The Power Fist, which is 400mm long, is a close combat weapon designed to give the user superhuman punching power

Fans of the Warhammer franchise and fantasy wargaming in general were no doubt aware that video game developer SEGA was releasing Warhammer 40,000: Dawn of War III earlier this year.

Yet, as well as this niche market, SEGA also wanted to create a buzz around the release in mainstream media too. It decided to do this by giving members of the press an opportunity to wear a reallife working replica of the Warhammer Power Fist.

In the game, the Power Fist endows the Space Marines with superhuman punching power making it easy for them to hammer their way through an armoured tank and tear out the passengers, for instance.

Although SEGA didn’t exactly have that kind of power in mind, it wanted to at least give wearers the ability to punch through a brick wall or a hefty object – such as a toilet.

SEGA – From video game to real life

Creative agency Rewind was tasked with making this fist a reality and while it would create the internals and electronics for the fist, it called upon London-based product design consultancy Luma-iD to create the external housing.

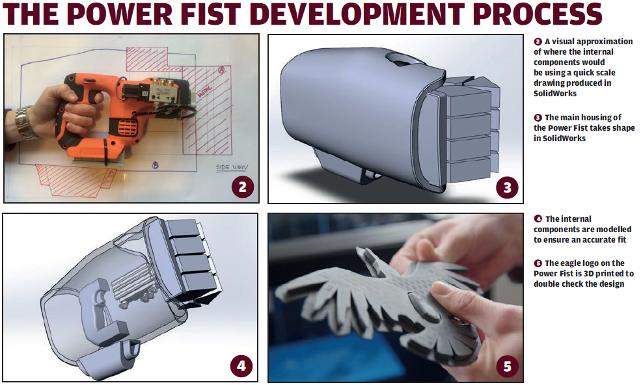

“Rewind had created a visual representation of what the Power Fist was going to look like and our role was to then turn that visual image into a 3D CAD model that could then be made into an actual prototype,” says Matt Passmore, Luma-iD’s product design manager.

“Rewind had already worked out that they wanted to use a pneumatic system and they actually sent over all of the internal components to our studio. So there was a drill handle, a pneumatic ram, a valve control block for controlling the punch and a few little bits of electronics that had to go inside.

“We also got some rough dimensions and basically it was a process of copying what they had created into SolidWorks and then working out how the whole thing was going to fit together.”

The client wanted a rapid turnaround and within a week and a half of receiving the internal components Luma-iD was able to send the completed files to the manufacturers.

The main fist component was sent to 3D Systems Europe, which created the 3D print as a single piece in glass reinforced nylon. Meanwhile the fingers were sent to Proto Labs where they were CNC machined from solid aluminium.

“The lead time for the 3D printing and the metal machining was another three to five days, which is still pretty fast,” says Passmore.

An image-led breakdown of the Power Fist development process – Click here to enlarge image and view full development process

Put the fist to the test

The parts, which together weigh 9.6kg, were then shipped to Rewind for assembly, painting and additional testing.

The challenge was to ensure that while smashing up various objects the wearer themselves weren’t hurt. They would be fitted with a harness with an iso-elastic kinematic camera stabilising platform incorporated into it.

This harness would also hold two air canisters used to power parts from the industrial pneumatic cylinder, which delivers up to 3000 PSI to the Power Fist in addition to the user’s strength.

The press day at Holborn Studios was a resounding success and thankfully no one got hurt. As SEGA head of PR Peter Oliver, says, “The press who tried it out came away with massive smiles on their faces saying how awesome it was to be able to punch through walls and toilets. The coverage was fantastic and that is really what we were looking for.”

Breaking through walls with a real-life Warhammer Power Fist

Default