Using 3DR’s tablet controlled Solo, the user traces a flight pattern on a Google Map and the drone will then fly autonomously over a construction site

Once a plaything of the hobbyist, drones have become increasingly sophisticated in recent years, making these unmanned aerial vehicles (UAVs) appealing to the professional user. And one drone company that has its eye firmly set on the enterprise market is San Francisco-based 3D Robotics (3DR), arguably one of the oldest drone manufacturers worldwide.

This is somewhat absurd as 3DR is less than ten years old but, as we all know, technology in this market moves fast and the company has come a long way in that time.

How it all began

3DR started out in 2007 making UAV kits for the DIY community and soon progressed into creating an open source flight code, which was used to build Pixhawk in 2012.

This autopilot system is today running in more than 750,000 autonomous vehicles.

In 2014 3DR made a foray into developing its own consumer UAVs with the launch of Iris, soon followed in 2015 by Solo, a powerful quadcopter designed with the help of San Francisco industrial design firm Astro that delivers high-definition video from its onboard GoPro camera straight to an app on the user’s mobile device.

Then, in a quest to move Solo’s usefulness from the consumer into the commercial space, earlier this year 3DR launched its aerial analytics platform Site Scan.

The Solo drone collects high-quality data with the Sony UMC-R10C camera

On the road map

3DR’s CEO, Chris Anderson, claims that it was always on the roadmap to move into the enterprise market and that the consumer applications for Solo were just the start.

“I was hired around a year and a half ago with the mandate to build our first enterprise product,” says Dan McKinnon, director of product at 3DR, who himself is no stranger to drones having built an agricultural drone surveying company, Agribotix, with his father whilst at graduate school.

McKinnon initially spent a couple of months with potential customers gaining understanding of the issues they had on site and how these could be solved with drones.

For instance, moving earth around on construction sites is a difficult and often hazardous endeavour. Traditionally, a laser scanner would be used to determine how much earth needed to be moved, but instead a drone can collect all this data conveniently from above.

McKinnon soon realised that a camera-to-app-to-cloud system would be useful to those in construction as well as other industries such as telecoms, energy, infrastructures and utilities who have a need to model, inspect, survey or scan projects.

So, he went about putting a team together to create an enterprise offering.

The resulting Site Scan solution, which was created in partnership with Autodesk, takes images from a job site via the Solo, which is controlled with a few taps and swipes of an app on a tablet (currently, only certified for use with Sony Xperia tablet).

The captured geotagged data is then uploaded to the 3DR cloud where Autodesk’s ReCap reality capture and point cloud software then processes it into an image of the user’s choice, whether that be orthorectified 2D maps, 3D renderings, mosaics, point clouds or 3D mesh.

Once processed, this reality data is available on the Autodesk A360 cloud platform from where it can be downloaded and used by Autodesk software such as BIM 360, InfraWorks 360, AutoCAD or indeed other software tools.

According to 3DR, the process of capturing, tagging, uploading, processing and importing data, depending on the area, is generally a couple of hours.

“We wanted the product to be so easy and intuitive to use that a five year old could do it and I think we were successful. Literally, one button to measure your world and then all the data is seamlessly pulled into our cloud and the Autodesk cloud so you can manage it and generate nice data products like reports or 3D models,” says McKinnon.

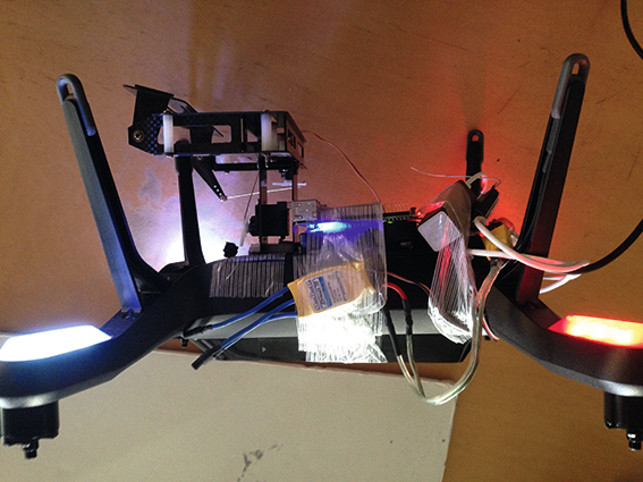

The Solo drone was flying with the GoPro camera however, Dan McKinnon was keen to use a new QX-1 camera from Sony and so prototyped a contraption that connects this camera via software and hard cable to the Solo

New solution

However, McKinnon recognised that although the GoPro is heralded as the world’s best action camera, not all commercial customers would be satisfied with the quality of the images it takes.

“The GoPro is a great camera but there are a lot of limitations with it for professional use.

Extremely high image quality is paramount because the sharper the images, the better our customers are able to monitor their sites,” comments McKinnon.

He had a fondness for the recently launched Sony QX-1, which despite being compact and lightweight (180g) has a large 20 mega pixel APS-C image sensor that is 15 times larger than the GoPro and features an exceptional signal to noise ratio to deliver superior image quality in all light conditions.

“I took one of these QX-1 cameras with the Solo and went into the garage on the weekend and prototyped a crazy contraption that connects the camera via software and hard cable to our drone.

“This feat of engineering contains no fewer than two Pixhawks, six batteries, 20+ feet of cable, two companion computers, five ESCs, 10+ feet of strapping tape, two transmitters and a RC Timer CM102 camera gimbal,” smiles McKinnon.

He photographed the prototype and wrote a post on DIYDrones.com, which was in fact started by 3DR’s CEO in 2007 and has since grown into the world’s largest open robotics development community. Having received a positive response from the community, he ran the idea past a few customers, who also responded positively, before deciding to pursue it by contacting Sony directly.

