medical devices including a Suture dispenser, anaesthetic pumps, lancing devices for glucose blood measurement as well as a number of medical disposable projects.

In that time IDC has also done four products for XFT with the most recent being the Foot Drop System.

This system includes a small Functional Electrical Stimulation (FES) device, which is strapped onto the patient’s leg below the knee, and sends electrical signals to the peroneal nerve (the nerve that controls the movement of the ankle and foot) to counteract the effect of foot drop in patients with neurological problems.

The FES works in combination with a foot sensor, which detects the walking rhythm and helps regulate a normal walk.

For this project IDC handled product development from concept right through to production support. It carried out patient as well as doctor research and then produced several prototypes in a variety of materials, before the look and structure were finalised.

“Combined with IDC’s excellent design, we have turned this FES device into a high-tech advanced machine. We already have SFDA certification in China, where the product has been used in more than ten cities. We are now ready to apply for CE and FDA certification, for sales across the world,” says XFT’s product development manager, Jackey Woo.

Office expansion

Setting up an office in China has proven to be a good strategic move for IDC but it was risky and did require a lot of time and money to get it up and running.

“It’s a big commitment setting up a company because the nature of doing business in China is quite bureaucratic: once you’ve set up an office you have quite a lot of administration overheads, regulations that have to be abided by, accounts that have to be filed monthly and tax etc.

So you have to have quite a few people there to justify all that expense,” comments Knowles.

Although only two years in, IDC China has already doubled in size. There is a mixture of British and local staff including a new recruit – a Chinese native industrial designer, who has spent three years working in US design consultancies.

Of course there is another side to the China office too and that is providing a service to UK or Western companies who need help in sourcing and setting up a Chinese supply chain or who want to develop products for sale in the rapidly growing Chinese domestic market.

“For UK clients the fact that we can make things for Chinese companies is not a big advantage but the fact that we are over there and can help get projects facilitated faster and smoother and also show them where cost benefits exist, is a big advantage.

Additionally, we are increasingly being asked to adapt Western products to suit the different requirements of the Chinese market,” says Knowles.

Back in Blighty

Back in the UK office in Berkshire, alongside its consultancy business, the past few years has seen IDC create its own Lifecycle Assessment (LCA) Calculator, which has proven so popular with a number of clients including Jaguar Land Rover that it is now a separate entity (lcacalculator.com), as well as the recently launched graduate training scheme for new engineers.

In terms of consultancy work, although much is in the medical field, IDC does get involved in a broad range of projects from a SuperSkin motorcycle Helmet and new spectrometer accessories to inflatable solar panels and street lighting.

With all the facilities in-house, IDC can take a product from very first concepts all the way through to production. One such example is the laryngoscope for the Venner Group, which is a device used during general anaesthesia or CPR to introduce an endotracheal tube through the vocal chords.

“Basically, the clinicians had the idea for the product and we became their R&D department,” describes Knowles.

“We did the full development from talking to the clinicians as well as patients and then working out exactly what was needed in terms of technology, how we’ll engineer it, setting up manufacture through to certification and approvals. It’s great when you get that involvement and ownership of it all especially as it then went on to win a Red Dot Design Award.”

Under one roof

A major advantage for IDC is having prototyping facilities in-house including a Viper SLA machine, spray booth facilities, vacuum casting and four CNC machines, one of which is brand new.

“The benefit of having it on-site is that if there are any questions or problems, you just walk upstairs and have a look and make a decision. So, it offers a lot of speed, efficiency and reliability,” says Knowles.

In fact, IDC Models is a separate division offering prototyping and model making services as well as low volume manufacturing to a range of clients. For instance, a recent project with Imperial College involved the prototyping of a very small robotic pill.

The pill, which measures just 30 x 11 mm with minute robotic components inside, is swallowed by the patient and then tracked by the doctor.

When it reaches the small intestines the medication is injected into the targeted area. On the other hand, IDC Models has a long standing relationship with a casting company that utilises its finishing expertise in post machining, polishing and assembly of the world famous BAFTA award trophies.

Changing times

IDC’s founder, Mike Woodall, would not have had any of this advanced technology to hand when he set up in 1972. Then designs were drawn by hand using A0 drawing boards.

”When I started my career in the mid 90s it was half drawing boards and half CAD but the CAD systems were so painful that if you just wanted a drawing it was often a lot quicker to get the pencil out,” reminisces Knowles.

“Fifty drawing boards then probably produced no more than the dozen CAD stations we have today. In those days to create anything in 3D you had to draw them section by section and then a pattern maker would sculpt it.”

Tools of the trade

Of course CAD has compressed the design cycles considerably with so much more design now done in the virtual world with new features and capabilities being added to the software all the time.

IDC uses SolidWorks, Pro/Engineer (Creo) as well as Rhino and a few other 3D modellers including Shark and Cobalt from Ashlar-Vellum.

“These odd ball programmes are a lot quicker as opposed to surface modellers like Rhino. But I do have to say that our use of them is fading quickly because of the improvement of tools like SolidWorks, which are now adding rendering and analysis into their offering,” says Tanner.

“But our take on it at IDC is that at the end of the day, CAD is just a tool. They can do amazing things and if you’re not careful, you can get so buried in what they’ll do. We use the tools from the perspective of what will give us the best outcome for the cost and time it will take and try not get too blinded.”

Despite the recent economic downturn, work has kept rolling into IDC and it looks like it’s only going to get busier. As Knowles says,

“What we are seeing at the moment is that lots of companies who put off their plans because of the recession are all of a sudden saying ‘let’s go!’. It’s an exciting time to be developing products.”

idc.uk.com

idcmodels.comi

Why a UK design consultancy is winning business and awards in the Far East

Default