Getting Sony onboard

John Monti, director of Visual Imaging Solutions at Sony Electronics, was impressed and arranged for McKinnon to have a face-to-face meeting with the top executive in Sony’s camera engineering organisation, who was visiting an unrelated trade show in the US.

“During the presentation and with the conference table literally covered with circuit boards, cables, lenses, etc. Dan patiently explained what was needed to create a simple and elegant solution. In the end, the gambit left a strong impression on Sony’s executive as well as the team of key marketing and planning folks and the meeting literally changed Sony’s thinking on the market potential for commercial drone cameras,” says Monti.

“It was quite a surreal experience for this top guy from Sony to see me pull stuff out of the case to see what monstrous contraption I’d created to integrate this off the shelf camera with our drone,” laughs McKinnon.

Following a visit to the Site Scan team at 3DR’s facilities, the Sony team responded a few weeks later with a proposal that met the requirements without having to develop a totally new product from the ground up. “They built us a custom version called R10C and wrote some special software. We then wrote our own software and built a stabilisation gimbal for the camera,” says McKinnon.

According to Monti, the creation of the two axis gimbal would take considerable mechanical design expertise since the Solo will fly with two different Sony lenses, one of which has a remotely-controlled power optical zoom function, changing its centre of mass and physical size as it zooms in and out.

Civil engineering and design firm Kimley-Horn used Site Scan recently to scan the Red Rocks Amphitheatre in Colorado, which resulted in a highly detailed and sharp 3D model of the site

Brushless vs servo motors

Matt Ambauen was the lead mechanical engineer on the project and hit the ground running as the timeline was extremely tight.

“We initially had planned to do a gimbal based around DC brushless motors, similar to the product we had on the market already, but the weight of the brushless motors would have pushed the stabilisation system over the maximum payload,” he claims.

The R10C is not a light unit and its centre of gravity actually changes pretty drastically, especially with the zoom lens. As brushless gimbals are very sensitive to balanced payloads, Ambauen decided to resurrect an older technology in the form of high-end servo motors.

These motors are coupled to a sensor for position feedback so although it may not be ideal for delivering high quality video, it is more than capable of stabilising the camera stills, which is what the Site Scan user would be interested in anyway.

“Servos are not as smooth as the DC brushless motors would have been – it’s a little jerkier than what we would have liked but since we were taking stills as opposed to video, it was a concession we were willing to make. Any jitter in the gimbal would be really slow relative to the fast frame rate of the camera,” comments Ambauen.

The benefit of using servo motors was also that the whole system would be lighter as it wouldn’t need any additional components like motor control boards or encoders that would be needed if a brushless gimbal was used. Of course, weight is a major consideration in the development of drones because any excess can cause them to perform negatively.

“There is an autopilot that is doing the stabilisation and trying to keep the vehicle in the air and if it doesn’t have the control forces needed to do that, you start to drift all over the place.

The camera is actually quite heavy and was approaching the maximum payload for the vehicle so we had to keep the gimbal component of it as light as possible so we didn’t go past the controllable payload for the quadcopter,” explains Ambauen.

The Sony UMC-R10C is available now, completely integrated with the Site Scan app on iOS. The total package is available for $12,200 including the drone, camera, software and full support

Gimbal design process

Having decided on the use of servo motors, Ambauen kicked off the gimbal’s design process by importing the step files that Sony had provided into SolidWorks.

“We only had to interface with a couple of faces of the camera and I spent a reasonable amount of time trying to design these interfaces directly with the camera off the CAD. The geometry wasn’t a 100 per cent correct so we had to iterate and used 3D printing a lot for that.

“We would tweak some dimensions and print a new piece to see how it fits against the camera and then try again if it wasn’t quite right. It took four or five iterations to dial it in,” describes Ambauen.

Meanwhile, the 3DR software team had been working on the software development side of things and at the start of September 2016 the company announced the availability of Site Scan as an integrated bundle with Sony’s UMCR10C camera.

“I’m really proud of the work we have done with Sony and the team to build the best flying camera in the sky, it’s well above anything the competition is offering. On top of that we are offering unparalleled customer service with a dedicated support team available to guide our customers through the Site Scan process and to be on hand to answer any questions,” says McKinnon.

Although it’s still early days, 3DR has racked up a number of Site Scan customers already (see box out below), and with other industries seeing the applicability of drones to what they do, this is only going to increase.

One of Site Scan’s first customers was US veteran Quentin Wheeler who, having experience of military drones, knew that this technology would be transferrable to many industries. So, in 2015 he founded Applied Drone Systems to offer mapping and surveying services to construction companies.

In fact, he was utilising the Solo drone in this commercial capacity before it was even integrated with the Site Scan solution.

“From the very beginning, the 3DR Solo platform was built with upgrades in mind on both the hardware and software side. The drone is very modular and every software upgrade has worked flawlessly with the hardware resulting in increased capabilities for the drone,” says Wheeler.

When 3DR announced the Site Scan app and its integration with the Autodesk ReCap 360 cloud, Wheeler knew it would be a game changer. “I had mastered the video side of 3DR Solo but knew there were more opportunities available for drones.

With the Site Scan launch, the door was opened to these increased opportunities in a well thought out complete package with business endusers in mind,” he says.

In terms of operating the drone, Wheeler claims it is very straightforward. After a couple of flight profiles all the data has been collected and is transferred to the cloud for initial processing.

“I love to be able to keep all my missions and final models in the same spot in the cloud and to be able to share them easily with the client. We can access and process our data from anywhere,” he adds.

3D Robotics brings Site Scan to the skies

Default